When people ask me why two “reverse osmosis” systems with the same advertised capacity deliver such different performance, my answer almost always comes back to the membrane module. As a Smart Hydration Specialist, I see this in everything from compact under‑sink filters to high‑recovery well‑water systems: the membrane geometry – especially spiral wound versus hollow fiber – quietly determines how clean your water gets, how often you need maintenance, and what your long‑term costs look like.

This guide walks through the science and the practical trade‑offs of spiral‑wound and hollow‑fiber membranes, using evidence from industrial and academic studies, but translating it into everyday decisions for healthy drinking water at home.

Reverse Osmosis 101: What the Membrane Actually Does

Membrane filtration is a pressure‑driven process. A pump pushes water against a semi‑permeable barrier so that cleaner water (the permeate) passes through and more contaminated water (the concentrate) is left behind. A technical note from Membrane Specialists LLC describes this as splitting a single feed into a more concentrated stream and a purified stream that you can drink or reuse.

Across the “membrane spectrum,” different pore sizes target different contaminants. According to that same engineering guide:

- Reverse osmosis sits at the tightest end, holding back essentially all dissolved salts and many small organic molecules.

- Nanofiltration, ultrafiltration, and microfiltration progressively allow more dissolved species through and mainly remove larger particles and microorganisms.

Reverse osmosis is what turns brackish or seawater into fresh water and polishes tap water into low‑TDS drinking water. In modern systems, the active separating layer is usually a thin‑film composite (TFC) polyamide. An industry overview of commercial seawater RO membranes notes that all four major global suppliers focus on these cross‑linked aromatic polyamide TFC spiral‑wound elements, achieving salt rejections around 99 percent and very high water productivity.

