When people think about smart water filtration or home hydration systems, they usually picture pristine drinking water, sleek faucets, and app-based controls. Behind all of that, though, is a humble but critical component: the pressure pump. And inside that pump, the bearings quietly carry the load, keep the shaft aligned, and make sure your system runs smoothly and safely. As a smart hydration specialist, I can tell you this from experience: if you want consistently clean, great-tasting water with minimal downtime and noise, you cannot ignore bearing wear.

In industrial settings, manufacturers and reliability engineers repeatedly show that bearing and seal problems are among the most common reasons pumps fail. Grundfos data cited by Samotics attributes over sixty percent of pump failures to a short list of causes that includes bearing issues, while WD Bearing Group reports that more than thirty percent of mechanical problems in demanding mud pumps can be traced directly to bearings. Those numbers come from heavy-duty environments, but the physics is the same in the compact booster pump under your sink or in your well system. The good news is that bearing wear is predictable, trackable, and often preventable if you know what to look for.

Why Pump Bearings Matter So Much in Water Systems

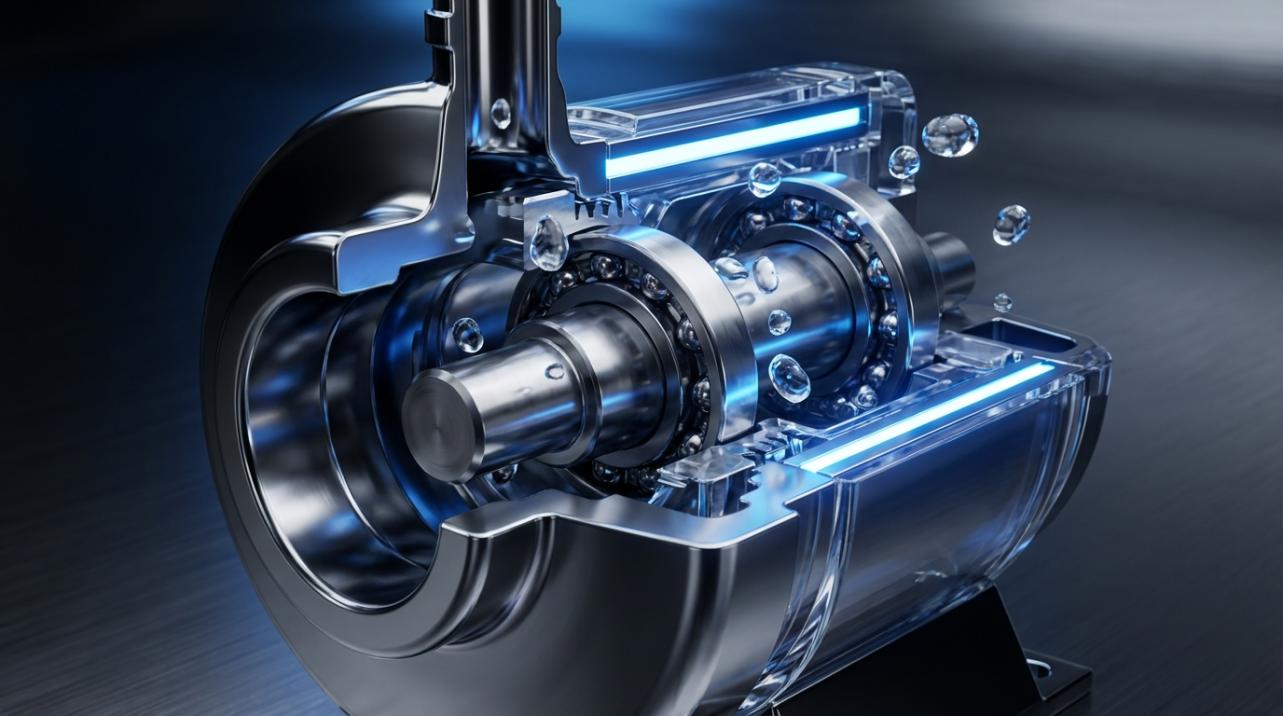

Bearings are precision components that support the pump shaft, reduce friction, and maintain alignment between the motor and the hydraulic elements of the pump. BHS Bearings explains that in compressors, bearings keep the rotor shaft centered and stable; in centrifugal pumps and pressure systems, they play the same role for the rotating assembly that drives water through your filters, lines, and faucets.

