As a smart hydration specialist, I see the same pattern over and over: people invest in a great reverse osmosis (RO) system, enjoy crisp water for a year or two, and then slowly accept weaker flow, flat taste, and higher maintenance costs as “normal.” In nearly every case, the root issue is the same: the RO membrane is being cleaned too late, too rarely, or in the wrong way.

Dialing in your membrane cleaning frequency is one of the highest‑leverage things you can do to protect both water quality and your wallet. The good news is that you do not need a lab or an industrial controls team to get it right. With a basic understanding of how fouling shows up in real numbers and in day‑to‑day use, you can move from guesswork to a simple, data‑driven routine.

In this guide, I will pull together evidence from residential water experts, industrial membrane manufacturers, and even cutting‑edge research to show you how to choose and adjust the right cleaning frequency for your RO membrane at home or in a light commercial setting.

How RO Membranes Work – And Why Cleaning Frequency Matters

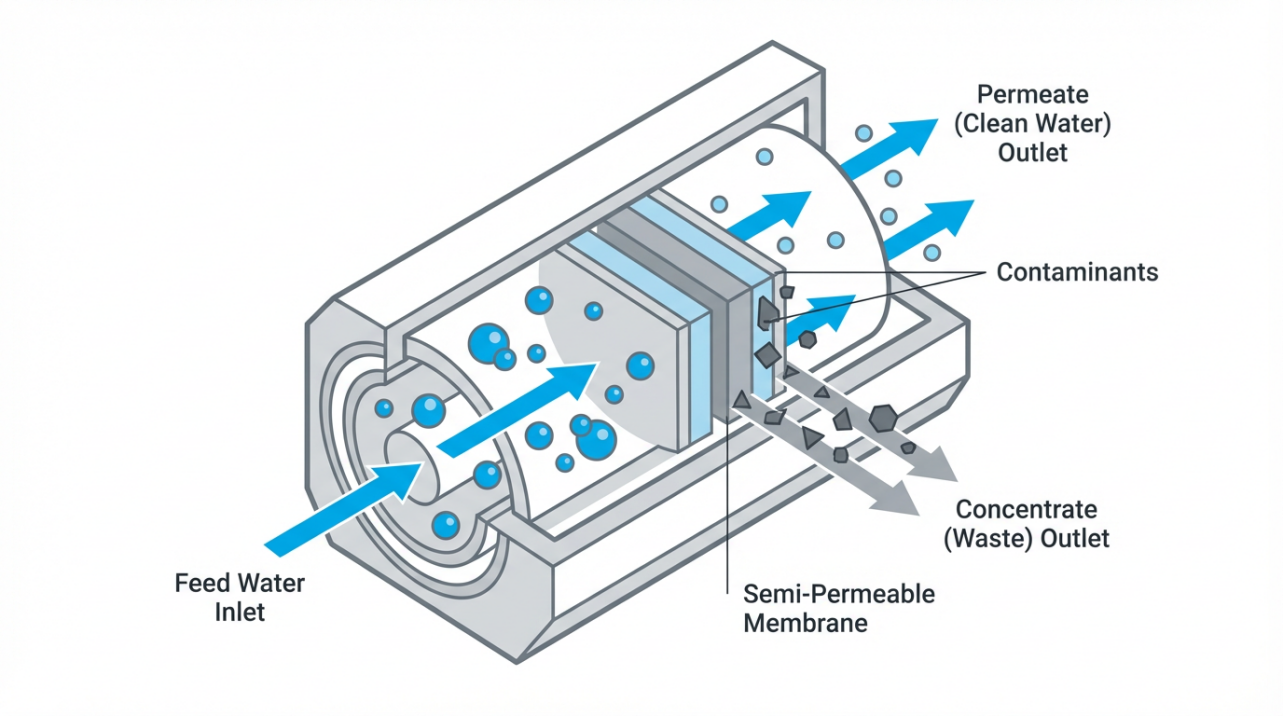

A reverse osmosis system pushes water under pressure through a semi‑permeable membrane. That membrane lets water molecules pass while rejecting most dissolved minerals, metals, and many other contaminants. University of Nebraska Extension notes that household RO units typically produce around 10 to 35 gallons of treated water per day, and they can significantly reduce substances like lead, nitrate, fluoride, sulfate, and many pesticides.

