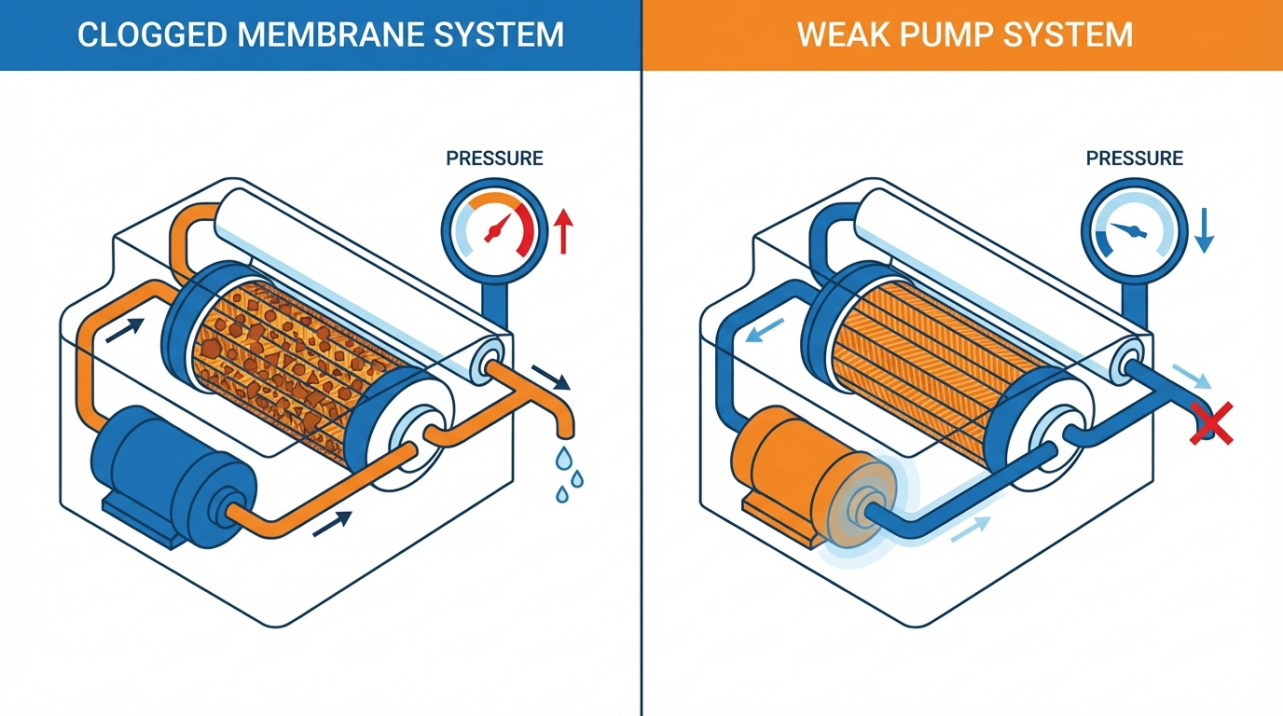

Summary: Membrane blockage makes your system work hard but produce little, while insufficient pump pressure means the system never gets the push it needs; watching how pressure, flow, and water quality change over time tells you which one you’re dealing with.

How Healthy Pressure-Driven Filtration Is Supposed to Work

In most under-sink RO and whole-home filtration setups, a pump pushes water through pre-filters and then across a tight membrane that screens out salts and contaminants.

For the system to hydrate your home properly, you need two things at the same time: a clean membrane surface and enough incoming pressure (often 40–60 psi for residential RO).

When either piece fails, you feel it at the faucet as slower fill times, weak shower pressure, or water that just doesn’t taste as crisp.

What Membrane Blockage Looks and Feels Like

Membrane “blockage” is really fouling and scaling: layers of fine sediment, minerals, and biofilm clog the membrane surface and pores. Reviews from AXEON, Kurita America, and MDPI’s Water journal all show the same pattern in pressure-driven systems.

