As a smart hydration specialist, I spend a lot of time helping families understand why their reverse osmosis (RO) system behaves differently in winter versus summer, or why the installer insisted on connecting only to the cold line. Temperature is not just a comfort preference at the faucet. It is a major performance variable inside every RO membrane.

On paper, warm water looks tempting. It flows more easily, pushes through RO membranes faster, and can give you a higher gallons-per-day number at the same pressure. Several technical references from water treatment manufacturers confirm that membrane production rises as temperature rises and falls when water gets colder. Yet when you zoom out and look at overall efficiency, health, and system life for a home drinking-water system, cold-water RO designs usually win.

This article walks through the science, the trade-offs, and the practical choices behind cold versus hot operation so you can run your system in a way that is efficient, safe, and aligned with long-term water wellness in your home.

How Reverse Osmosis Works In Your Kitchen

Reverse osmosis is a pressure-driven filtration process. Instead of relying on gravity or simple strainers, it pushes water through a semi-permeable membrane with incredibly small pores, around 0.0001 microns in many residential designs. That pore size is fine enough to block a wide range of dissolved substances while allowing water molecules to pass.

Most point-of-use RO systems under a kitchen sink follow a similar pathway. A sediment pre-filter catches sand, rust, and dirt. A carbon pre-filter reduces chlorine and many organic chemicals that could otherwise damage the membrane or affect taste. The RO membrane then removes most dissolved salts and contaminants. A final polishing carbon filter often improves flavor before the water reaches your dedicated drinking faucet.

Independent reviews and manufacturers report that even basic RO units can reduce contaminants such as lead, arsenic, sodium, chloride, copper, chromium, nitrate, and many other dissolved solids. According to CDC guidance cited by RO brands, this makes RO particularly useful for households with compromised immune systems or specific contaminant concerns. Many modern systems also display total dissolved solids (TDS) in real time, so you can see how “clean” your water is after treatment.

The trade-offs are important to understand. RO:

Removes beneficial minerals such as calcium and magnesium along with problem contaminants, as highlighted in reports summarized by Newater, Pureway Filtration, Brio, and Puresoft Water. A World Health Organization review noted that very low-mineral water is not ideal as the only drinking source unless minerals are obtained elsewhere.

Wastes water to drain. EPA data cited by Brio suggest that a typical under-sink RO system may send roughly 5 gallons of concentrate to drain for every 1 gallon of product water, with some older or less efficient designs wasting even more.

Requires regular maintenance. Multiple sources recommend replacing sediment and carbon pre-filters every 6–12 months and membranes every 1–3 years, depending on water quality and usage.

Within that framework, temperature quietly sits in the background, changing how much water you get, how hard your system works, and how long the membrane lasts.

Where Temperature Fits Into RO Performance

Viscosity, Membrane Pores, And Flow

Several technical articles from Aquatic Life, APS Water, Aqualitek, and Salt Separation Services agree on the core physics: as water gets colder, it becomes more viscous. Many users describe this as water getting “thicker.” At higher temperatures, water becomes “thinner” and flows more easily.

An RO membrane has a dense, spiral-wound thin-film composite layer made from polyamide. The pores are extremely small, in the 0.0001 to 0.001 micron range, and water moves through them under pressure. Temperature affects this process in two main ways.

First, viscosity. Cold, “thicker” water encounters more resistance as it tries to pass through the membrane. Flow slows down unless feed pressure is increased. Warm, “thinner” water slips through more easily, so permeate production goes up at the same pressure.

Second, membrane structure. As Salt Separation Services explains, membrane pores tend to expand at higher temperatures and contract at lower temperatures. When the pores expand, permeability increases, so more water can pass through at lower pressure, but salt rejection usually decreases and the permeate TDS rises. At lower temperatures, the pores contract, effectively tightening the membrane. This improves salt rejection and permeate quality but requires higher pressure to overcome osmotic and hydraulic resistance.

So the basic pattern is straightforward.

Warmer water speeds up production but slightly relaxes filtration; colder water tightens filtration but slows production and demands more pressure.