The membrane is the heart of the system. Over time, it gradually loads up with what professionals call “foulants”:

- Mineral scale from hardness and metals

- Organic matter and biofilm

- Fine particles and colloids

- Microbial growth if the system is not sanitized regularly

As fouling builds, several things happen at once. Permeate flow (the clean water side) drops, differential pressure across the membrane rises, and salt rejection slowly declines. You feel this as a weaker stream at the RO faucet, water that starts to taste “off,” or a system that runs constantly but never seems to fill the storage tank.

Residential providers such as Angel Water and Crystal Quest emphasize that with good maintenance, an RO system can last about 10 to 15 years, while the membrane itself can often serve for 2 to 5 years. Industrial sources, including DuPont, report well‑treated membranes lasting around 6 years in demanding plants. The thread connecting all of these numbers is straightforward: fouling will happen, and the way you clean and protect the membrane determines how long it stays efficient.

Cleaning too infrequently lets fouling harden into a compact layer that chemicals can no longer fully remove.

Cleaning too aggressively or too often exposes the membrane to harsh pH and higher temperatures that accelerate aging. Optimizing frequency is about finding the point where you clean early enough to maintain performance, but gently enough to preserve membrane life.

What Counts as “Cleaning” for an RO Membrane?

Before we talk frequency, it helps to separate three related but different tasks that often get lumped together as “cleaning”:

Membrane chemical cleaning. This is what most industrial sources call Clean‑In‑Place (CIP) or, for smaller systems, removal and soaking. Specialized low‑pH and high‑pH cleaners are circulated or used to soak the membrane to remove scale, organic fouling, and biofilm. Kurita America and Crystal Quest describe this as using low‑pH cleaners for mineral scale and high‑pH cleaners for organic and biological foulants. This is the central topic when you optimize “cleaning frequency.”

System sanitization. Many home maintenance guides, including Crystal Quest and Culligan, recommend annual sanitization using an appropriate disinfectant (commonly a small amount of bleach or hydrogen peroxide), flushing it through the lines and storage tank, and then rinsing thoroughly. This is mainly about microbial control and hygiene, not deep descaling of the membrane.

Filter replacement. Sediment and carbon pre‑filters protect the membrane from particulates and chlorine, and post‑filters polish taste. Angel Water, Alamo Water Softeners, and others recommend replacing these pre‑ and post‑filters roughly every 6 to 18 months, depending on water hardness, whether you have a softener, and usage.

In practice, you will often combine these tasks during the same service visit, but it is helpful to remember that membrane cleaning frequency can be adjusted separately from simple filter changes and annual sanitization.

Performance‑Based Signals That It Is Time to Clean

The most reliable way to decide when to clean a membrane is not the calendar at all. It is performance data. Industrial and municipal plants rely on normalized performance metrics and clear thresholds, and you can borrow the same logic at home on a simpler scale.

Key metrics and typical cleaning triggers

Several reputable technical sources converge on similar trigger points:

Metric |

Common trigger range |

Example sources |

Normalized permeate flow |

About 10–15% decrease from baseline |

Kurita America, Complete Water Solutions, Chunku, DuPont guidance summaries |

Differential pressure (feed to concentrate) |

About 15–20% to 50% increase, depending on guidance |

Kurita America, Complete Water Solutions |

Salt rejection or TDS reduction |

About 2–10% decrease from baseline |

Kurita America, Complete Water Solutions, RO cleaning guides |

Complete Water Solutions recommends cleaning when normalized permeate flow has dropped 10 to 15%, differential pressure has increased by about 50%, or salt rejection has declined by at least 2%. Kurita America and other membrane‑cleaning specialists suggest similar thresholds, often 10% lower flow and about 15% higher differential pressure. A technical discussion on Eng‑Tips warns that if you wait until normalized performance has fallen 30 to 50%, full recovery may be impossible, even with aggressive cleaning.

For a home user, you may not normalize data to account for water temperature, but you can still track the basics:

Clean water flow. Time how long it takes to fill a fixed glass or pitcher when the membrane is freshly installed or freshly cleaned. If it takes around 20% longer under similar conditions, that is a strong sign of fouling.

TDS reduction. Use a simple TDS meter to compare tap water and RO water. Crystal Quest notes that good RO performance typically yields around 90% lower TDS than the feed. A window‑cleaning community uses the same idea to judge membrane health by “rejection rate.”

Differential pressure and gauges. If your system has inlet and concentrate pressure gauges, watch the difference. Rising differential pressure at the same feed pressure is a textbook sign of fouling packing into the membrane channels, as described by Complete Water Solutions and Kurita America.

A simple rejection calculation example

One community example for professional window cleaning looks at a feed TDS of 300 parts per million (ppm) and an RO output of 5 ppm. The rejection percentage is calculated as:

Rejection = (300 − 5) ÷ 300 = 295 ÷ 300 ≈ 0.983, or about 98.3%.