When bearings are healthy, they maintain a tiny internal clearance and a stable film of lubricant. Maintenance World notes that in many industrial roller bearings the working radial clearance is only on the order of a few millionths of a meter, which translates to about a few ten-thousandths of an inch. NAXJA engine specialists describe typical oil-film clearances in the range of about 0.001 to 0.003 inch. That slim gap is just enough for an oil or grease film to form, allowing metal surfaces to “float” rather than grind against each other.

Once that relationship breaks down, everything else in your hydration system feels the effect. As NAXJA’s experienced engine builder explains, increasing bearing clearance is like opening a hose nozzle: resistance drops, lubricant leak-off increases, and pressure or oil-film stability falls for the entire system. In pumps, that shows up as more friction, more heat, more vibration, and eventually more noise and leakage. Cornell Pump points out that bearings are often among the first parts to wear, and that replacing them before they damage the shaft can save far more expensive components.

For a simple home example, imagine a small booster pump that runs about two hours a day to maintain pressure for your filtration system. That adds up to roughly 730 hours of operation each year. BHS Bearings cites industrial compressor guidance that calls for lubrication checks about every 500 operating hours. Even though residential duty is usually lighter, you can see how, over a year or two, your home pump quietly accumulates enough run time that its bearings deserve attention long before it fails outright.

What Bearing Wear Actually Is

To catch bearing wear early, it helps to understand what is physically happening inside the pump. BHS Bearings highlights several bearing types commonly used in rotating equipment: ball bearings for general loads and high speeds, roller bearings for heavier loads, sleeve or plain bearings where a continuous oil film supports the shaft, and thrust bearings to carry axial loads. Regardless of type, wear usually appears as a combination of increased clearance, surface damage, and lubricant breakdown.

The bearing clearance story is important. A guide on measuring bearing clearance explains that radial clearance is the space perpendicular to the shaft, while axial clearance runs along it. In new condition, that space is tiny and tightly controlled. Maintenance World reports that many roller bearings in service sit around a few micrometers of internal radial clearance, while NAXJA practitioners emphasize that journal bearings in engines are designed for thin oil films measured in thousandths of an inch. That small gap allows a stable film of lubricant to circulate, which, in theory, could let bearings last indefinitely if metal surfaces never touched.

In real pumps, though, contact does happen. Dry running, where a pump operates without enough liquid, can overheat seals and bearings in minutes, according to Iwaki’s technical glossary. Cavitation, the formation and collapse of vapor bubbles when suction conditions are poor, creates shockwaves that chip away at metal surfaces. Contaminants in the lubricant—dust, rust, metal particles, or moisture—act as abrasives. Maintenance World’s research points out that common contaminants like dust or even residues from fingerprints can be similar in size to the bearing clearance itself, meaning they can easily penetrate the oil film and gouge rolling surfaces. WD Bearing Group adds that contamination from mud and fine particulates accounts for around thirty percent of bearing failures in mud pumps.

As particles scratch the races and rolling elements, tiny pits become stress concentrators. Under repeated load, those pits can grow into flaking and spalling, which NSK, a bearing manufacturer, lists among the defects that make reuse of a bearing unacceptable. At the same time, clearances increase, making the shaft less precisely supported. That leads to higher vibration, more heat, and more load on seals, which in turn increases the risk of leaks and pressure instability. In your home system, that chain of events can turn a once-quiet pressure pump into the rattling, humming device you hear in the basement or under the sink, and can shorten the life of filters and valves that rely on stable pressure and flow.

To make this more concrete, think about a bearing designed with a clearance of about 0.002 inch based on the rule-of-thumb presented in the bearing clearance guide. If wear adds just another 0.001 inch, that is a fifty percent increase in clearance. Around that point, NAXJA’s oil-pressure discussion shows how lubrication becomes much less effective: the film thins, leak-off increases, and system pressures drop. You will not see or measure that tiny gap at home, but you will feel and hear its consequences if you know what to listen and look for.