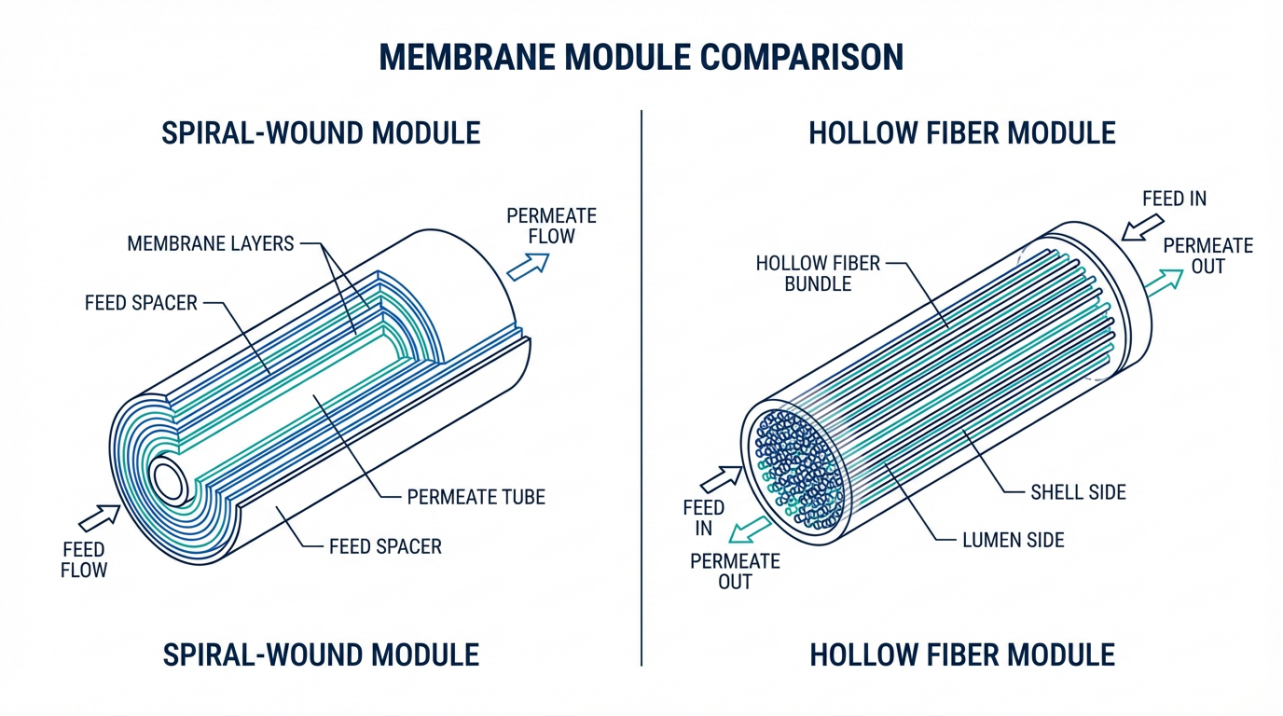

The membrane itself is only half the story. To actually use it, manufacturers package it into a module. Two of the most important module geometries are spiral‑wound and hollow fiber. They both carry TFC or other selective layers, but the way water flows through them – and how easy they are to keep clean – is very different.

Quick Definitions: Spiral-Wound vs Hollow Fiber Modules

Before we dive into pros and cons, it helps to pin down what each configuration looks like in practice.

Spiral‑wound modules use flat membrane sheets. A technical review of spiral‑wound modules for groundwater treatment describes how manufacturers stack membrane envelopes and spacer meshes, then wrap them around a perforated central tube to form a cylinder. Standard elements are about 40 inches long and often 4 or 8 inches in diameter. A typical full‑scale 8‑inch element contains on the order of 440 square feet of active membrane area, all packed into a tube just over 3 feet long.

Hollow fiber modules use thousands of tiny, straw‑like fibers. Engineering notes from Synder Filtration and Nigen describe them as capillary‑sized tubes about 0.04 to 0.14 inches across. The fiber walls are porous or selectively dense, and water flows either from outside to inside the fiber or the reverse. One Nigen technical article notes that a standard hollow‑fiber module with a fiber bundle around 4 inches in diameter can offer about 600 square meters of surface area, which is roughly 6,500 square feet of membrane in a surprisingly compact shell.

In both cases, you are buying a membrane plus a hydraulics design.

The way those flow channels are arranged governs pressure losses, fouling behavior, how thoroughly you can clean the module, and ultimately how reliably your RO system will protect your family’s water.

Spiral-Wound RO Membranes In Detail

How Spiral-Wound Elements Are Built

From the outside, a spiral‑wound element looks like a simple cartridge. Inside, it is a very carefully engineered roll.

A review in Frontiers in Membrane Science and Technology describes the structure as three main parts:

- Flat‑sheet thin‑film composite membrane envelopes that do the separation.

- Feed spacers, which are net‑like polymer meshes that create flow channels and turbulence on the feed side.

- Permeate spacers and a perforated central tube that collect and carry the treated water.

Manufacturers typically connect three to eight elements in series inside a pressure vessel and then arrange several vessels in parallel to build a complete RO stage. That same review emphasizes that spacer geometry – the angles and thickness of the plastic filaments – strongly influences pressure drop and concentration polarization, so modern element design is as much about internal hydrodynamics as it is about the chemistry of the polyamide layer.

Why Spiral-Wound Dominates RO

A comparative article on RO membranes in a roll, as well as multiple engineering reviews, highlight several reasons spiral‑wound membranes have become the mainstream reverse osmosis format across drinking water, industrial, and seawater desalination systems.

Spiral‑wound modules provide high membrane area in a compact footprint. The groundwater treatment review notes that an 8‑inch spiral element can reach around 440 square feet of active membrane area and that several elements can be stacked in a single pressure vessel. This high “packing density” allows designers to treat large flows in a relatively small equipment room or under a kitchen sink.

They also support high operating pressure. Seawater RO elements in large desalination plants routinely run at pressures on the order of hundreds of pounds per square inch, something spiral‑wound modules are specifically built to withstand. A review of dominant commercial seawater RO membranes describes how national projects in Japan and Korea have progressively optimized these TFC spiral‑wound elements to deliver high flux at lower pressure, directly reducing energy use per gallon of water produced.

