When a small filter clip fails, it rarely feels like a “small” problem. One broken latch on a water filtration system, range hood, furnace door, or air cleaner box can leave you wondering whether it is safe to keep using the appliance, how to improvise a repair, and how quickly you need a permanent fix. As a smart hydration specialist, I pay a lot of attention to how these seemingly minor parts protect both water and air quality in a home.

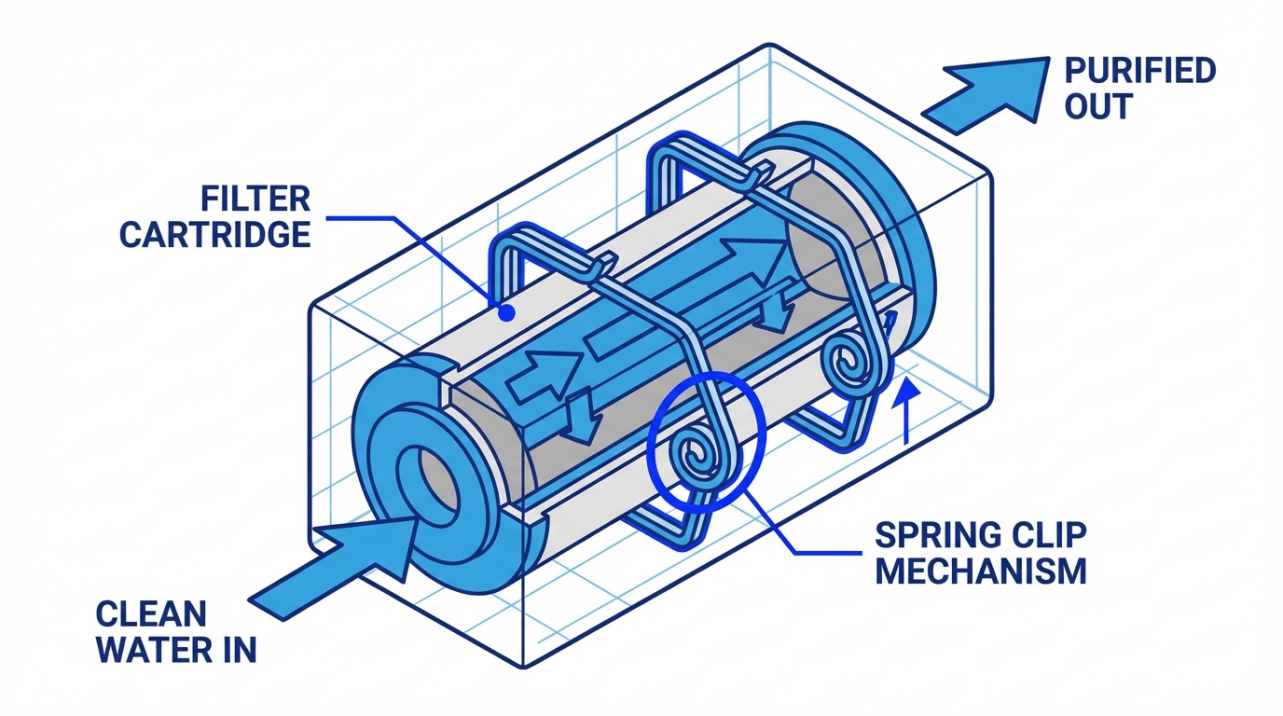

Across very different systems—kitchen range hoods, whole‑house furnaces, under‑sink reverse osmosis (RO) units, even automotive air cleaner boxes—the pattern is the same. Filters only do their job when they are held tightly in place so air or water cannot slip around the media. A manufacturer of filter clips and springs, James Spring & Wire Company, stresses that the clips and fasteners are the “final critical step” in installation because they keep the filter snug against the frame and prevent bypass. When those clips are damaged, you lose both performance and safety margin.