Early Warning Signs of Bearing Wear in Pressure Pumps

One of the most practical ways to safeguard your home water system is to learn the early warning signs of bearing wear. Industrial guidance from BHS Bearings, Cornell Pump, McLanahan, and PlumbingSupply’s Myers pump article aligns remarkably well: the same symptoms show up whether the pump is driving industrial compressors or pushing drinking water through a filtration system.

Changes in Sound and Vibration

Sound is usually the first giveaway. BHS Bearings describes how grinding or humming noises often increase as compressor bearings wear, and Pumps & Systems details a whole vocabulary of bearing sounds: hissing from rough surfaces, buzzing or roaring from resonance or poor fit, crunching from contamination, clattering when lubrication is low, and sharp screeching when metal surfaces begin to rub directly. In slurry pumps, McLanahan notes that unusual noise can also signal cavitation, which often sounds like marbles rattling through the pump housing.

In a home hydration setup, the cues are more modest but still clear. If your booster pump or well pump used to produce a smooth, steady whir and now has a noticeable growl or rumble that you can feel through the piping or cabinet, that is a classic early sign of bearing distress. The Myers pump guidance points out that excessive vibration is the most common general water pump problem and often traces back to worn bearings or misalignment. Cornell Pump emphasizes that monitoring bearing vibration is one of the most effective ways to detect misalignment, imbalance, cavitation, or looseness before they become catastrophic.

A simple real-world approach is to visit your pump when it is running and rest your hand lightly on the motor housing or pump frame. Establish in your mind what “normal” feels like on a day when the system is healthy and the building is quiet. Repeating that same check every month or so turns your sense of touch into a basic vibration monitor. If you start to notice a harsher buzz, an irregular pulsing, or an obvious increase in movement, that change is often more meaningful than any single decibel number, especially in a residential setting where you do not have industrial instruments.

Heat, Smell, and Housing Condition

Temperature is the next big indicator. BHS Bearings stresses that localized temperature increases at the bearing housing are a key early symptom of wear or lubrication problems. Cornell Pump recommends routine monitoring of bearing temperature, whether through sensors or periodic checks, precisely to catch issues such as lubrication breakdown, misalignment, or cavitation. Pumps & Systems explains that under normal conditions, bearing temperature tends to stabilize a few dozen degrees above ambient and should remain well below severe overheating levels; persistent higher temperatures are a red flag.

In practice, you can think of this in simple terms. If the room is comfortable and your pump housing has always felt warm but touchable during operation, and that suddenly shifts to “too hot to keep your hand on for more than a second or two,” that is a warning sign that friction inside the bearing has increased. BHS Bearings and WD Bearing both note that inadequate lubrication and contamination are dominant causes of rising bearing temperatures, with WD Bearing citing that improper lubrication alone can account for roughly forty to seventy percent of bearing failures in mud pumps, and Samotics highlighting research from RKB suggesting around eighty percent of bearing failures in general are tied to lubrication problems.

NSK’s inspection guidelines also warn that visible discoloration of bearing rings from heat is grounds for replacement. While you will not usually disassemble a home pump yourself, you can still look through ventilation openings for signs of darkened grease, burnt smells around the motor end bells, or staining around bearing caps. Once you see or smell those heat-related signs, it is time to schedule service rather than waiting for a full failure.

Performance Symptoms: Pressure, Flow, Cycling, and Power Draw

The third early warning cluster involves how the system behaves from a water and energy standpoint. Samotics lists reduced flow or pressure, erratic power consumption, and overheating as common early indicators of pump failure, often tied to bearing or seal problems. BHS Bearings highlights that efficiency drops as bearings wear, which shows up as higher energy use for the same output. McLanahan notes that rising or suddenly changing power consumption often means a pump is working harder to overcome internal wear or flow problems.