Spiral‑wound construction is robust and standardized. Elements are manufactured in industry‑standard lengths and diameters. Major suppliers like Toray, DuPont Water Solutions, Hydranautics, and LG Chem all offer spiral‑wound product lines. This standardization matters in practice: in my field audits, I consistently see that operators can replace a fouled or damaged spiral‑wound element with an equivalent model from another reputable brand without redesigning the whole skid.

Cost per treated gallon is favorable. Both a membrane module comparison article and manufacturer application notes point out that spiral‑wound modules leverage their high packing density to deliver a low cost per unit of water treated, especially in RO and nanofiltration service. The construction is relatively simple compared with more open plate‑and‑frame formats, which keeps manufacturing costs under control.

The Hidden Drawbacks Of Spiral-Wound

No membrane design is perfect, and spiral‑wound elements have trade‑offs that matter more as feed water gets “dirtier.”

Fouling in narrow channels. The same tight feed spacers that give high area per unit volume also create narrow channels where suspended solids and biofilms can accumulate. A qualitative comparison of membrane module types notes that spiral‑wound elements tend to foul when treating high‑solids or otherwise challenging feeds, and a groundwater review echoes that feed spacer geometry can exacerbate concentration polarization near the membrane surface.

Harder cleaning and higher pressure drop. Because the membrane sheets are tightly wound, you cannot easily disassemble a spiral‑wound element to scrub or access internal surfaces. A forward osmosis study archived in PubMed Central compared spiral‑wound and plate‑and‑frame modules and found that spiral‑wound units, with their long narrow channels, suffered from high pressure drops and were more difficult to clean thoroughly. Even though that study focused on forward osmosis, the hydraulics are closely related in RO geometry as well.

Dependence on good pretreatment. A membrane selection guide from Membrane Specialists LLC notes that spiral‑wound modules “require good prefiltration to avoid clogging” of the narrow feed channels. In practical terms, that means your home RO system relies heavily on upstream sediment filters and carbon cartridges to protect the spiral‑wound membrane from particulate and organic fouling. When those prefilters are neglected, I routinely see premature membrane failure or rapid pressure‑drop increase across the RO stage.

Taken together, spiral‑wound RO membranes offer an excellent balance of compactness, high rejection, and mature technology, as long as they are paired with appropriate pretreatment and sensible operating conditions.

Hollow Fiber Membranes In Detail

What Hollow Fiber Modules Look Like

Hollow fiber modules take a very different approach. Instead of wrapping sheets around a tube, they fill a shell with thousands of tiny flexible straws.

An engineering overview from Synder Filtration describes those fibers as 1 to 3.5 millimeters wide, bundled and potted into a PVC shell. The pores are in the tube wall, and water flows either inside‑out or outside‑in. A Nigen technical article adds a striking scale example: a hollow‑fiber module with a fiber bundle about 4 inches in diameter can provide up to about 600 square meters of membrane area, which is roughly 6,500 square feet of surface.

These modules can be manufactured across the separation spectrum, from microfiltration and ultrafiltration (with pore sizes down to about 0.01 microns) through nanofiltration and even dense RO‑type selective layers. A review of hollow fiber membranes for wastewater and resource recovery points out that hollow fibers are now common in ultrafiltration, forward osmosis, pressure‑retarded osmosis, membrane distillation, and membrane contactors for gas or nutrient transfer.

In drinking water and pretreatment applications, the most common hollow‑fiber products are ultrafiltration or microfiltration units that remove particles, bacteria, and many protozoa while leaving most dissolved salts and minerals in the water.

Strengths Of Hollow Fiber Membranes

Very high packing density in a compact module. By shrinking the flow channels down to many small fibers, manufacturers can tuck immense surface area into a small housing. Both Synder Filtration and Nigen highlight this as a primary advantage: hollow fibers offer very high membrane area per unit volume, making them attractive wherever space is limited but throughput demands are high.