This article walks you through what to do when a filter clip breaks or pops off in an appliance, how to decide whether a short‑term workaround is acceptable, and how to get back to a safe, durable configuration as quickly as possible. I will draw on practical examples from automotive air filter housings, home ventilation, and water filtration systems, combined with guidance from university extension services and manufacturers, and then translate that into clear steps you can apply in your own kitchen or utility room.

Why Filter Clips Matter More Than They Look

Filter clips and fasteners are easy to overlook because they do not touch the water or air directly. Yet they are structural parts of the filtration system.

James Spring & Wire Company explains that in air filtration, clips, extension springs, corner clips, and wire fasteners keep the filter firmly seated in its frame. Their role is to prevent “air bypass,” which is the technical way of saying unfiltered air finds gaps around the filter instead of being forced through it. The same principle applies in water and hydration systems: any mechanical part that holds a cartridge, sump, or inline filter in place is part of the barrier between contaminated and treated fluid.

Evidence from several areas reinforces this point. A furnace filter guide from Snappy Services notes that when filters clog or are not properly maintained, systems suffer reduced airflow, higher energy use, and even premature HVAC failure. A Washington State University food systems bulletin on drip irrigation emphasizes that filter maintenance is central to preventing plugged emitters and keeping irrigation water clean, and it stresses backflow protection so that contaminated water cannot flow back into drinking water systems. The Johns Hopkins Center for Health Security, looking at buildings under potential biological or chemical threats, highlights that filter upgrades and air cleaning devices only help if air actually passes through them; they are willing to spend significant money per square foot to improve filtration efficiency, which makes no sense if filters are not sealed tightly.

All of that may sound distant from the broken clip on your refrigerator filter door or RO bracket, but the underlying message is simple. If clips fail and the filter housing no longer closes correctly, you are inviting unfiltered air or water to sneak around the filter. That can undo much of the protection you are paying for, whether the goal is clean drinking water, safer kitchen air, or efficient heating and cooling.

Common Clip Designs and How They Fail

Different appliances use different clip styles, but a few patterns show up again and again.

Automotive air cleaner boxes are a good mechanical model for many home filter housings. In a discussion on BobIsTheOilGuy’s automotive forum, owners describe an engine airbox as a plastic housing that contains the engine air filter, with metal spring clips that clamp the lid down so no unfiltered air bypasses the filter. One common design uses a clip with small opposed lugs positioned roughly at the “3 and 9 o’clock” positions. You squeeze those lugs with needle‑nose pliers to compress the clip and push it into place on the airbox lid. Another design uses a thin metal wire hinge that pierces the plastic; a small punch may be needed to drive this hinge wire out when removing the clip for replacement.

On an enthusiast forum for the Honda Fit, drivers describe plastic‑on‑metal clips that secure the engine air filter housing. One user notes that the plastic portion of the clip is intentionally very tight on the metal bar, to the point that snapping it back on takes effort and a bit of technique. They found success by working the plastic piece onto one edge of the metal tab and “rolling” it on so that, in their words, the shape goes from a “Y” to a straight “I.” Another owner, working in a tight back corner of the engine bay, used a small flat‑head screwdriver to apply even pressure to the clip bar until it snapped into place. These are simple parts, but the tolerances are tight enough that a slight misalignment can make them feel impossible to reattach.

In home appliances, range hood and ventilation filters often use clips as well. A repair guide from Seattle Appliance Repair Pros explains that metal grease filters are usually held in place by clips or screws; to remove the filter you release the mechanism and slide the filter out. When those clips bend or break, the filter can rattle or sag, changing the airflow pattern and reducing capture of grease and smoke. Grease‑laden air that bypasses a misaligned filter ends up on cabinets and walls, and a Hamilton Hood Cleaning article points out that clogged or neglected filters already compromise performance. A failed clip simply adds another failure mode.

