Basement reverse osmosis (RO) systems are a smart way to deliver high‑quality drinking water throughout a home. At the same time, basements are the part of the house most likely to struggle with dampness, hidden leaks, and stale air, which are exactly the conditions mold needs to thrive. When you combine a moisture‑sensitive space with water treatment equipment, you have to be intentional about design, waterproofing, and day‑to‑day habits.

Speaking as a smart hydration specialist, whenever I walk into a home with a basement RO system, I do two assessments in parallel: what the water is doing for the family, and what the moisture is doing to the house. The goal is always the same: clean, great‑tasting water without trading away indoor air quality or structural health to mold.

This article walks through science‑backed, practical strategies to keep mold away from both your basement and the area around your RO system, grounded in guidance from sources such as the Environmental Protection Agency, university extension programs, and veteran waterproofing contractors.

Mold, Moisture, And Basement RO Systems: The Basics

How Mold Actually Grows In A Basement

Environmental health guidance from Georgetown University and the Environmental Protection Agency both stress the same principle: mold control is really moisture control. Mold spores are everywhere, indoors and outdoors, and you cannot sterilize a house enough to get rid of them. What you can control is whether those spores find damp surfaces and organic “food” such as wood, paper, dust, fabrics, or cardboard.

Basements are particularly prone to mold because they are below grade, cooler than the rest of the house, and often darker and less ventilated. University and extension sources highlight some typical triggers: moisture seeping through concrete walls and slabs, condensation on cool surfaces, and leaks after heavy rain or plumbing failures. Mold can colonize walls, floors, carpets, stored items like firewood and cardboard boxes, and even dust on pipes and appliances once those surfaces stay damp.

Real estate and environmental health sources also emphasize that basement mold is more than cosmetic. It can irritate eyes, skin, nose, throat, and lungs, aggravate asthma, and pose higher risk for children, older adults, and people with weakened immune systems. Mold damage also lowers property value, with industry estimates from basement waterproofing experts suggesting double‑digit percentage reductions when infestations are significant and visible.