Excellent microbiological barrier. A Nigen engineering note describes typical hollow‑fiber ultrafiltration pore sizes around 0.2 microns, with versions as tight as 0.01 microns. A separate technical note from JIUWU Hi‑Tech reports that hollow‑fiber drinking water modules can achieve more than 6‑log removal of bacteria and more than 4‑log removal of viruses. In plain language, that is a very strong barrier against microbial contamination when the membrane is intact and operated correctly.

High flux and water recovery in pretreatment roles. The JIUWU technical document reports high water flux and recovery in both tap water and surface‑water applications, as well as in seawater desalination pretreatment. Those hollow‑fiber ultrafiltration steps produce water that meets stringent silt density index thresholds for feeding downstream RO, while also offering high overall water yield and relatively small footprint.

Backwashability and air scouring. One of the most practical benefits for operators is that many hollow‑fiber systems allow backflushing and sometimes air scouring from the permeate side. The Synder Filtration overview notes that this makes them well‑suited for feeds with high total suspended solids, because periodic backwash cycles can dislodge fouling layers and restore flux without opening the module.

Operational flexibility and low driving pressure for UF. The Membrane Specialists LLC selection article notes that hollow‑fiber ultrafiltration modules often run at relatively modest pressures, and JIUWU reports high flux at low driving pressure in both municipal and surface‑water service. Nigen also highlights that, in some gravity‑driven configurations, hollow‑fiber modules can operate with little or even no electrical energy by relying on height differences rather than pumps, which is particularly attractive in remote or emergency applications.

Broad industrial and medical track record. Beyond drinking water, hollow fibers are widely used in membrane bioreactors, juice processing, dialysis, and biopharmaceutical separations. A dairy microfiltration study archived in PubMed Central compared tubular ceramic, spiral‑wound, and hollow‑fiber modules for milk protein fractionation. In that work, industrial‑scale hollow‑fiber modules showed competitive flux and protein transmission compared with ceramic and spiral‑wound systems when performance was evaluated per module, not just per unit membrane area. That kind of evidence reinforces that hollow‑fiber modules are a mature technology, not a laboratory curiosity.

Limitations And Risks Of Hollow Fiber

At the same time, multiple technical and manufacturer sources are candid about the drawbacks of hollow‑fiber membranes, especially in long‑term, high‑duty service.

Susceptibility to fouling. A Membrane Solutions engineering blog identifies fouling as the primary drawback: suspended solids, organics, microorganisms, and colloids build up on fiber surfaces or within pores, driving flux down unless pretreatment and cleaning are carefully managed. The wastewater review on hollow fibers lists numerous examples where fouling control – not intrinsic membrane performance – limits practical flux in real effluents.

Mechanical fragility and fiber breakage. Both Synder Filtration and Membrane Solutions emphasize that hollow fibers are relatively delicate. Fibers can break due to pressure shocks, aggressive backwashing, or physical mishandling. A membrane selection guide from Membrane Specialists LLC notes that many polymeric hollow‑fiber ultrafiltration modules should not be operated above roughly 2 bar, which is on the order of 30 psi, to avoid fiber breakage. When fibers do break, they can create “short‑circuit” paths that allow untreated water to bypass the membrane unless the module has robust integrity monitoring.

Chemical and temperature limits. Most hollow‑fiber membranes for water treatment are polymeric, such as PVDF, PES, or polypropylene. Membrane Solutions notes that these materials have defined pH and temperature windows; harsh chemicals or high temperatures accelerate aging and can shorten membrane life. In very aggressive environments, ceramic or other specialized materials may be needed, but those come with higher capital costs and are more common in tubular or plate‑and‑frame formats.

More involved cleaning and operating costs. Because hollow‑fiber modules have very large internal surface area and delicate fibers, cleaning protocols must be well designed. The Membrane Solutions article points out that operating costs can be higher than expected once you factor in cleaning chemicals, downtime for backwash or chemical cleaning, and more frequent replacement when fibers break. Synder Filtration describes hollow‑fiber systems as having moderate capital cost but higher operating cost than some spiral‑wound systems.