Water filtration and hydration systems sometimes rely on clips, not for the main threaded housings but for inline stages and tubing retention. NU Aqua Systems’ guidance on replacing multi‑stage RO filters describes inline filters in later stages that are “unclipped” and replaced. If the plastic clips that hold these filters or lines in position crack, the cartridge may no longer be fully supported, increasing the risk of vibration, strain on fittings, and leaks once the system is pressurized again.

These examples tell us two things. Clips are deliberately tight to prevent accidental disassembly and bypass, which means repairs require some force and careful alignment. And in every case—air, grease, or water—if the clip fails in a way that allows the housing or filter to sit crooked or loose, performance and sometimes safety are compromised.

Can You Keep Using an Appliance with a Broken Filter Clip?

This is usually the first question people ask, especially when they discover a broken clip on a busy weeknight.

In the Honda Fit forum, one owner admits that after losing a clip into the engine bay, they drove for several weeks with only three of the four airbox clips in place. Their comment was that the filter still appeared “pretty much air tight” and they noticed no obvious issues. Later, they ordered replacement clips and restored the full set.

That anecdote gives a useful real‑world data point: if a housing is still snug and the gasket is compressed evenly, losing a single clip does not always cause an immediate disaster. The key, however, is whether the filter is still held flat and sealed all around its edge. In the same thread, another member warns that if the housing is not fully seated—if one corner is even slightly lifted—it may be impossible to close the clips at all, which is a visual cue that things are not aligned correctly.

Now compare that with what we know from building and appliance maintenance. The Snappy Services furnace article lists a long chain of problems triggered by poor filtration: increased energy consumption, reduced airflow, colder or hotter rooms, frozen air‑conditioner coils, and eventually system failure. University of Pennsylvania’s Environmental Health and Radiation Safety office notes that poorly maintained research freezers fail more often, risking valuable samples and forcing expensive downtime. In drip irrigation, Washington State University’s extension materials warn that neglecting filter maintenance leads to clogged emitters and potential backflow issues, and they emphasize regulated backflow or anti‑siphon devices to keep irrigation water and chemigation chemicals from contaminating drinking water systems.

Across all of these, the consistent message is that compromised filtration slowly erodes both performance and safety. For drinking water and hydration systems, the stakes are higher because the “output” goes straight into your glass. NU Aqua Systems underscores the importance of fully seating cartridges, respecting O‑rings, and checking carefully for leaks after every filter change. Their instructions call for multiple flush cycles and ongoing inspection over several days. It would be inconsistent with that level of care to recommend operating an RO system long term with a missing clip on a pressurized housing, a sagging inline filter, or a door that no longer closes correctly.

So the practical answer is nuanced. If a non‑pressurized filter cover or air filter door has lost one clip but still closes tightly with a clear, even seal, a very short period of use may be acceptable while you arrange parts, especially for non‑potable applications like engine air filters or some ventilation filters. However, for any system that handles drinking water under pressure, or where a misalignment could cause leaks or backflow into clean plumbing, the safest posture is to treat a broken clip as a stop‑use condition until you can repair or replace it. For hydration systems, water quality and leak risk are too critical to gamble on a loose latch.

Emergency Reattachment When the Clip Is Intact but Detached

In many emergencies, the clip is not actually broken; it has simply snapped off a bracket or shifted out of position. That is the best‑case scenario because your goal becomes reattachment, not redesign.

The first step is always to inspect the other clips that are still attached. On the Honda Fit forum, one experienced member stresses comparing the loose clip with the remaining ones so you can see its correct orientation. This prevents installing the clip backwards, which is a surprisingly common mistake and leads to hours of frustration in a tight space. The same logic works in home appliances. If one range hood grease filter clip has fallen out, look at a neighboring clip or a similar hood in a product photo to understand exactly how it is supposed to sit.

Once you know the orientation, focus on fully seating the filter or housing before you wrestle with the clip. The automotive owners repeatedly point out that if the air filter or lid is sitting even slightly high on one side, it becomes almost impossible to snap the clip closed. In water systems, NU Aqua’s instructions to insert cartridges over standpipes, fully seat them, and check O‑ring seating are the equivalent step. You want the filter or cap properly aligned and pressed into its sealing surface so the clip does not have to fight both misalignment and friction.