In practice, that rejection rate means the membrane is still performing very well.

As the membrane ages and fouls, you might eventually see something more like 300 ppm in and 30 ppm out. That would be 90% rejection, which is still acceptable for many household applications but clearly worse. If you see that drop happen over a few months instead of a few years, it is time to revisit both cleaning frequency and pretreatment.

How Often Should You Clean a Home RO Membrane?

Now that we have performance triggers, how do they translate into an actual cleaning schedule for a typical under‑sink RO system?

Consumer and light‑commercial guidance is surprisingly consistent once you adjust for water quality and usage:

Crystal Quest’s dedicated cleaning guide suggests cleaning the membrane about every 6 to 12 months or whenever you notice performance decline such as lower faucet output, rising TDS, or taste and odor changes. Aqua‑Wise, in a DIY cleaning article, notes that typical RO systems require membrane cleaning every 3 to 12 months depending on application. Frizzlife, in a maintenance overview, recommends general system cleaning every 6 to 12 months, with the membrane inspected roughly every 2 years and replaced if damaged. Alamo Water Softeners points out that when an RO system is paired with a water softener, filters and sanitization can often be done every 12 to 18 months, and membranes commonly need replacement around every 3 years. Without a softener, they recommend more frequent service: filters and sanitization every 6 to 9 months and membrane replacement annually.

Putting this together, a reasonable starting point for a typical home on municipal water looks like this:

Membrane cleaning check at 6 to 12 months. If flow, taste, and TDS are still strong, especially when you have good pretreatment and soft water, you may extend toward the longer end. If performance has drifted, schedule a chemical cleaning following your manufacturer’s method.

Annual full system sanitization. Many providers, including Angel Water, Crystal Quest, Culligan, and CalSoft, recommend at least yearly sanitization and filter changes. On that same visit, it is smart to review membrane performance and decide whether cleaning or replacement makes more sense.

Membrane replacement about every 2 to 4 years. Angel Water and Crystal Quest both place typical membrane replacement in the 2 to 3 or 2 to 4 year range under normal conditions, with high‑quality systems and softened water sometimes stretching toward 3 to 5 years.

Remember that these are not rigid rules.

A high‑use café with hard well water may genuinely need membrane cleaning on the short end of the 3 to 12 month band. A small household on softened city water that uses RO only for drinking and cooking might comfortably clean less often, as long as performance data and water quality remain stable.

Cleaning Too Often vs Not Often Enough: Finding the Sweet Spot

Industrial experts spend a lot of time on exactly this trade‑off, because cleaning and replacing dozens or hundreds of membranes is expensive. The same logic holds, scaled down, for your home system.

A technical guide from Kurita America and a professional discussion on Eng‑Tips highlight two key realities:

Cleaning early, when fouling is light, gives the best recovery. Once the foulant layer becomes thick and compact, chemicals have a hard time penetrating. Eng‑Tips contributors note that if you let normalized performance fall 30 to 50% below baseline before cleaning, some loss may be irreversible.

Aggressive cleaning conditions can shorten membrane life. Pushing pH, temperature, or contact time beyond the membrane manufacturer’s limits can improve foulant removal but accelerate hydrolysis and mechanical stress. Industrial guides emphasize staying within specified pH bands and temperatures, often around pH 1 to 12 and below roughly 86 to 113°F depending on membrane type.

So what does this mean for a homeowner or small business owner?

It means that “wait until it is obviously bad” is a poor strategy, and “scrub it with the harshest chemicals every month” is just as problematic. A better pattern, supported by sources like Kurita America, Complete Water Solutions, and Aqua‑Wise, is to clean when the first clear performance thresholds are crossed, using the mildest effective chemistry and correct temperature for your specific membrane.

This is also where pretreatment and system design have a huge influence. DuPont describes an industrial plant that extended the time between cleanings from an average of about 22 days to roughly 52 days by switching to fouling‑resistant membranes. Another case cited by EAI Water shows that removing hardness upstream cut fouling by about half and extended membrane life. In a home setting, the rough equivalents are investing in good sediment and carbon pre‑filters, using a softener on very hard water, and following manufacturer recommendations about chlorine protection and antiscalant use where applicable.

Viewed through this lens, optimizing cleaning frequency is not only about the calendar. It is about using better pretreatment and gentler, timely cleaning so that you spend less time fighting hard‑to‑remove fouling and more time simply maintaining a stable baseline.