Need for sterilization and careful handling. The JIUWU technical note on hollow‑fiber ultrafiltration for drinking water emphasizes that ultrafiltration membranes retain bacteria but do not kill them. They recommend regular sterilization cycles using disinfectants such as sodium hypochlorite or hydrogen peroxide, with frequencies that depend on raw water quality and temperature. The same document warns that hollow‑fiber modules are precision components that must be handled gently, flushed thoroughly to remove protective liquids before use, and protected from freezing to avoid irreversible damage.

From a homeowner or facility manager’s perspective, hollow‑fiber membranes can be powerful tools, especially as pretreatment stages, but they demand respect in design and operation.

Spiral-Wound vs Hollow Fiber: Side-by-Side Comparison

The table below summarizes key differences drawn from technical reviews, manufacturer notes, and comparative studies. Remember that many hollow‑fiber products used with RO are ultrafiltration or microfiltration modules, not RO membranes themselves, so the separation level is often different.

Feature |

Spiral-Wound RO |

Hollow Fiber RO/UF |

Physical form |

Flat TFC sheets and spacers wrapped around a central tube to form a cylinder (often 40 inches long, 4–8 inches diameter). |

Thousands of tiny porous fibers bundled into a shell, with water flowing inside‑out or outside‑in. |

Typical separation range |

Dominant format for RO and widely used for nanofiltration in both drinking water and desalination plants. |

Common as ultrafiltration and microfiltration for drinking water, surface water, wastewater, membrane bioreactors, and RO pretreatment; also used in FO, PRO, MD, and membrane contactors. |

Packing density |

High packing density; one 8‑inch element can have roughly 440 square feet of membrane area, and several elements fit in one pressure vessel. |

Very high packing density, with some modules around 4 inches in diameter offering about 6,500 square feet of membrane area in a compact vessel. |

Pressure and robustness |

Built for high pressure; commercial seawater RO elements operate at high hundreds of psi with robust housings and anti‑telescoping devices. |

Many polymeric hollow‑fiber UF modules are limited to around 30 psi to avoid breakage; higher‑pressure hollow fibers exist but require careful engineering. |

Fouling and cleaning |

Narrow flow channels are prone to fouling and concentration polarization; cleaning is more challenging because the element is tightly wound and not easily opened. |

Backwashable and air‑scourable, better at handling high suspended solids; however, fouling is still a major constraint and cleaning protocols are more complex. |

Mechanical failure modes |

Generally robust modules; failures are more often related to long‑term fouling or chemical attack than to catastrophic breakage. |

Thin fibers are vulnerable to breakage during operation or handling, which can compromise integrity if not detected and addressed. |

Operating and maintenance cost |

Favorable cost per gallon treated due to high area and standardized manufacturing; requires good pretreatment to control fouling. |

Moderate capital cost but potentially higher operating cost because of cleaning frequency, chemical consumption, and fiber replacement. |

Typical uses relevant to drinking water |

Under‑sink and whole‑house RO, brackish and seawater desalination, polishing stages in advanced treatment trains. |

Cartridge‑type UF filters for tap and well water, membrane bioreactor modules, surface‑water and seawater pretreatment ahead of RO, specialized industrial and medical applications. |

What This Means For Your Home RO or Filtration System

In the field, I rarely see homeowners choosing a membrane geometry explicitly; they choose a system for taste and safety, and the membrane type comes along for the ride. Understanding these differences lets you ask better questions and match technology to your actual source water.

If your source water is municipal tap with moderate hardness and relatively low turbidity, a spiral‑wound thin‑film composite RO membrane with sediment and carbon pretreatment is usually the most straightforward path to low‑TDS, good‑tasting water. This mirrors the design of countless commercial and municipal systems described in the groundwater and seawater RO reviews, where spiral‑wound elements are the default.