For home users, this might look like longer wait times for adequate pressure at a filtered tap, more frequent cycling of a well pump, or a booster pump that seems to run louder and longer just to maintain the same shower experience. The Myers pump article explains that drops in water pressure or flow are commonly caused by worn impellers or liners, but also ties strong vibration and cycling issues directly to worn bearings or misalignment. It also points out that pressure-tank air charge should be kept about 2 psi below the pump’s cut-on pressure for proper cycling. That means if your pump turns on at 40 psi, the tank precharge should sit around 38 psi. If you have the tank properly set yet notice the pump starting and stopping more frequently than it used to, that change can be a subtle sign that internal performance has degraded, possibly due to bearing wear increasing mechanical losses.

Tracking power consumption over time adds another lens. McLanahan and BHS Bearings both mention that trending power draw, even with simple readings, can reveal when a pump is becoming less efficient. If your smart home system or utility meter shows a noticeable uptick in energy use during pump operation, but your household water use has not changed, that gap is worth exploring. It might be a failing impeller or clogged filter, but bearing wear is often part of the picture when mechanical friction climbs.

Practical At-Home Checks vs Instrumented Monitoring

Many homeowners assume that bearing health can only be assessed with specialized vibration analyzers or sophisticated condition-monitoring equipment. While those technologies absolutely have their place, especially in municipal or commercial plants, the combination of simple at-home checks and targeted professional monitoring can give you much of the same protection.

Hands-On Checks You Can Do Safely

Across industrial sources, there is strong agreement that regular visual and acoustic inspection is foundational. Cornell Pump urges operators of municipal pumps to maintain a formal inspection schedule and to look for unusual vibration, new noises, seal leaks, and corrosion or buildup. Hydro-Quip recommends daily visual inspections of high-pressure pumps for leaks, abnormal noise or vibration, odd pressure readings, and temperature spikes. BHS Bearings suggests monthly visual inspection of compressor bearings, along with routine lubrication checks and vibration measurements.

In a home or small building, you can scale that down to quick monthly check-ins when the pump is running. Listen for changes in sound from normal, feel for increased vibration and heat, and look for leaks, rust, or discoloration around seals and housings. PlumbingSupply’s Myers pump guidance adds that persistent wet spots around the pump or basin, as well as leaks at check valves, can indicate deeper mechanical issues. That matters for bearing wear because leaks often reflect excessive shaft movement or seal damage, which can be both a cause and an effect of distorted bearings.

When the pump is off and safely locked out, a gentle manual rotation test can sometimes reveal early roughness. NSK describes how small ball bearings in machinery are checked for smoothness by rotating the outer ring and feeling for abnormal resistance or noise. You will not always be able to access the bearing directly in a sealed home pump, but anything that used to spin freely by hand and now feels gritty or uneven merits attention from a technician.

Instrumented Monitoring for Critical or Smart Systems

For critical pumps or larger residential complexes, it can make sense to add more formal condition monitoring. Maintenance World defines condition-based monitoring as using measured equipment condition data to detect failures early enough to plan and schedule repairs instead of reacting to breakdowns. They recommend on-the-run, instrument-based methods like vibration analysis, shock pulse monitoring, temperature readings, and wear-particle analysis for bearings. Samotics goes a step further for submersible and hard-to-access pumps, highlighting Electrical Signature Analysis, which listens to the motor’s electrical behavior to detect mechanical problems such as bearing wear, misalignment, and flow irregularities.

WD Bearing Group advocates pairing vibration analysis with thermal imaging to catch early signs of wear, misalignment, or lubrication breakdown in mud pump bearings. Cornell Pump similarly endorses temperature and vibration monitoring for municipal pumps as part of condition-based programs. Even if your home system does not justify continuous instrumentation, these methods are valuable tools for your installer or service provider. For example, during an annual service visit, a technician might quickly measure vibration at bearing locations and scan bearing housings with a thermal camera to compare against previous baselines, much like the monthly vibration and two-week bearing checks described in Maintenance World’s fan case study.

One important nuance from Maintenance World is that condition monitoring only improves reliability if you act on the data. It does not extend the physical life of bearings; instead, it gives you time to plan downtime when early signs of failure appear. That means if your pump’s controller or service reports show rising vibration levels or temperatures, the right response is to schedule bearing inspection or replacement while the pump is still running, not to ignore the trend until a failure forces your hand.