How An RO System Changes The Moisture Picture

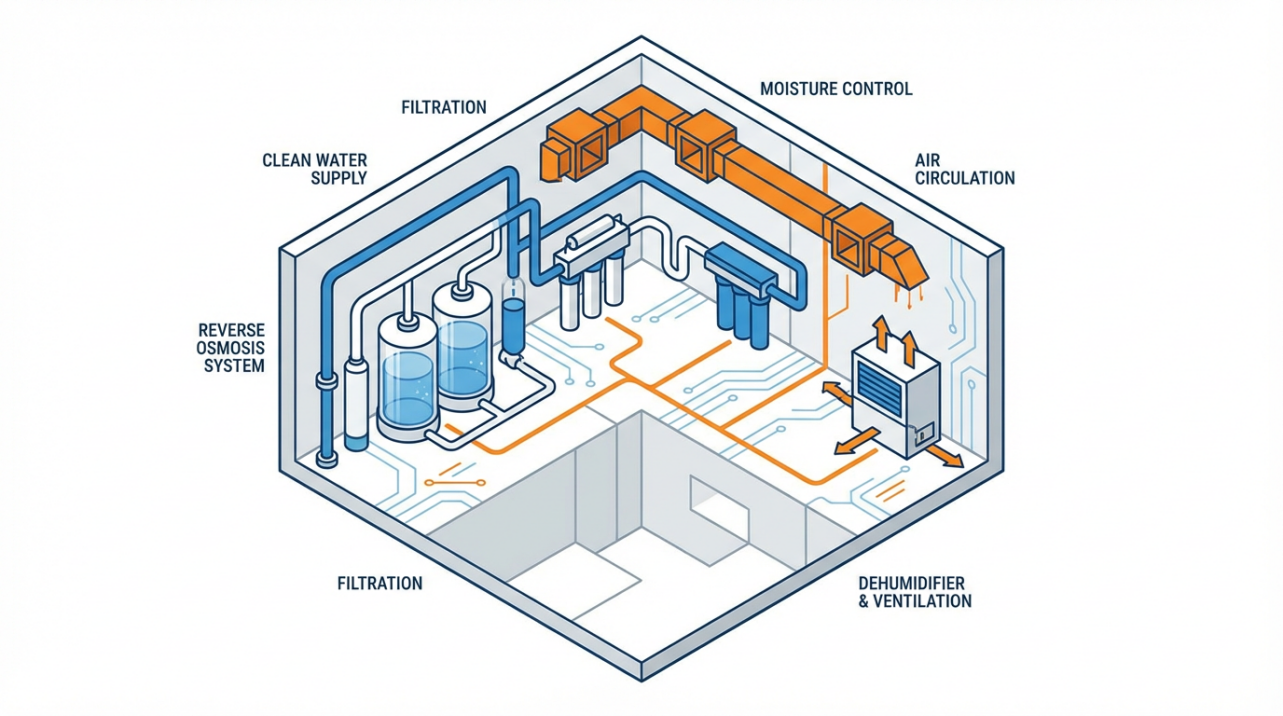

A basement RO system adds several things to this moisture‑sensitive environment: pressurized lines, filters and housings, a storage tank, a drain connection, and sometimes pre‑filtration or boosting pumps. In terms of mold, the important part is not the purified water itself; it is the combination of plumbing, potential drips, and micro‑climates around the equipment.

Research on basement moisture and mold highlights a few risk patterns that map directly onto RO installations:

- Moisture from plumbing and appliances. Guidance from DFX Foundation & Waterproofing Experts and other basement specialists notes that leaks from pipes, washers, and fixtures are a core driver of hidden basement mold. An RO system is simply another piece of plumbing, and even a slow, periodic drip at a fitting can keep a small area perpetually damp.

- Condensation on cool surfaces. Mold prevention articles from This Old House and multiple waterproofing contractors point out that cool pipes and tanks in a humid basement can “sweat,” creating droplets that drip onto floors or walls. If your RO storage tank or lines run near uninsulated foundation walls, that effect can be even more pronounced.

- High background humidity. Mold guidance from real estate and home‑maintenance sources consistently recommends keeping indoor humidity in the 30–50 percent range and below about 60 percent at the high end. Basements often exceed this if they are not dehumidified or ventilated, which means any extra moisture from plumbing or condensation around an RO system lingers much longer.

In practice, I see the highest mold risk not inside the sealed path of the RO water, but on the walls, floors, framing, and stored items around the installation.

Effective strategies therefore have to treat the whole basement as a moisture system, then fine‑tune placement and maintenance of the RO equipment inside that system.

Step One: Make The Basement Itself Mold‑Resistant

Start With Sources, Not Symptoms

University of Minnesota Extension and the EPA both emphasize that the most effective way to manage basement moisture is to address the source. Dehumidifiers, waterproof paints, and odor‑masking sprays can help temporarily, but they are not substitutes for stopping water entry and controlling humidity at its origin.

Basement waterproofing specialists echo this. They repeatedly warn that simply painting interior walls or running a dehumidifier, while ignoring poor grading, clogged gutters, or cracks, leads to recurring problems, including mold behind finishes and slow structural damage.

A simple example makes this clear. Imagine a basement where the RO system sits on a wall that occasionally shows damp patches after heavy rain. You could wipe the wall, run a dehumidifier, and keep cleaning mold as it appears. Or you could step outside, find that the soil slopes toward the house and the downspout dumps water right at the foundation, and correct those issues. The second approach costs some effort up front but dramatically reduces the moisture burden that your RO area will ever see.

Keep Water Away From The Foundation

Multiple sources, including All‑Star Basements, EverDry Toledo, Ohio State Waterproofing, and Waterproof Magazine, converge on one theme: surface‑water management is your first defense.

They recommend clear, simple actions such as maintaining gutters so they are not clogged, extending downspouts several feet from the house, and grading the soil so it slopes away from the foundation. Some detailed guidance includes a typical target of about 6 inches of drop over 10 feet of distance away from the house, and downspouts that discharge roughly 4 to 6 feet away, or even more in very wet or clay‑soil sites.

A real‑world example helps visualize this. If you stand ten feet out from your foundation and measure up the wall, the soil at your feet should be roughly half a foot lower than the soil right against the house. Homeowners sometimes confirm this with a straight ten‑foot board and a level: one end rests against the foundation, the other sits on the yard, and they adjust soil until they see approximately that six‑inch difference.