The Industry’s Standard Temperature Benchmarks

Because temperature has such a strong effect, membrane makers had to pick a reference point. Across the sources from Aquatic Life, APS Water, Aqualitek, and PureWaterProducts, that number is consistent. Residential and commercial RO membranes and systems are rated at a standard feed-water temperature of about 77°F.

All of the published gallons-per-day ratings you see in brochures assume 77°F feed water and a specified pressure, often around 60–65 psi for residential membranes. In real homes, feed temperature can be much lower, especially in winter. That is what causes the familiar “my RO used to be fine, now it is slow” complaint.

APS Water and Aquatic Life both describe a simple rule of thumb to estimate the effect. For each degree Fahrenheit below 77°F, product flow drops by roughly 3 percent. For each degree warmer than 77°F, flow rises by a similar amount. That rule is not exact, but it lines up with temperature-correction tables used by membrane manufacturers.

One Aquatic Life example is especially clear. A membrane rated at 50 gallons per day at 77°F and 65 psi produces only about 26 gallons per day at 50°F when you apply the manufacturer’s temperature correction factor. That is almost a 50 percent reduction just from colder water.

Nothing is wrong with the membrane; the water is simply colder and more viscous.

To make this easier to visualize, here is a simplified comparison based on that example.

Feed temperature (°F) |

Approximate status vs rating |

Example permeate from a “50 GPD at 77°F” membrane |

Notes |

77 |

Baseline rating |

50 gallons per day |

Standard industry test condition |

50 |

Much lower than rating |

26 gallons per day |

Manufacturer temperature-correction factor around 0.52 |

Below 41 |

Often below typical residential rating range |

Variable but significantly reduced |

Many commercial and residential membranes are not rated for extended operation below about 41°F |

The bottom line: cold water does not damage the membrane by itself, but it can easily cut production by 30–50 percent and make a perfectly healthy system look “weak.”