Root Causes of Bearing Wear You Can Control

Identifying wear is only half the story. To keep your pressure pump in top condition, you also need to understand what causes that wear and which levers you can realistically pull in a home hydration system. Across sources like Pumps & Systems, WD Bearing Group, BHS Bearings, Cornell Pump, and Maintenance World, four themes dominate: lubrication, contamination, alignment and loading, and operating conditions such as cavitation and dry running.

Lubrication: The Lifeblood of Bearings

Several sources agree that lubrication is the single biggest driver of bearing life. WD Bearing Group notes that improper lubrication is the dominant cause of mud pump bearing failures, estimating that roughly forty to seventy percent of failures stem from incorrect lubricant type, wrong intervals, or insufficient quantity. Samotics cites RKB data suggesting that around eighty percent of bearing failures in pumps are tied to improper lubrication that leads to overheating. Pumps & Systems explains that lubrication’s job is to create a thin oil film that reduces friction, carries away heat, prevents rust, and keeps contaminants out.

For your home pressure pump, that translates into three practical habits. First, use the lubricant type and viscosity recommended in the pump’s manual, and avoid mixing greases or oils unless the manufacturer confirms compatibility. Pumps & Systems points out that mixing incompatible lubricants can be as damaging as under-lubrication. Second, respect the suggested intervals rather than waiting for noise or heat; as BHS Bearings emphasizes, effective lubrication management includes checking lubricant condition as well as level. Third, avoid both extremes: over-lubrication can cause churning, heat, and seal damage, while under-lubrication leaves surfaces exposed.

Industrial compressor guidance from BHS Bearings suggests lubrication checks every 500 operating hours. If your home booster pump runs about two hours per day, that is close to one check per year in equivalent terms. This does not replace the manufacturer’s schedule, but it illustrates how even modest daily run times add up and why “set and forget” is not a good strategy for bearings.

Contamination and Cleanliness

Contamination is the second major culprit, often working hand in hand with poor lubrication. Maintenance World highlights that bearing clearances are so small that dust, tobacco smoke, and fingerprint residues are as large or larger than the gaps the rolling elements rely on. Once those particles enter the bearing, they break the oil film and act like abrasive grit, accelerating wear. WD Bearing Group quantifies this effect in mud pumps, attributing about thirty percent of bearing failures to contamination from mud and fine particulates.

Pumps & Systems adds that environmental factors such as dust, dirt, water, and aggressive media require robust seals and careful design choices. NSK’s cleaning and inspection instructions reinforce the same message in reverse: even during maintenance, bearings must be handled with very clean oil baths, gentle brushing, and no rotation while foreign material is present to avoid scoring the raceways.

For a home hydration system, contamination control mostly comes down to discipline. Store lubricants in closed, clean containers away from dust and chemicals. Keep pump rooms or under-sink cabinets tidy rather than using them as catchalls for bags of soil, paint, or corrosive cleaners that can off-gas or shed particles. If your pump is in a garage or utility space where airborne dust and moisture are common, consider simple protective covers recommended by WD Bearing Group for harsh environments, making sure they still allow adequate ventilation. The goal is to keep the environment around your bearings as clean and dry as reasonably possible, consistent with the tight clearances they rely on.

Alignment, Vibration, and Operating Conditions

The third cluster covers how the pump is installed and operated. FCX Performance describes proper installation as one of three pillars of pump reliability, emphasizing a solid foundation, good suction piping design, and accurate shaft alignment to limit vibration and wear on bearings and seals. Cornell Pump echoes that proper alignment between pump and driver, along with balanced impellers, reduces vibration and premature failure. WD Bearing Group notes that misalignment and overload beyond rated capacity lead to higher friction, vibration, and structural fatigue in bearings.

Operating conditions matter just as much. Iwaki’s technical glossary explains cavitation as the formation and collapse of vapor bubbles when suction pressure drops below the liquid’s vapor pressure. Those implosions damage internal components and reduce efficiency, so maintaining adequate suction head and avoiding obstructions are key. Samotics advises preventing dry running and ensuring correct startup and shutdown procedures, while McLanahan warns that operating significantly away from a pump’s best efficiency point, especially at very low flows, increases wear and reduces performance.