Where grading and gutters are not enough, or where groundwater is persistently high, articles from Ohio State Waterproofing, This Old House, Ark Basement Services, and others describe perimeter drains and sump pumps as critical. Exterior French drains set in gravel can intercept groundwater before it reaches the wall, while interior drains and a sump pump collect water that does get in and pump it safely away. In flood‑prone areas, professional sources recommend pumps with battery backups and periodic testing so they work during storms and power outages.

Keeping rain and groundwater out does not just protect your foundation; it also makes the air around your basement RO system far easier to keep dry and mold‑resistant.

Dry The Air With Ventilation And Dehumidification

Moisture does not only arrive as liquid water. Several sources, including Georgetown University’s environmental health guidance, Waterproof.com, DFX Foundation & Waterproofing Experts, and Mold and basement articles summarized from This Old House, warn that elevated humidity is enough to let mold grow, even when you do not see leaks.

Research‑backed recommendations for basements converge on two targets: keep relative humidity below about 60 percent, and ideally in the 30–50 percent range, and avoid trapping stale, moist air. Dehumidifiers are widely recommended as a first‑line tool, especially in below‑grade spaces. Waterproofing specialists often suggest sizing a unit to the square footage and dampness of the basement, with some sources giving a typical capacity in the range of around 70 pints of moisture removal per day for an average basement.

Ventilation is the other half of the equation. A ventilation expert cited in Waterproof Magazine notes that the Environmental Protection Agency encourages multiple air exchanges per day to help manage indoor pollutants and moisture. In a basement, that is often achieved with mechanical ventilation that exhausts stale air and brings in drier air from outside or the upper levels of the home, supplemented by fans to move air into corners and behind equipment.

Here is a simple calculation to frame the problem: suppose your basement is 1,000 square feet with an average ceiling height of 8 feet.

That is about 8,000 cubic feet of air. If you aim for several air exchanges per day, you want enough ventilation and airflow that those 8,000 cubic feet cycle through your system multiple times, rather than stagnating around your RO tank, pipes, and stored items. Fans placed intelligently so air can pass around and behind the RO unit help ensure there are no “dead zones” where humid air just sits.

Seal, Insulate, And Use Moisture Barriers Strategically

Interior and exterior waterproofing materials are most effective when they are part of a complete moisture strategy rather than a standalone fix. Polyguard and other building envelope experts describe moisture barriers as systems that stop liquid water and water vapor from penetrating walls and floors, reducing structural damage and mold risk.

Exterior solutions include sheet membranes or liquid‑applied coatings on the outside of foundation walls, plus drainage mats that create a channel for water to move down to footing drains. Interior approaches can include waterproof coatings on masonry, but university extension sources caution that interior coatings without proper drainage often trap water in the wall and eventually fail.

Vapor barriers and insulation play a specific role for mold prevention around basement RO systems. A common recommendation is to use at least a 6‑mil polyethylene sheet as a vapor barrier on basement floors before finishing materials, and rigid foam insulation on walls to reduce condensation. When warm, moist air meets a cold, uninsulated wall, the temperature difference can cause condensation, which then soaks nearby framing or finishes. Insulation moderates that temperature swing; vapor barriers keep water vapor from migrating into materials beneath.

For RO installations, that means putting equipment in an area where the walls and floors are already well sealed and insulated, not against a bare, sweating concrete wall. It also means insulating exposed cold‑water lines, as EverDry Toledo and other basement resources recommend, to prevent “sweating” pipes that drip onto the floor near your filtration system.

Step Two: Design And Place Your Basement RO System To Avoid Mold Hotspots

Choose A Location With Dry, Stable Conditions

From a mold standpoint, not all corners of a basement are equal. Guidance from extension services and mold‑awareness programs notes that mold often appears where air circulation is poor, such as behind furniture, appliances, or shelving, and in areas where moisture seeps through walls or floors.

When deciding where to install a basement RO system, it helps to think like a moisture detective. Avoid areas that:

- Smell persistently musty.

- Show efflorescence, which looks like white, powdery deposits on masonry and indicates moisture has been evaporating through the wall.

- Have a history of dampness after rain.

- Sit right against a cool exterior wall with no insulation.