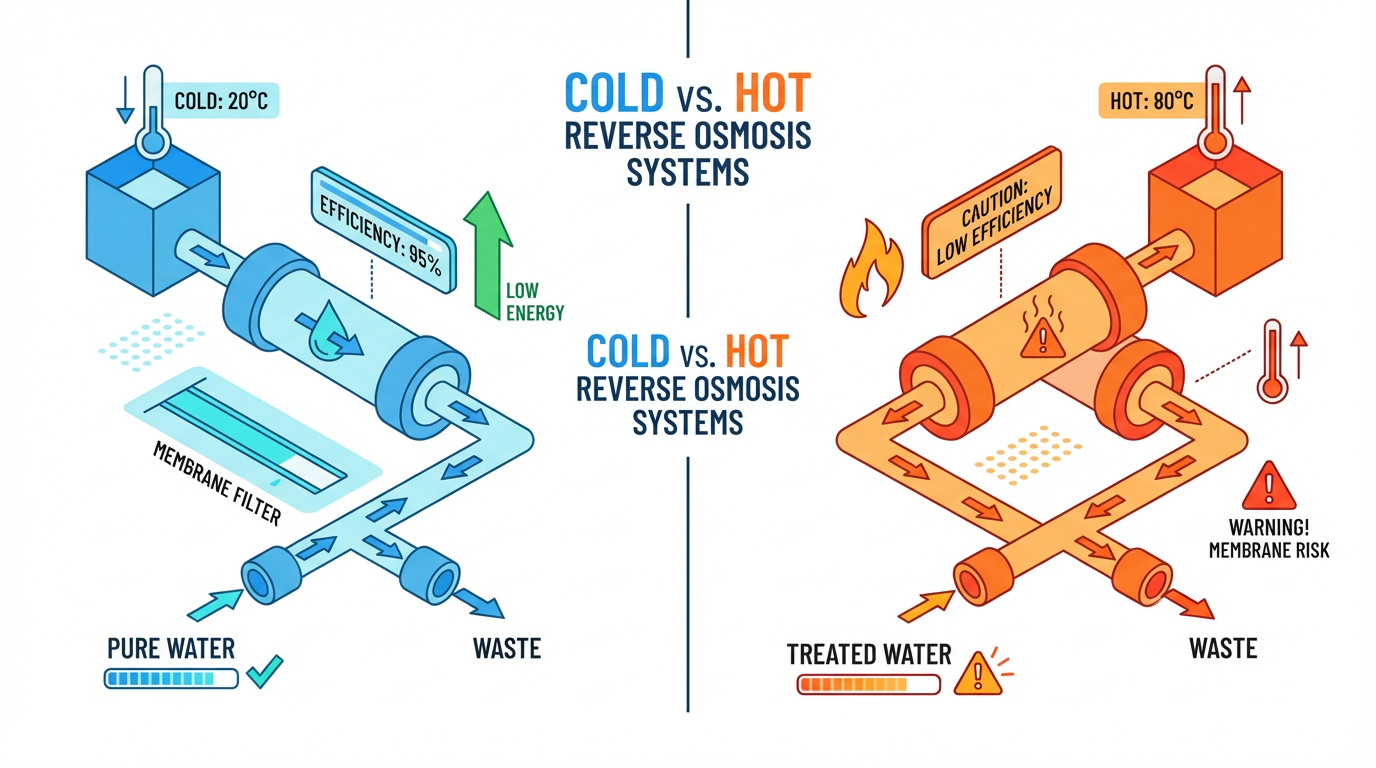

Cold Versus Hot: What “Efficiency” Really Means

It is tempting to look at those numbers and conclude that hotter must always be better. After all, if a small temperature increase can boost flow by several percent per degree, why not feed the RO from the hot side and enjoy rapid production?

To answer that, we need a broader definition of efficiency. For a drinking-water system in a home, efficiency is not just gallons per day. It is a combination of water quality, water waste, energy use, membrane and component life, and maintenance costs over many years.

Water Production Rate

On pure production rate, warm water wins. At a constant pressure, a membrane will produce more gallons per day at 80°F than at 60°F. Several technical notes from Aqualitek and Waterlux explain that around 68–77°F is often considered an “ideal” operating band for many commercial and industrial membranes. Slightly warmer water within the manufacturer’s limits makes systems feel more productive.

However, the gain is only one piece of the picture. Warmer water also:

Reduces salt rejection slightly. Aqualitek points out that as temperature rises, more ions pass through the membrane and permeate TDS increases. That is critical in high-purity RO and RO/DI applications such as pharmaceutical production, electronics, and medical cleaning, where even small TDS changes matter.

Shifts fouling behavior. Higher temperatures accelerate biological activity and chemical reaction rates, which can increase the risk of biofouling and scaling. Lower temperatures suppress some biological growth, though they can promote certain precipitates if water chemistry is unstable.

For home drinking water, modest seasonal changes around room temperature are usually acceptable. The question is not whether a bit of warmth is harmful; it is whether intentionally feeding hot water to “improve” an under-sink RO is a good idea. The evidence suggests it is not.

Energy Use And Operating Stress

When you feel an RO slowing down in winter, there are two ways to respond. You can heat the feed water, or you can optimize pressure and system design while accepting that colder water naturally produces less.

Technical references from APS Water, Aqualitek, PureWaterProducts, and Fileder emphasize pressure as the primary design lever. If pressure drops, permeate flow falls even at constant temperature. Long or undersized feed lines, elevation, and low municipal or well pressure all reduce net driving pressure. Solutions such as larger-diameter lines, shorter runs, or a small booster pump are proven ways to raise production without stressing the membrane with temperature extremes.

Heating feed water, on the other hand, adds energy cost and system complexity. Industrial RO/DI systems that intentionally use hot water rely on robust heaters, insulated piping, and careful material selection to manage the extra thermal and corrosion stress. That is different from simply tapping into a household water heater.

From an efficiency standpoint, a cold-water RO system that stays within the membrane’s comfort zone and uses good pressure management is usually the smarter choice than a hot-water setup that chases a faster flow with higher energy and hardware costs.

Water Quality And Salt Rejection

There is also a quiet quality advantage to colder operation. Salt Separation Services notes that when feed temperature drops and pores contract, the membrane provides finer filtration. Salt rejection improves and permeate quality goes up, at the cost of needing more pressure.