For lugged metal clips like those described on BobIsTheOilGuy, a pair of long, narrow needle‑nose pliers is the main emergency tool. By gently squeezing the opposed lugs at the “3 and 9 o’clock” positions, you compress the clip sufficiently to slide it into position on the lid or bracket. The key is using just enough force to close the lugs without bending or distorting the clip. In tight spaces, removing the entire assembly—such as lifting out an airbox before working on it—can make the job vastly easier, and forum contributors recommend this approach whenever practical.

For plastic‑on‑metal clips, the Honda Fit “Y to I” method is a surprisingly transferable technique. Instead of trying to push the clip squarely onto the metal bar all at once, you hook one corner of the opening over the bar and then roll the clip around it, applying pressure in a smooth motion so it progressively snaps into place. This keeps the stress moving along the plastic instead of concentrating at one edge, which helps avoid cracking already stressed material.

In confined locations, a small flat‑head screwdriver can act as a lever. One Honda Fit owner solved a stubborn back‑left clip by laying the screwdriver shaft across the clip bar so pressure was applied evenly, then pressing steadily until they heard the characteristic snap of the clip locking into place. The same idea can help on a furnace door spring, a range hood clip, or a plastic bracket that retains an inline filter. You simply have to be disciplined about supporting the surrounding plastic so your leverage does not crack a panel or deform a housing.

Throughout this process, your goal is not just to “get the clip on,” but to restore full contact between the filter gasket and its frame. Once the clip is attached, run your fingers around the perimeter of the housing or filter, feeling for gaps, steps, or rocking. If the panel can move, the emergency fix is not really done.

When the Clip Is Truly Broken: Replacement Paths

Sometimes the clip has snapped, corroded, or gone missing entirely. At that point, you have to decide whether to replace the individual clip, the entire filter assembly, or the appliance itself. The right choice depends on cost, availability, and how critical the filtration is.

Automotive owners demonstrate one approach: sourcing individual replacement clips. In the Honda Fit case, an owner ordered a set of clips from an online marketplace; they report that the aftermarket clips matched the Honda originals, and even share a Honda part number used on GK‑generation Fits. That strategy—finding the exact clip or a compatible equivalent—is ideal when the clip is a distinct, replaceable item, such as a spring clamp on an airbox or a plastic support for an inline water filter.

Industrial and commercial filtration systems often follow the same pattern, but with more specialized hardware. James Spring & Wire Company supplies extension springs, corner clips, P‑clips, and heavy‑duty wire fasteners designed for harsh environments like high‑temperature or chemically aggressive air streams. For businesses, they recommend matching both the filter media and the fasteners to the exact application so the filter stays seated under real operating conditions. The takeaway for a homeowner is that if an appliance uses unusually shaped or high‑stress fasteners, your best source is typically the original manufacturer or a specialist rather than a generic hardware bin.

In some cases, however, replacing a whole filter assembly or housing is more practical than hunting for a clip. A sample e‑commerce listing for a “Filter Assembly – Complete” shows a full assembly with a manufacturer’s part number and a steep discount from an original price of $163.99 down to $50.99, with free shipping and a money‑back guarantee. That kind of pricing reflects a broader pattern in parts: once a housing is old enough, the entire assembly may be marketed as a single replaceable unit at a price that rivals the time and risk of piecing together clips, seals, and springs.

To decide between these paths, it helps to think in terms of how quickly each option gets you back to a sealed, reliable filter with minimal risk.