Instead, favor a zone where previous waterproofing work has already been done, where walls are insulated and finished with moisture‑resistant materials, and where there is enough room behind and around the equipment for air to circulate. A small gap between the RO tank and the wall, and between the system and any shelving, reduces the risk that moist air stays trapped.

As a hydration specialist, I often suggest that homeowners treat the RO area as a “dry zone” that gets extra attention during waterproofing. If you are already investing in membranes, vapor barriers, and insulation, it is smart to prioritize the future RO wall and floor so you know your system will sit in the most controlled part of the basement.

Manage Drainage And Condensation Around The System

Basement mold case studies repeatedly point to cove joints (where walls meet floors), poorly drained window wells, and unvented appliances as common problem spots. An RO system can add its own localized challenges if the area around it is not designed with drainage and condensation in mind.

Several practical implications follow from the basement research:

If there is a floor drain nearby, make sure it is functioning and kept clear, not clogged or covered by boxes or furniture. Many DIY waterproofing guides emphasize regular inspections of wall‑floor junctions and drains to catch early signs of seepage or standing water. The same diligence should extend to the part of the floor where your RO lines and storage tank sit.

Condensation on cold lines and tanks can be reduced by insulating pipes and, where appropriate, the exterior of metal plumbing components that tend to sweat. As noted in basement maintenance articles, low‑cost foam sleeves on cold‑water pipes are surprisingly effective at eliminating drips that raise humidity. When those pipes run directly to or above your RO system, the benefit is not just comfort; it is mold prevention.

If your RO system drains into existing plumbing, make sure connections are secure and accessible for inspection. Research on basement leaks and mold stresses the importance of promptly fixing small leaks before they escalate; that is only possible if you can actually see fittings and joints rather than burying them behind finished walls or deep inside cluttered storage.

Favor Mold‑Resistant Surfaces And Surroundings

Several basement waterproofing and renovation articles highlight that material choices can make a big difference in mold risk. For floors, non‑porous or low‑absorption options like sealed concrete, ceramic tile, or properly installed vinyl are easier to keep dry and clean than carpet or unfinished wood. For walls, moisture‑resistant panels, cement board, and properly detailed insulation outperform standard drywall in damp‑prone spaces.

When planning a basement RO installation, aim to surround it with these more resilient materials. For example, placing an RO system on a sealed concrete pad with a slight lip, against an insulated wall covered with moisture‑resistant finishes, means that if a minor leak does occur, water is less likely to soak into carpet or untreated framing. Because mold grows readily on damp organic material, reducing absorbent surfaces near the system reduces the chance that a minor event becomes a major mold colony.

This is consistent with broader mold guidance from real estate and home‑renovation sources, which recommend using mold‑resistant materials in basement finishes and avoiding storing cardboard boxes, fabrics, or firewood directly on the floor against exterior walls. Around your RO system, that translates to keeping cardboard packaging, paper filters, and spare parts in plastic bins on shelving, not stacked on the floor against the wall.

Step Three: Operate And Maintain Your System With Mold Prevention In Mind

Monitor Humidity And Temperature Around The RO Area

Basement mold prevention articles repeatedly recommend a simple, inexpensive tool: a digital hygrometer. Sources such as Waterproof.com and home‑maintenance guides suggest keeping indoor relative humidity between about 30 and 50 percent, and definitely below 60 percent, with the lower end of that range offering the best protection against mold while avoiding overly dry air.

For a basement RO system, it is useful to place a hygrometer where it can “see” the air the system actually sits in, not just at the staircase or in another room. If you notice that the RO corner stays several percentage points more humid than the rest of the basement, that is a clue that air is not circulating well or that subtle condensation or leaks exist.

Temperature also plays a role. Basements are naturally cooler, and mold grows well in moderate temperatures when moisture is present. When warm, humid air from upstairs or outside meets a cool basement, condensation can form on walls, pipes, and metal parts, including around an RO system. University and extension advice for basements includes avoiding direct summertime ventilation with very humid outdoor air; instead, they suggest using air conditioning or controlled ventilation to manage both temperature and humidity.