Aqualitek echoes this, explaining that permeate flow rises in the 86–95°F range but salt rejection declines slightly, which matters in high-purity environments. That same physics applies in your kitchen. If you were to push your residential membrane toward the top of its temperature rating to maximize gallons per day, you could be trading away a bit of the very purity you installed the system for.

Most families will not notice small TDS shifts on the tongue, especially if the water is remineralized afterwards. But if your goal is genuinely low TDS and strong contaminant reduction, slightly cooler operation within the rated range leans toward more efficient removal rather than just more volume.

Membrane Life, Corrosion, And Safety

Hot water is harder on RO membranes and materials. Salt Separation Services describes how operating beyond a membrane’s specified upper temperature limit can cause structural degradation over time. This can include compaction of the membrane layers or intrusion of the composite into the permeate carrier, both of which reduce performance and shorten membrane life.

Aqualitek notes typical temperature limits for many commercial and industrial RO membranes around 41–95°F, with some specialized products rated up to roughly 113°F. Prolonged operation above those limits is associated with permanent damage and possible system failure.

The Hubbell discussion of heated RO/DI cleaning water adds another important dimension: heated high-purity water is significantly more corrosive than cold RO/DI. It behaves like an aggressive solvent, attacking incompatible metals and seal materials. That is excellent for stripping soils off medical implants or semiconductor parts, but it demands heaters and wetted components specifically designed for that environment.

Most residential under-sink RO systems are not built with that level of corrosion protection. Feeding them hot water routinely pushes them into a regime they were not designed to handle, eroding membrane life and potentially stressing housings, fittings, and tubing. From a long-term efficiency standpoint, that is a poor trade-off.

Why Feeding RO With Hot Water Is A Bad Idea In Homes

RO experts and manufacturers consistently warn against connecting residential membranes to hot water lines or directly blending with hot water from a household heater.

Aquatic Life is explicit. They highlight that RO membranes cannot tolerate temperatures above about 100°F, yet household water heaters often run hotter than that. Beyond temperature, water heaters commonly accumulate silt, sediment, and corrosion byproducts in the tank. Feeding that directly into your RO will increase fouling and can physically damage both the membrane and the housings.

PureWaterProducts describes a related scenario. They acknowledge that raising feed water temperature, as long as you stay under roughly 95°F, can increase production. However, they caution against using water from a heater when the product water is for drinking. Instead, they suggest passive options such as coiling feed tubing so water can warm to room temperature rather than pulling from the hot line.

These practical warnings align with the industrial perspective from Hubbell. If you want to run hot RO or RO/DI water reliably, you need:

Heaters and heat exchangers designed for high-purity service.

Carefully chosen wetted materials that can handle hot, corrosive water.

Rigorous monitoring of temperature and resistivity.

That level of engineering and cost is not realistic for a typical under-sink drinking-water system.

The safer, more efficient design is to connect only to the cold line, operate within the membrane’s recommended band, and treat temperature as a variable to monitor rather than a knob to turn aggressively.

Cold-Water RO In The Real World: Seasonal Performance

Even when you do everything “right” and stay on the cold line, temperature still shows up in daily life, especially in colder regions and in winter.

Many membrane and system manufacturers report the same pattern. In cold months, feed water can arrive at the RO at 50°F or even lower. Using Aquatic Life’s example, that can cut a nominal 50-gallon-per-day membrane down to roughly half its rated production even with good pressure. APS Water stresses that if you do not adjust for temperature using a correction factor, you might mistakenly think your membrane is failing when it is simply running cold.

PureWaterProducts provides a detailed case study. A homeowner with a 75-gallon-per-day membrane was only seeing about 15 gallons per day in practice. When a technical editor corrected for the lower feed temperature, modest pressure, elevated TDS, and tank backpressure, the calculated output landed right around 16 gallons per day. In other words, the system was performing as physics predicted. The rating on the brochure never described real-world conditions.

This is where cold-water systems show their efficiency in an everyday sense. Rather than trying to “fix” winter slowdown with hot water, the smart move is to:

Understand that colder feed water naturally reduces output.

Use temperature correction factors to distinguish normal seasonal variation from true membrane fouling.

Design for your coldest realistic feed temperature when sizing membranes, tanks, and, if needed, booster pumps.