If your water is high in suspended solids, color, or organic matter – common with surface water, shallow wells, and some small community supplies – incorporating hollow‑fiber ultrafiltration as a pretreatment step can be a smart move. The JIUWU and Synder Filtration technical notes show hollow‑fiber UF excelling at removing particles and microorganisms while delivering high flux and water recovery, and they specifically recommend it as pretreatment to stabilize feed quality for downstream RO.

If you are dealing with high salinity, such as brackish well water or seawater, you will almost certainly rely on spiral‑wound RO elements. Reviews of dominant commercial SWRO technologies make clear that these TFC spiral‑wound modules from major suppliers form the backbone of modern desalination plants, where high pressure and high rejection are non‑negotiable.

If you are designing an off‑grid or emergency system, hollow‑fiber modules can shine when used correctly. The Nigen overview highlights gravity‑driven hollow‑fiber filters that achieve strong microbiological removal with little or no electrical energy. In those cases, understand that the membrane is acting more like a high‑end ultrafilter: fantastic for pathogens, but not a substitute for RO when you need to reduce dissolved salts, nitrates, or small organic contaminants.

Caring For Each Type To Protect Water Quality

Good Practice With Spiral-Wound RO Elements

Even though spiral‑wound modules are robust, the research and manufacturer notes converge on a few practical themes.

Protect them with pretreatment. The Membrane Specialists LLC guide and module comparison articles all stress that spiral‑wound elements need good prefiltration. In a home or light commercial system, that usually means a sediment filter to catch rust and silt, plus carbon to remove chlorine and many organics, before the water touches the RO membrane.

Watch pressure and flow trends. Technical studies of spiral‑wound modules, including the MDPI analysis of feed spacer dimensions, show clear relationships between pressure drop, flow distribution, and performance. On a practical level, if you see rising differential pressure across the RO stage or a sustained drop in permeate flow at constant feed conditions, it is a sign of fouling or scaling. Catching that early allows cleaning before irreversible damage occurs.

Match the membrane chemistry to your disinfectant strategy. A review of RO membrane materials notes that fully aromatic polyamide formulations are engineered for improved chlorine resistance, while older cellulose acetate membranes tolerate chlorine but have other stability limits. The take‑home for a homeowner or facility manager is simple: follow the manufacturer’s guidelines for allowable disinfectant levels and cleaning chemicals so the spiral‑wound element’s active layer is not gradually destroyed.

Good Practice With Hollow Fiber Modules

Hollow‑fiber membranes reward careful hygiene and gentle handling.

Plan for regular disinfection. JIUWU’s drinking water guidance explains that ultrafiltration retains microorganisms but does not kill them, and recommends periodic sterilization of the filtration system using oxidizing agents like sodium hypochlorite or hydrogen peroxide. The exact frequency depends on raw water quality and temperature, but the underlying principle holds for any hollow‑fiber unit: build disinfection into your maintenance schedule, not just mechanical cleaning.

Handle modules as precision components. The same JIUWU note advises treating hollow‑fiber cartridges as delicate equipment. They should be flushed thoroughly before first use to remove protective solutions, not subjected to mechanical shocks, and stored with appropriate preservatives or antifreeze when idle in cold conditions. My own inspections confirm that many “mysterious” fiber failures trace back to mishandling during installation or storage, not flaws in the membrane itself.

Design pretreatment and cleaning around fouling risk. The Membrane Solutions analysis emphasizes that robust pretreatment – such as screening, clarification, or upstream cartridge filtration – combined with well‑defined backwash and chemical cleaning cycles, is essential to keep hollow‑fiber systems stable. In practice, that means you should not drop a hollow‑fiber module directly into a very dirty stream and expect low‑maintenance operation; invest either in better pretreatment or in module configurations better suited to high solids.

Respect pressure and integrity limits. With many polymeric hollow‑fiber modules, going beyond recommended pressures or backwash intensities is the fastest way to create fiber breaks. Engineers in the dairy and wastewater studies consistently operate hollow‑fiber modules within defined transmembrane pressure ranges and rely more on crossflow, backwashing, and air scouring than on simply pushing harder.