Build A Simple Inspection Habit

Almost every expert source on basement moisture and mold stresses the value of regular, proactive inspection. Waterproofing companies describe monthly or seasonal checklists for gutters, downspouts, sump pumps, and basement surfaces. Mold guidance from NDSU Agriculture and others notes that problem areas often include basements, bathrooms, laundry rooms, kitchens, closets, and behind furniture.

You can adapt this mindset to your basement RO system by adding a short, consistent routine:

Look at the floor around the RO unit, paying attention to the wall‑floor junction and under any tubing or valves. You want to catch small puddles, rust spots on nearby metal, or discolored concrete.

Feel the main lines and fittings briefly to check for dampness or active drips.

Smell the area for musty or earthy odors, especially after heavy rain or when the dehumidifier has been off.

Check nearby walls for peeling paint, bubbling finishes, or new stains, all of which basement mold articles list as early warning signs.

This routine does not have to take more than a couple of minutes once a month, especially if you tie it to other maintenance you already do, such as changing prefilters or checking the dehumidifier bucket or hose.

The key is consistency; many severe mold problems documented by real estate and restoration professionals started as a small, unnoticed leak or damp patch.

Respond Quickly To Wet Events

The EPA’s brief guide on mold and moisture emphasizes a crucial timing point: water‑damaged materials should be dried within 24 to 48 hours to minimize mold growth. ServiceMaster and other restoration specialists echo this, noting that mold can begin to colonize wet materials within roughly a day or two after a flood or leak.

For a basement RO system, this translates into a simple rule: any time you discover a leak, spill, or condensation issue, aim to have the area fully dry within that same 24–48‑hour window. That means more than just blotting up visible water. It includes:

Drying the floor with towels or a wet vacuum if necessary.

Running dehumidifiers and fans aimed at the affected zone, not just the general basement.

Moving any nearby cardboard boxes, fabrics, or wood items so they can dry separately and do not stay in contact with damp surfaces.

As an example, imagine you notice at 6:00 PM that a fitting above your RO tank has been dripping slowly, leaving a damp ring on the concrete. If you repair the fitting, dry the concrete thoroughly, run the dehumidifier overnight, and ensure the surface is dry by the next evening, you have significantly reduced the chance that mold gets established. Waiting several days to act gives spores time to settle and feed on dust and residues.

Know When Mold Is A DIY Issue And When To Call Professionals

Several sources, including Realtor‑focused guidance, the EPA, and waterproofing specialists, draw a line between small, localized mold patches and larger, more complex situations.

Small patches on non‑porous surfaces, under about ten square feet, can often be addressed by homeowners who are not immunocompromised, using appropriate protective equipment such as gloves and masks, and cleaning with detergent and water or suitable disinfectants. Even then, the guidance is clear that cleaning is only half of the job; you must also fix the underlying moisture source, whether that is a leak, persistent condensation, or high humidity.

Larger affected areas, suspected highly toxigenic molds, or mold that involves porous building materials such as drywall, insulation, or large sections of framing, generally require professional remediation. Real‑estate guidance cites typical basement mold removal costs in the range of several thousand dollars, especially when combined with optional waterproofing, but that investment is often necessary to protect health and property value.

If the mold is concentrated around your RO system, involving nearby walls, ceilings, or framing, it is also important to coordinate between mold remediation and waterproofing or foundation specialists. Contractors like All‑Star Basements, DFX Foundation & Waterproofing Experts, and Ohio State Waterproofing emphasize that long‑term solutions usually combine drainage improvements, crack repairs, membranes, ventilation, and humidity control rather than one isolated treatment.

When Your Basement Is Not Ready For An RO System

Red Flags That Should Come First

Before installing or expanding a basement RO system, it is wise to assess whether the space is ready from a mold and moisture standpoint. Drawing on patterns highlighted by university extensions, waterproofing companies, and mold guidance, you should be cautious if you notice:

A persistent musty odor as soon as you open the basement door, especially if it intensifies in humid weather.

Visible mold on walls, floors, contents, or ceilings, even in small patches.

Water stains, peeling paint, or bubbling finishes on masonry or drywall.

Frequent dampness on walls or at the wall‑floor line after rain.

Efflorescence, indicating ongoing moisture movement through masonry.

Relative humidity that regularly sits above about 60 percent, even with occasional dehumidifier use.