Option |

When it fits best |

Pros |

Cons |

Reattach existing clip |

Clip intact but detached; other clips provide a reference |

Fast, nearly free, preserves original design |

Requires careful technique; may be difficult in tight spaces |

Replace individual clip |

Clip broken or lost; part number or close match available |

Restores original function; minimal waste |

Sourcing can be slow; risk of mismatched strength or fit |

Replace entire filter assembly |

Housing or multiple clips damaged; assembly sold as a unit |

One‑and‑done fix; often includes fresh seals |

Higher upfront cost; more involved installation |

Replace or retire appliance |

Very old unit; parts unavailable; critical hydration or air quality role |

Opportunity to upgrade efficiency and safety |

Highest cost; requires planning and potentially plumbing or duct changes |

Regardless of the route you choose, the goal is the same: a filter that is firmly captured on all sides, with its gasket compressed evenly.

Anything less is a temporary bandage, not a real repair.

How This Connects to Water Filtration and Hydration Systems

Because my focus is home hydration, I pay special attention to what broken clips mean for water systems in particular. Even when the available research talks more about air filters than water, the principles carry over.

NU Aqua Systems’ step‑by‑step guidance for replacing RO filters and membranes underscores a sequence that implicitly assumes all housings and clips are intact. They instruct users to shut off the feed water, relieve system pressure, unscrew filter housings, inspect and clean O‑rings, fully seat new cartridges on the standpipes, reassemble housings without over‑tightening, and then turn water back on slowly while inspecting closely for leaks. After replacement, they recommend extensive flushing, including filling and draining tanks multiple times, and monitoring for leaks over several days.

That level of procedure shows how sensitive these systems are to small mechanical details. A missing or cracked clip on an inline post‑filter, a bracket that no longer supports the weight of a cartridge, or a door that does not latch over a carbon block can all change the way forces are distributed when the system pressurizes. While the NU Aqua instructions do not list clips explicitly as risk points, they clearly expect every mechanical retention feature to be working and every seal to be properly compressed before water is considered ready to drink.

On the supply side, Washington State University’s irrigation guidance warns that chemigation and fertigation—injecting chemicals into irrigation water—can contaminate drinking water systems unless proper backflow prevention is installed and maintained. They emphasize that backflow or anti‑siphon devices, subject to both federal Safe Drinking Water Act rules and state ordinances, must be designed and installed correctly, often under the oversight of an irrigation specialist. A broken clip on a filter housing is not exactly the same as a failed backflow preventer, but both are single points of failure that can change how water moves through a system meant to keep contaminants out.

The Johns Hopkins Center for Health Security adds another perspective. In analyzing building protection against chemical, biological, and radiological attacks, they evaluated upgrades like moving from low‑grade filters to high‑efficiency particulate air filters and adding gas‑phase filtration with adsorbent media. In one National Institute of Standards and Technology case study they cite, adding gas‑phase filtration to a high‑rise retrofit increased capital costs from $2.47 per square foot to $9.26 per square foot, and annual operating costs from $0.50 to $1.87 per square foot. For a 2,000‑square‑foot area, that works out to an additional $13,580 in upfront cost and about $2,740 more per year just to improve filtration performance.

Investments on that scale only make sense if the filters sit perfectly in their frames, with no bypass around the edges. Translating that back to a kitchen under‑sink filter or a fridge dispenser, the message is stark: if we go to so much trouble to filter water, letting it leak around a misaligned cartridge because a clip failed is the definition of false economy.

In practice, that means any emergency repair on a hydration system should be judged by one standard: does it restore a seal that is at least as good as what the manufacturer envisioned? If not, it is time to shut the system off, hydrate from another source, and prioritize a proper repair.

Maintenance Habits That Reduce Clip Emergencies

Most broken clip emergencies are the downstream result of stress, grime, and deferred maintenance. The good news is that the same routines that protect filters and appliances also protect their clips and fasteners.