FAQ: Choosing Between Spiral-Wound And Hollow Fiber For Drinking Water

Is a hollow fiber filter enough on its own for safe drinking water?

It depends on what is in your water. Technical notes from Nigen and JIUWU show that hollow‑fiber ultrafiltration can achieve very high removal of bacteria and viruses, making it an excellent barrier against pathogens. However, ultrafiltration membranes do not significantly remove dissolved salts, nitrates, or many small organic molecules. If your main concern is microbes in otherwise low‑salinity water, a hollow‑fiber filter can be a strong solution. If you need to reduce total dissolved solids or specific dissolved contaminants, you still need RO or another desalting step, which in practice usually means a spiral‑wound RO element.

Which membrane type gives better-tasting water?

Taste is mostly driven by dissolved minerals and organics rather than particles or microbes. Spiral‑wound RO membranes are designed to strip out most dissolved salts and many organics, which often yields very low‑TDS water with a clean taste that many people prefer. Hollow‑fiber ultrafiltration, acting alone, leaves the mineral content largely unchanged; that can be desirable when you want to preserve natural mineral character, but it will not fix high salinity or strong taste caused by dissolved contaminants. In many well‑designed systems, hollow‑fiber UF is used upstream to protect a spiral‑wound RO stage, combining microbiological safety with low‑TDS taste.

How do I decide what to install in a new home or small building?

A practical approach, consistent with the membrane selection guidance from Membrane Specialists LLC, is to start with your water analysis and your goals. If your feed is municipal water and your primary goals are taste, reduction of dissolved contaminants, and a simple maintenance routine, a standard spiral‑wound RO system with good pretreatment is usually appropriate. If your source is variable surface water or a small community supply with high turbidity or microbiological risk, a hollow‑fiber ultrafiltration stage, possibly followed by RO if salinity is also an issue, provides additional resilience. Short pilot tests, even at small scale, can be valuable when the raw water is complex.

Healthy hydration at home is not only about what you remove, but about choosing membrane technologies that you can operate reliably for years. Spiral‑wound RO membranes offer proven, high‑rejection performance in a compact and standardized format, while hollow‑fiber modules deliver exceptional microbiological protection and robustness against suspended solids when they are designed and maintained carefully. When you understand how each configuration behaves, you can work with your installer or engineer to build a system that fits your water, your lifestyle, and your long‑term wellness goals.

References

- https://pmc.ncbi.nlm.nih.gov/articles/PMC7693574/

- https://www.osti.gov/servlets/purl/6994228

- https://digital.library.unt.edu/ark:/67531/metadc1194999/

- https://www.twdb.texas.gov/publications/reports/numbered_reports/doc/r363/c6.pdf

- https://www.frontiersin.org/journals/membrane-science-and-technology/articles/10.3389/frmst.2024.1343651/full

- https://www.researchgate.net/publication/238754774_Comparison_of_the_performance_of_hollow_fine_fiber_and_spiral-wound_membranes_in_the_Al-Jubail_SWRO_desalination_plant

- https://www.jiuwumembrane.com/application-progress-and-precautions-of-hollow-fiber-membrane.html

- https://www.membrane-solutions.com/blog-What-Are-the-Disadvantages-of-Hollow-Fiber

- https://www.netsolwater.com/advantages-of-hollow-fiber-membranes-in-industrial-ro-plant.php?blog=6323&srsltid=AfmBOoq-HhmyVv8s6geJ__aZlqJFQW2A-6Vxxe2b6jVTnhfkZfiQtwk_

- https://www.chunkerowaterplant.com/news/reverse-osmosis-membrane-in-a-roll

Share:

Why 304 Stainless Steel Faucets Cost More Than Copper Faucets

Carbon Fiber Filters vs. Traditional Activated Carbon: Which Is Better For Your Home Water?