At home, that means several actionable habits. Make sure any suction strainers or filters on your pump are kept clean so the pump is not starved of water, which can trigger cavitation. Avoid running the pump against a closed discharge valve; FCX Performance specifically calls out closed suction or discharge valves as dangerous conditions in industrial pumps. After service, double-check alignment if the pump or motor has been moved, and consider having a professional verify alignment with proper tools whenever major components such as bearings or seals are replaced. Reducing unnecessary cycling also matters: the Myers pump article shows that correct pressure switch settings and tank air charge help prevent excessive on–off sequences, which otherwise accumulate more start-stop stress cycles on bearings than necessary.

Deciding When to Monitor, Repair, or Replace

Even with good habits, all mechanical parts eventually wear. The question then becomes how to decide between continued monitoring, bearing replacement, or full pump replacement. NSK’s bearing inspection and reuse criteria are helpful here, even though they are written for industrial technicians. They advise that any bearing with cracks, flaking, heavy smearing, severely worn cages, rust or scoring on raceways or rolling elements, noticeable impact marks, significant creep on the bore, heat discoloration, or serious seal damage should not be reused. Cornell Pump adds that it is smart to replace bearings before they damage the shaft, because a worn shaft is much more expensive and time-consuming to repair than a set of bearings.

In a home setting, you can think of three broad stages. In the early stage, you might notice subtle noise changes, slightly higher vibration by feel, or a modest temperature increase at the housing, but the pump still meets pressure and flow expectations. Maintenance World would view this as the ideal time for condition-based planning: schedule an inspection or service visit, and consider asking the technician to collect vibration or thermal data to build a baseline. You continue operating but with heightened awareness and a plan.

In the middle stage, symptoms become harder to ignore. The pump may grow noticeably louder, vibration might transmit through floors or cabinetry, and the housing could become uncomfortably hot during routine operation. You may also see efficiency changes, such as longer run times or a higher utility bill for the same water use, which McLanahan associates with internal wear. At this point, continued operation moves into a higher-risk zone. A technician will often recommend bearing replacement and a thorough inspection of seals, shaft surfaces, and alignment. The key is to act before the bearing fails catastrophically and damages the shaft, impeller, or housing.

In the late stage, you or your service provider may find clear signs of severe damage during inspection: flaking, heavy scoring, discoloration, or loose cages, just as NSK lists. The pump may have already tripped on overload, seized, or leaked. WD Bearing Group’s guidance for emergency repairs emphasizes rapid inspection of bearings and housings, restoration of proper lubrication, and replacement with high-quality spares to keep downtime and collateral damage to a minimum. For older or lower-cost residential pumps, you may find that replacing the entire unit is more economical than rebuilding, especially if multiple components show advanced wear. Either way, allowing operation to continue at this stage risks sudden loss of pressure, unexpected leaks, and extended downtime for your water system.

How Bearing Health Supports Water Wellness

It is easy to see bearing care as a purely mechanical concern, but in a home hydration system it directly supports your water wellness goals. Hydro-Quip shows how regular maintenance on high-pressure pumps maximizes equipment longevity, improves efficiency, reduces downtime, and enhances safety. Cornell Pump notes that municipal pumps can serve communities for decades when maintained proactively. Those same principles apply, scaled down, to the pump that feeds your filters and hydration stations.

Stable, low-vibration operation keeps your system quiet and unobtrusive, which matters when pumps sit under kitchen counters or near living spaces. Consistent pressure supports your filtration performance; many filter housings and membranes are designed to operate within specific pressure ranges, and fluctuations from a struggling pump can reduce effectiveness or stress components prematurely. Preventing leaks by catching bearing-related seal issues early protects your home from moisture damage and keeps your water pathway predictable, which is especially important when you value the safety and taste of every glass you pour.