Typical signs of membrane blockage:

- The pump still builds pressure, sometimes even higher than normal, but clean-water flow steadily declines.

- You see a clear 10–20% drop in production over weeks or months, not overnight.

- Differential pressure (the pressure drop from inlet to outlet of the membrane housing) rises.

- TDS in the product water slowly creeps up, or taste and odor deteriorate.

Because the pump is pushing against a plugged surface, energy use goes up, components run hotter, and you may hear more strain or vibration even though little water is coming out.

What Insufficient Pump Pressure Looks Like

Insufficient pump pressure is a hydraulic supply problem, not a membrane problem. The booster pump or city line simply never delivers enough push for the membrane to work at its design point.

Common signs of low pump pressure, drawn from booster-pump guidance and residential RO field data:

- Flow is weak everywhere downstream, including at an unfiltered tap tied to the same line.

- System pressure never reaches the normal setpoint (often below 40 psi at the RO inlet).

- Water quality (TDS) may still be acceptable, just at a much lower production rate.

- The pump may short-cycle, run noisily, or fail to start because flow/pressure switches never stabilize.

In this case, the membrane can be perfectly clean; it just doesn’t see enough pressure to push water through at a healthy rate.

Simple At-Home Checks to Tell Them Apart

You don’t need lab gear to separate a blocked membrane from a weak pump. Start with these quick checks:

- Measure inlet pressure: Check the pressure gauge before the membrane while the system is running; if it cannot reach your system’s recommended minimum (often around 40–60 psi), suspect the pump or supply.

- Compare feed vs. product TDS: If TDS rejection is still high (for example, feed at 300 ppm and product around 10–30 ppm) but flow is low, pressure is more likely the issue; if rejection is poor and pressure looks normal, the membrane is likely fouled or damaged.

- Bypass or replace pre-filters briefly: If temporarily installing fresh sediment and carbon filters restores pressure and flow, the “blockage” may be in pre-filters, not the membrane or pump.

- Listen to the pump: A pump running constantly at high load with strong inlet pressure but weak product flow points toward membrane blockage; a pump that can’t ramp up or keeps cycling on and off points to pressure or control issues.

If you’re unsure, a hydration-focused water pro can log pressure, flow, and TDS over time and interpret the patterns for you.

Fixing the Root Cause for Better Everyday Hydration

When blockage is the culprit, the long-term fix is cleaner feed water plus appropriate membrane maintenance. That usually means: high-quality sediment and carbon pre-filters, softened water where hardness is high, occasional chemical cleaning in larger systems, and membrane replacement every 2–3 years in typical homes, as noted by several RO manufacturers.

When low pump pressure is the culprit, focus on the hydraulics instead: right-size or add a booster pump, use flexible connectors and a proper bypass line, and check for leaks or partially closed valves that bleed off pressure before the membrane.

From a health and hydration standpoint, both issues matter. A blocked membrane can let more contaminants sneak through, while a chronically under-pressured system simply won’t make enough high-quality water—pushing you back to bottled water or less drinking overall.

Diagnose accurately once, fix the true bottleneck, and your filtration system can quietly support better hydration for years instead of fighting the same symptoms over and over.

References

- https://pmc.ncbi.nlm.nih.gov/articles/PMC10102236/

- https://www.tceq.texas.gov/downloads/drinking-water/plan-technical-review/forms/membrane-common-issues.pdf

- https://pubs.acs.org/doi/10.1021/ie402056r

- https://www.aqualitek.com/best-ways-to-identify-ro-membrane-fouling-or-scaling-at-an-early-stage-insights-by-aqualitek.html

- https://www.bokawater.com/info-detail/how-to-tell-if-ro-membrane-is-bad-6-obvious-signs

Share:

Understanding Why Your RO System Trips on Startup Moments

Strategies for Calibrating Drift in Smart Sensors Effectively in Home Water Systems