That approach protects your membrane, preserves water quality, and aligns your expectations with what the system can safely deliver year-round.

Practical Ways To Make A Cold-Water RO System More Efficient

If you accept that hot feed water is not the right answer for a home RO, what can you do to make a cold-fed system as efficient and user-friendly as possible?

Optimize Pressure Instead Of Temperature

Because RO is a pressure-driven process, improving pressure within safe limits is often the most effective way to reclaim performance lost to cold feed water.

Several sources, including Aqualitek, APS Water, PureWaterProducts, and regional water treatment providers, recommend:

Checking incoming pressure at the RO feed. Many residential systems are sized around 50–65 psi. If your home sits on a hill, shares a line, or has older plumbing, you might see significantly less.

Minimizing pressure losses within the plumbing. Long, narrow feed lines reduce effective pressure at the RO. Upsizing the line diameter or shortening unnecessary loops can reduce these losses.

Adding a small booster pump when needed. In low-pressure homes or in climates with very cold feed water, a dedicated booster pump can restore net driving pressure and bring permeate flow back toward the membrane’s rated performance without resorting to heating.

This strategy takes advantage of the membrane’s design instead of pushing it beyond its thermal comfort zone.

Protect The System In Cold Spaces

Not every RO lives in a cozy kitchen cabinet. Some are in basements, utility rooms, garages, or crawl spaces where temperatures can approach freezing. Cold-environment guidance from Aqualitek, Fileder, and Clear Water Filtration emphasizes that freezing is a much more serious risk than simple viscosity changes.

Water expands as it freezes. Any water trapped in housings, pumps, or membrane vessels can crack the plastic or metal as it turns to ice. To avoid this:

Install the unit indoors in a conditioned space whenever possible.

Insulate exposed lines, housings, and tanks, especially in unheated basements or exterior walls.

Consider heat tracing or small space heaters in very cold climates, following safety guidelines, to keep system temperatures safely above freezing.

Drain or bypass outdoor or seasonal systems before extended periods of hard freeze.

These steps do not necessarily make the water much warmer at the membrane, but they protect the hardware from catastrophic freeze damage and keep your RO operating safely as a cold-water system.

Plan For Winter Output

If your coldest feed water will cut RO production in half, planning becomes part of efficiency.

You can:

Use a storage tank sized for your household’s daily drinking and cooking needs, especially if you have high usage mornings or evenings.

Schedule high-demand tasks like filling pitchers or cooking pasta at times when the tank is likely to be full, not immediately after heavy use.

Accept that a system tuned for safe cold-water operation might fill a bit slower in winter than in summer and design your routine around that, rather than oversizing or overheating the membrane.

EPA information summarized in several consumer articles reminds us that RO systems already waste more water than simpler filters because of the concentrate stream. Trying to “force” more flow with hot water does not remove that waste; it simply adds more stress. Planning around realistic cold-water performance is an efficient, low-risk path.

Maintain Water Quality And Mineral Balance

Regardless of temperature, RO’s core job is to give you cleaner, safer water. Proper maintenance is a key part of that efficiency picture.

Multiple sources, including Brio, Reliable Air, Pureway Filtration, Puresoft Water, and Newater, recommend:

Replacing sediment and carbon pre-filters every 6–12 months, depending on use and water quality. This keeps the membrane protected from chlorine and particulates.

Replacing the RO membrane every 1–3 years, or according to TDS and flow performance, to maintain contaminant reduction.

Checking for leaks and confirming that the system’s first set of replacement filters is on hand or included.

Because RO removes virtually all minerals, including beneficial calcium and magnesium, you should also think about mineral balance. World Health Organization commentary and several consumer-focused articles point out that very low-mineral water is not ideal as the only source of hydration unless your diet compensates.

Practical options include:

Ensuring your daily diet includes mineral-rich foods.

Using a remineralization cartridge that adds back a modest amount of calcium and magnesium after the RO membrane, primarily for taste and minor mineral support.

These steps help you enjoy the purity benefits of cold-water RO while keeping your hydration nutritionally balanced.

Pros And Cons Of Cold-Water RO For Home Hydration

When you put all of this together, a clear picture emerges.