Most importantly, paying attention to bearing wear reflects a mindset of stewardship over the whole hydration system. Rather than reacting to failures, you are partnering with your installer or maintenance provider to anticipate and prevent problems. That proactive approach is exactly what industrial condition-monitoring experts advocate and what keeps critical pumps in continuous service. Applied at home, it translates into more reliable access to clean, refreshing water and fewer disruptions to your daily routines.

FAQ: Bearing Wear in Home Pressure Pumps

Q: My pressure pump still works but has gotten noticeably louder. Is it safe to keep using it? Noise alone does not prove that bearings are failing, but BHS Bearings, McLanahan, and Pumps & Systems all emphasize that increasing grinding or humming noise and rising vibration are classic early symptoms of bearing wear, misalignment, or flow problems. Continuing to operate through those signs may allow minor wear to progress into shaft damage, seal failure, or a complete breakdown. A reasonable approach is to continue using the pump for essential needs while promptly scheduling an inspection. Asking a technician to check vibration, temperature, and alignment, and to listen for characteristic bearing sounds, can clarify whether you are still in the early stage where a planned repair makes sense or closer to a critical failure.

Q: How often should I think about bearing checks in a residential system? Industrial guidance varies by duty and environment. BHS Bearings mentions monthly visual inspections and lubrication checks every 500 operating hours for compressor bearings, while Hydro-Quip and Cornell Pump recommend structured schedules ranging from daily visual checks to annual performance testing for high-pressure and municipal pumps. For a home system that may run fewer hours and see gentler conditions, a practical adaptation is to perform a quick visual, sound, and touch check every month or two and to have a more thorough inspection performed annually or whenever symptoms appear. The most important rule is to follow the maintenance intervals and lubrication instructions in your pump’s manual, then treat industrial recommendations as useful context rather than rigid rules.

Q: Will smart monitors or apps replace the need to listen and look at the pump? Advanced condition-monitoring tools are powerful, but experts like Maintenance World and Samotics are clear that instruments complement rather than replace basic inspection. Condition-based monitoring only improves reliability if you act on what it tells you, and many early warning signs—such as a new rattle, a hot spot you can feel, or a slight leak at a seal—are still easiest to catch with your senses during a simple walk-by. If your system includes monitoring of pressure, temperature, vibration, or power draw, use those trends the way industrial operators do: compare to established baselines and treat deviations as prompts to investigate. Combining smart data with regular human observation mirrors best practices in high-reliability plants and gives your home hydration system the same thoughtful care.

Closing Thoughts

Bearings may be hidden inside your pressure pump, but their condition has a direct impact on how quietly, efficiently, and reliably your smart hydration system serves you every day. By learning to recognize early signs of wear, understanding the roles of lubrication, cleanliness, and alignment, and partnering with qualified professionals when intervention is needed, you turn a potential weak point into a strength. In my experience, the homes and facilities that enjoy the most consistent, high-quality water are not the ones with the most complex equipment; they are the ones where small components like bearings receive the steady, science-backed attention they deserve.

References

- https://energy.gov/sites/prod/files/2014/05/f16/pump.pdf

- https://naxja.org/threads/bearing-wear-and-oil-pressure-educate-me-please.87992/

- https://www.plumbingsupplyandmore.com/how-to-identify-address-signs-of-wear-myers-pump?srsltid=AfmBOooaltkGXpGkZzyIyF1NRT4kft4VN70Dh_NamqrmbHYOezJkZ-26

- https://www.pumpsandsystems.com/bearing-failure-analysis

- https://www.bhsbearings.com/news/how-to-detect-early-wear-in-compressor-bearings.html

- https://www.cornellpump.com/top-maintenance-practices-for-long-term-life-of-municipal-pumps/

- https://www.hydro-quip.com/post/the-importance-of-regular-maintenance-for-high-pressure-pumps

- https://iwakiamerica.com/technical-information-guide-glossary/

- https://www.mclanahan.com/blog/15-signs-of-wear-in-your-aggregate-slurry-pump

- https://nyzbearing.com/the-ultimate-guide-to-measuring-bearing-clearance/

Share:

Understanding Why Your RO System Sometimes Refuses to Operate

Understanding Why Your Pump Starts But Lacks Pressure