In basements with these conditions, it is usually better to focus on waterproofing and moisture control first. That can include grading and drainage improvements, gutter and downspout maintenance, crack sealing, drains and sumps, ventilation upgrades, and dehumidification. Only once the space is stable, dry, and well ventilated does it make sense to add a water treatment system that depends on a reliable, mold‑resistant environment.

How Waterproofing And Water Treatment Work Together

Waterproofing and moisture management are not just about avoiding damage; they also improve the overall value and usability of the home. Waterproof Magazine cites industry experience showing that waterproofed basements can significantly increase market value and make homes more attractive to buyers. Some experts even note that insurers and lenders view well‑protected basements as lower risk.

From a hydration and wellness perspective, a properly waterproofed and ventilated basement benefits your RO system in several ways. It reduces the chance of damage to the equipment from leaks or corrosion, makes it easier to meet recommended humidity targets, and creates a healthier air environment for anyone working near the system to change filters, check valves, or adjust settings.

In many projects I have been involved with, the most durable results came when a homeowner brought in both a reputable waterproofing contractor and a water treatment professional. The waterproofing specialist focused on grading, drains, membranes, sump pumps, and structural issues. The water treatment professional then designed the RO system and any pre‑ or post‑treatment to fit into the newly controlled environment, choosing locations, supports, and routing with moisture in mind.

FAQ: Basement RO Systems And Mold

Can an RO system itself cause mold?

An RO system does not feed mold with nutrients, but it does introduce plumbing, fittings, and pressure lines that can leak or condense. Environmental and building‑science sources agree that mold growth is driven by moisture; wherever water repeatedly lands on organic materials or dust, mold can follow. That means any drips, sweating pipes, or damp floors around your RO system can support mold, even if the treated water itself is clean. The key is to treat the RO as part of your overall moisture plan: prevent leaks, insulate cold lines, and keep the surrounding area dry and well ventilated.

What humidity level should I aim for around a basement RO system?

Basement mold and indoor air quality guidance from multiple sources recommend keeping relative humidity below about 60 percent and ideally in the 30–50 percent range. Using a digital hygrometer near your RO system is a simple way to monitor conditions. If you consistently see readings above that range, especially in warmer months, you may need to adjust dehumidifier settings, improve air circulation, or revisit drainage and waterproofing. Keeping humidity in that target band benefits both mold prevention and general comfort.

Is a dehumidifier enough to protect my basement RO area from mold?

Dehumidifiers are valuable tools and are recommended by waterproofing and mold‑prevention experts for basements, but university extension research cautions that they are not complete solutions on their own. By drying the air, they can actually pull more moisture through damp walls and slabs if exterior drainage and leaks are not corrected. The most reliable approach is layered: control moisture sources with grading, gutters, drains, and crack repairs; seal and insulate appropriately; and then use a dehumidifier and ventilation to keep humidity in the ideal range around your RO system.

Every basement RO system I am comfortable endorsing has two things in common: excellent water quality and a basement that is as thoughtfully managed as the filtration itself. When you treat moisture control, waterproofing, ventilation, and system design as one integrated project, you protect your family’s health, your home’s value, and the long‑term performance of your hydration system all at the same time.

References

- https://www.epa.gov/mold/brief-guide-mold-moisture-and-your-home

- https://extension.umn.edu/moisture-and-mold-indoors/moisture-basements-causes-and-solutions

- https://ehs.georgetown.edu/environmental-affair/mold/

- https://www.shawnee.k-state.edu/family-finance/pdfs/Controling%20mold.pdf

- https://www.ndsu.edu/agriculture/extension/publications/molds-your-home

- https://www.thebasementace.com/top-methods-on-how-to-dry-out-basement-quickly-and-effectively

- https://allstarbasements.com/a-homeowners-guide-to-basement-waterproofing-best-practices-and-effective-techniques/

- https://dfxrepair.com/strategies-for-mold-prevention-in-basement/

- https://everdrygrandrapids.com/5-steps-to-a-dry-healthy-basement-year-round/

- https://everdrytoledo.com/5-ways-help-keep-basement-dry/

Share:

Can Reverse Osmosis Make Volcanic‑Ash–Polluted Water Safe to Drink?

Special Treatments for Well Water Contaminated by Agricultural Fertilizers