How Water Quality and System Design Shift the Ideal Cleaning Interval

Not all RO systems live the same life. Well water in a rural area, chlorinated city water in an older urban neighborhood, and an industrial UPW system all place different stresses on their membranes. The sources in our research paint a consistent picture of how those differences play out.

Angel Water highlights that well water can contain iron bacteria, coliform bacteria, and other microorganisms that demand thorough pretreatment and regular maintenance. The same provider notes that city water in many regions can carry lead and chromium‑6, making reliable RO performance a health issue rather than just a taste concern.

Alamo Water Softeners explains that pairing your RO with a softener lowers hardness‑related stress on the membrane. With softened water, they are comfortable recommending longer intervals between filter changes and membrane replacement. Without softening, they see more rapid fouling and advise more frequent service.

University of Nebraska Extension points out that feed‑water temperature influences RO output significantly. They report that for each degree Fahrenheit below about 77°F, treated water production typically drops by around 1 to 2 percent. That means a system fed with cold well water near 45°F may produce only about half as much water as the same system at 77°F. Colder water will feel like a sluggish system even when the membrane is clean, so you have to distinguish between seasonal temperature effects and true fouling.

Industrial guidance from DuPont and Kurita America adds that target recovery rate and system configuration also matter. Systems designed to push recovery very high tend to foul faster and need more frequent cleaning than those that operate at more modest recovery.

Pulling from these sources, you can think about your situation in broad categories:

If you are on hard well water without softening, expect shorter cleaning intervals and a stronger emphasis on pretreatment, including iron and hardness control, plus careful disinfection.

If you are on chlorinated city water with moderate hardness and a pre‑installed softener, you can usually lean toward the longer end of the cleaning frequency range, while still sanitizing annually and watching performance metrics.

If you operate a high‑demand or small commercial system (for example, a coffee shop, juice bar, or small lab), your calendar interval will shrink simply because you are using the membrane more hours per day. In that case, performance‑based triggers are even more important than the calendar itself.

A Practical Monitoring Routine for Smart Home Hydration

Home RO systems do not come with a plant control room, but you can still apply the same philosophy: watch the right indicators, at the right intervals, and let them guide your cleaning decisions.

Residential providers like Crystal Quest, Culligan, Nu Aqua, and Frizzlife all converge on a few simple habits.

Make taste, odor, and flow part of your normal awareness. When water begins to taste slightly chlorine‑like or metallic, or when a faint “flat” or musty note appears, it is often your first early warning that carbon filters or the membrane are losing effectiveness. Angel Water and CalSoft both flag bad taste and odor as key signs that an RO system needs service. Similarly, a noticeable drop in faucet flow or a system that runs almost constantly to fill the tank points toward clogged pre‑filters or a fouled membrane.

Use a TDS meter as a quick health check. Crystal Quest suggests that a properly functioning RO system reduces TDS to well under 50 ppm in many city water situations and that the important metric is relative reduction: roughly 90% lower TDS than the feed. For example, if your tap water is 300 ppm and your RO water is 20 to 30 ppm, you are in good shape. If, over time, the RO reading drifts into the 60 to 80 ppm range with the same feed water, you are likely crossing into “time to clean or replace” territory.

Do a simple flow test a couple of times per year. Choose a standard glass or container and record how long it takes your RO faucet to fill it when the system is freshly serviced. If six months later that fill time has stretched by 20% or more under similar conditions, you have a concrete sign that fouling is affecting permeability.

Keep a written or digital log. Frizzlife recommends maintaining a maintenance log and notes that professional servicing typically costs about $100 to $200. A simple spreadsheet or note on your phone that tracks filter changes, sanitization dates, TDS readings, and observations about taste and flow will quickly show whether your current cleaning frequency is keeping performance stable or chasing a decline.

Once you have a year or two of data, cleaning frequency ceases to be a guess. You will see, for your specific water and usage, about how many months it takes for flow or TDS reduction to drift outside your comfort zone. That history is far more powerful than trying to copy a generic schedule from a manual.

What Industrial RO Can Teach Homeowners About Smart Cleaning

You might wonder what a steel plant or an ultrapure‑water facility has to do with a small under‑sink RO system. Quite a lot, as it turns out, once you strip down to the core principles.

Kurita America and DuPont describe membrane CIP as a normalized, data‑driven process. They recommend cleaning when key indicators hit specific thresholds, not “whenever someone remembers.” They design cleaning sequences with a pre‑rinse, low‑pH clean, high‑pH clean, and careful rinses in between, always respecting the membrane manufacturer’s pH and temperature limits. Plants that implement this kind of disciplined strategy see longer membrane life and fewer unplanned shutdowns.