On the positive side, a cold-fed RO system delivers very high contaminant reduction, better taste and odor, and a reliable supply of drinking water without depending on bottled water. It operates within the membrane’s designed temperature range, which protects the membrane structure, avoids excessive corrosion, and supports long service life. Cold operation tends to preserve or slightly improve salt rejection compared with hotter operation, supporting lower TDS at the tap.

On the trade-off side, cold water reduces production, sometimes drastically in winter, especially in regions with very cold incoming water. Homeowners who expect brochure-rated gallons per day year-round can be disappointed. RO also wastes several gallons of water for every gallon produced, and it strips beneficial minerals along with contaminants, which you may want to address through diet or remineralization. Finally, the system requires regular maintenance and, in cold climates, some attention to freeze protection.

Compared with hot-water RO or attempts to feed a standard residential membrane from a household water heater, cold-water RO systems are usually more efficient in a holistic sense. They avoid membrane damage, protect housings and fittings, maintain better salt rejection, and do not demand corrosion-resistant industrial heaters and piping. They may not win every “gallons per day” contest in the lab, but over years of real-world use, they align much better with safe, sustainable home hydration.

FAQ

Can I Connect My RO System To The Hot Water Line To Get More Flow?

You should not connect a standard residential RO system to the hot water line. Membrane manufacturers, and experts summarized by Aquatic Life and PureWaterProducts, warn that temperatures much above about 95–100°F can damage thin-film composite membranes. Household water heaters are often set hotter than that and can contain sediment and corrosion byproducts that foul the membrane. If your RO is slow, focus on measuring feed temperature and pressure and consider a booster pump rather than adding heat.

Does Cold Water Make My RO Water “Cleaner”?

Colder feed water does not magically remove new contaminants, but it does tend to tighten the membrane. Technical notes from Salt Separation Services and Aqualitek describe how pore contraction at lower temperatures improves salt rejection and can lower permeate TDS, at the cost of lower flow and higher pressure requirements. For typical home users, that means cold operation within the rated range supports strong contaminant reduction, even if you notice slower production.

How Do I Know If My Slow RO Is A Temperature Problem Or A Membrane Problem?

Start by measuring or estimating your feed water temperature. If it is far below 77°F, use the rule of thumb from APS Water and Aquatic Life that production drops about 3 percent for every degree Fahrenheit below 77°F to estimate how much slowdown is simply temperature. If the temperature-corrected performance is still far below expectations, check feed pressure, pre-filter condition, and tank backpressure. Only when those are in line and the system is still underperforming is membrane fouling the likely culprit.

Cold-water RO systems succeed because they respect these realities. They lean on good pressure, smart design, and thoughtful maintenance instead of pushing membranes with hot water. If your goal is healthy, great-tasting hydration with minimal surprises over the long term, that is the kind of efficiency that truly matters.

References

- https://www.ewg.org/news-insights/news/reverse-osmosis-water-filters-when-are-they-good-choice

- https://ida.memberclicks.net/assets/docs/1099.1.pdf

- https://www.apswater.com/article.asp?id=181&title=Reverse+Osmosis+Systems+Flow+Rate+Changes+With+Temperature

- https://www.aqualitek.com/best-guide-how-inlet-water-temperature-affects-an-ro-system-insights-by-aqualitek.html

- https://saltsep.co.uk/the-impact-of-water-temperature-on-reverse-osmosis-systems

- https://www.puresoftwatertreatments.com/pros-and-cons-of-reverse-osmosis-water-puresoft-water

- https://espwaterproducts.com/pages/reverse-osmosis-advantages-and-disadvantages?srsltid=AfmBOoqnNvVmC6-2pd2rBvudx_T8ySW4XfqMOZ2njPiI4ZhlsQ61duO1

- https://www.newater.com/reverse-osmosis-water-pros-cons/

- https://www.purewaterproducts.com/articles/ro-membrane-production

- https://purewayfiltration.com/the-pros-and-mostly-cons-of-reverse-osmosis-filtration/

Share:

Understanding Acceptable Error Tolerance for Smart TDS Monitors

Understanding Acceptable Error Tolerance for Smart TDS Monitors