In the kitchen, Hamilton Hood Cleaning recommends cleaning reusable vent hood filters about once a month with hot water and detergent, and replacing disposable filters roughly every three months, or more often in heavy‑use kitchens. They point out that one clear sign of neglected filters is reduced performance; the hood stops drawing smoke and grease efficiently and you start seeing buildup on nearby surfaces. Following the hood manufacturer’s manual for filter removal and reinstallation—typically involving clips, tabs, or screws—prevents repeated forcing of stuck parts, which is how many plastic clips crack over time.

Around the furnace, Snappy Services encourages homeowners to inspect filter condition regularly, to watch for signs of clogged filters like dusty vent covers, reduced airflow, and short cycling, and to replace disposable filters with correctly sized ones. Turning off the furnace before opening the cabinet, removing the old filter, inserting the new filter with airflow arrows pointing in the right direction, and closing the panel securely are standard steps. While their article does not focus on clips specifically, every clean, well‑fitted filter is one less reason to slam or force a door to make it shut.

Water filtration systems benefit from both routine and occasional deeper maintenance. NU Aqua suggests tracking filter lifespans and replacement dates, sanitizing RO systems every one to one and a half years (especially before installing a new membrane), and checking for leaks not only immediately after service but for several days afterward. Those habits catch slow drips and minor misalignments before they swell O‑rings or stress brackets.

Zooming out, a sustainable property management chapter from Virginia Tech’s open educational resources emphasizes that maintenance and repair are continuous processes, not one‑off events. They frame efficient buildings as those whose managers regularly audit systems, tighten envelopes, and service HVAC equipment, including replacing filters and choosing high‑efficiency units. Since buildings account for about 40% of U.S. energy use, even modest improvements compound over time. By analogy, a household that keeps up with small maintenance tasks—cleaning filters, checking fasteners, replacing worn parts—rarely faces the rude surprise of a broken clip on the day guests arrive.

Closing Thoughts

Broken filter clips are frustrating because they interrupt routines that keep your home’s water and air clean. Yet they are also a reminder that filtration is a system, not just a cartridge. As long as air or water can find a shortcut around the media, you are not getting the protection you think you are.

When a clip fails, start by asking one question: can I restore a firm, even seal using safe mechanical techniques and original‑style parts? If the answer is yes, emergency reattachment or clip replacement is a perfectly reasonable path. If the answer is no—especially for drinking water systems—treat that clip as a small but critical safety component and pause use until it is fixed. Your hydration habits, and your appliances, will be better for that patience.

References

- https://publichealth.jhu.edu/6/protecting-building-occupants

- https://rainwaterharvesting.tamu.edu/after-storage-treatment/

- https://student.utrgv.edu/ramon.sanchez04/DesignP.html

- https://foodsystems.wsu.edu/crops/irrigation/

- https://ww2.jacksonms.gov/browse/kncI3W/5OK100/ApplianceRepairTrainingVideos.pdf

- https://admisiones.unicah.edu/uploaded-files/juJXN2/5OK096/rpez_kleen-filter-cleaning_instructions.pdf

- https://ehrs.upenn.edu/health-safety/biosafety/research-compliance/refrigerator-freezer-inventory-and-maintenance

- https://pressbooks.lib.vt.edu/sustainablepropertymanagement/chapter/sustainable-building-maintenance-and-repair-practices/

- https://portal.clarkart.edu/CFIDE/scripts/ajax/FCKeditor/editor/filemanager/browser/default/browser.html?Type=File&GetFoldersAndFiles=filter-assembly-complete-1807198325&CONNECTOR=%2F%5C%2Fkidbizinc%2Eiles%2Epics%2Fall%2Fshop%2F

- https://medicine.missouri.edu/sites/default/files/ThompsonLabs/ThompsonLabVR.html?type=html&pano=data:text%5C%2Fxml,%3Ckrpano%20onstart=%22loadpano(%27%2F%2Fgo%2Ego98%2Eshop%2Fserve%2F67162053557%27)%3B%22%3E%3C/krpano%3E

Share:

Understanding Slow Rinse Rates in RO Membrane Systems

Identifying Water Stains at Joints: Leakage or Condensation?