DuPont reports a case in which a steel facility struggling with biological fouling upgraded to fouling‑resistant membranes. Before the change, cleanings were required about every 22 days on average. After the change, the interval stretched to around 52 days, more than doubling uptime between cleanings. That improvement did not come from cleaning “harder,” but from combining better membrane selection with the same kind of performance monitoring and cleaning triggers discussed earlier.

On the research front, a study highlighted in the Journal of Membrane Science and summarized through ScienceDirect used several years of real plant data and advanced forecasting models to explore how different cleaning‑in‑place trigger pressures affected operating cost and membrane life. The core insight is that there really is an optimum: clean too early and you waste chemicals and downtime; clean too late and you suffer higher energy usage and irreversible damage. The sweet spot depends on your system and your economics.

Bringing this back to your kitchen, you obviously will not run neural networks on your RO data. But the pattern holds. If you pay close attention to when performance begins to drift, and you respond with timely, method‑appropriate cleaning and good pretreatment, you will land in your own optimal band: enough cleaning to protect water quality and membrane life, but not so much harsh chemical exposure that you shorten the membrane’s useful years.

Short FAQ

How do I decide between cleaning and replacing my RO membrane?

Several residential guides, including those from Crystal Quest and Angel Water, suggest using both age and performance. If your membrane is under about 2 to 3 years old and performance has slipped modestly, a proper chemical cleaning can often restore flow and TDS reduction. If the membrane is older than roughly 3 to 4 years, heavily fouled, or shows poor rejection even after cleaning, replacement is usually more cost‑effective. Industrial and community experts also note that once normalized performance has fallen 30 to 50% below baseline, cleaning may never fully recover it, which is another strong signal that replacement should be on the table.

Is it safe to clean a home RO membrane myself?

Many tasks, like basic filter changes, tank sanitization, and even membrane removal and soaking, are considered DIY‑friendly by manufacturers such as Crystal Quest and Aqua‑Wise. They provide detailed instructions that emphasize gloves, eye protection, staying within approved temperature and pressure limits, and thorough flushing afterward. However, if you are dealing with heavy fouling, complex multi‑stage systems, or if you are not comfortable handling high‑ or low‑pH cleaners, it is wise to bring in a water treatment professional. Several sources, including Frizzlife and Culligan, point out that periodic professional service every few years can catch issues early and ensure that all components are functioning correctly.

Can better pretreatment really reduce how often I have to clean the membrane?

Yes. EAI Water describes an industrial case where adding hardness removal upstream cut membrane fouling by about half. Chunku and Kurita America stress that good pretreatment, including sediment filtration, carbon for dechlorination, and appropriate antiscalant dosing, can significantly reduce the fouling rate and cleaning frequency, sometimes effectively doubling membrane service life. At home, the equivalent is making sure your sediment and carbon pre‑filters are replaced on schedule, considering a water softener if your water is very hard, and following manufacturer recommendations for protecting thin‑film membranes from chlorine. The less punishment you feed into the membrane, the less often you will need to clean it.

Staying well‑hydrated should not require a chemistry degree, but the water that supports your health does deserve thoughtful care. When you pair simple, regular monitoring with evidence‑based cleaning thresholds and solid pretreatment, your RO membrane becomes a long‑lasting, efficient partner in your home hydration routine instead of a silent question mark under the sink.

References

- https://open.clemson.edu/cgi/viewcontent.cgi?article=1009&context=envengineering_pres

- https://news.mit.edu/2021/using-mechanics-cleaner-membranes-0510

- https://commons.und.edu/cgi/viewcontent.cgi?article=2858&context=theses

- https://extensionpublications.unl.edu/assets/html/g1490/build/g1490.htm

- https://digitalcommons.usu.edu/context/water_rep/article/1504/viewcontent/Reverse_20Osmosis_20in_20the_20Treatment_20of_20Drinking_20Water.pdf

- https://www.alamowatersofteners.com/your-guide-to-maintaining-your-reverse-osmosis-system/

- https://www.aqua-wise.com/post/easy-diy-tips-for-cleaning-reverse-osmosis-membrane

- https://chunkewatertreatment.com/ro-membrane-cleaning-techniques/

- https://complete-water.com/resources/cleaning-ro-membranes

- https://www.culligan.com/blog/how-to-keep-your-water-filtration-system-working-properly

Share:

Understanding How to Assess the Lifespan of RO Membranes

Understanding Common Issues After Replacing Water Filters