Keeping stored water genuinely safe is about more than filters and lab tests. The tank itself—its material, coating, and how it is maintained—quietly shapes the microbiological quality of every glass you pour. Over the last decade, silver ion antibacterial technology has moved from lab papers into real-world water storage tanks, promising cleaner surfaces and less biofilm.

As a smart hydration specialist, I spend a lot of time bridging what coating science says in controlled studies and what actually happens in a tank that lives on a hot rooftop or in a dusty yard. When people consider antimicrobial tanks, the same question always comes up: how long do those silver ion coatings really last?

The honest, science-backed answer is more nuanced than a single number of years. Let’s unpack what the research and real-world tank data actually show, and how you can get the longest, healthiest life out of a silver-ion antibacterial tank.

What Exactly Is a Silver Ion Antibacterial Coating?

In water storage, “antimicrobial coating” is a broad term. According to technical guidance on water storage systems, antimicrobial coatings are protective layers on tank surfaces that inhibit the growth of microorganisms such as bacteria, algae, fungi, and sometimes viruses. They do this either by making it hard for microbes to stick in the first place, or by killing or disabling them when they contact the surface.

Silver ion technology is one of the most widely adopted antimicrobial approaches for plastic and polymer tanks. Manufacturers such as BioCote, Ultra-Fresh, and IPNR Endura embed silver-based antimicrobial agents into the polymer inner layer during manufacturing, rather than painting something on later. That inner layer is food-grade, often made from 100 percent virgin plastic, and is tested to be safe for contact with potable water.

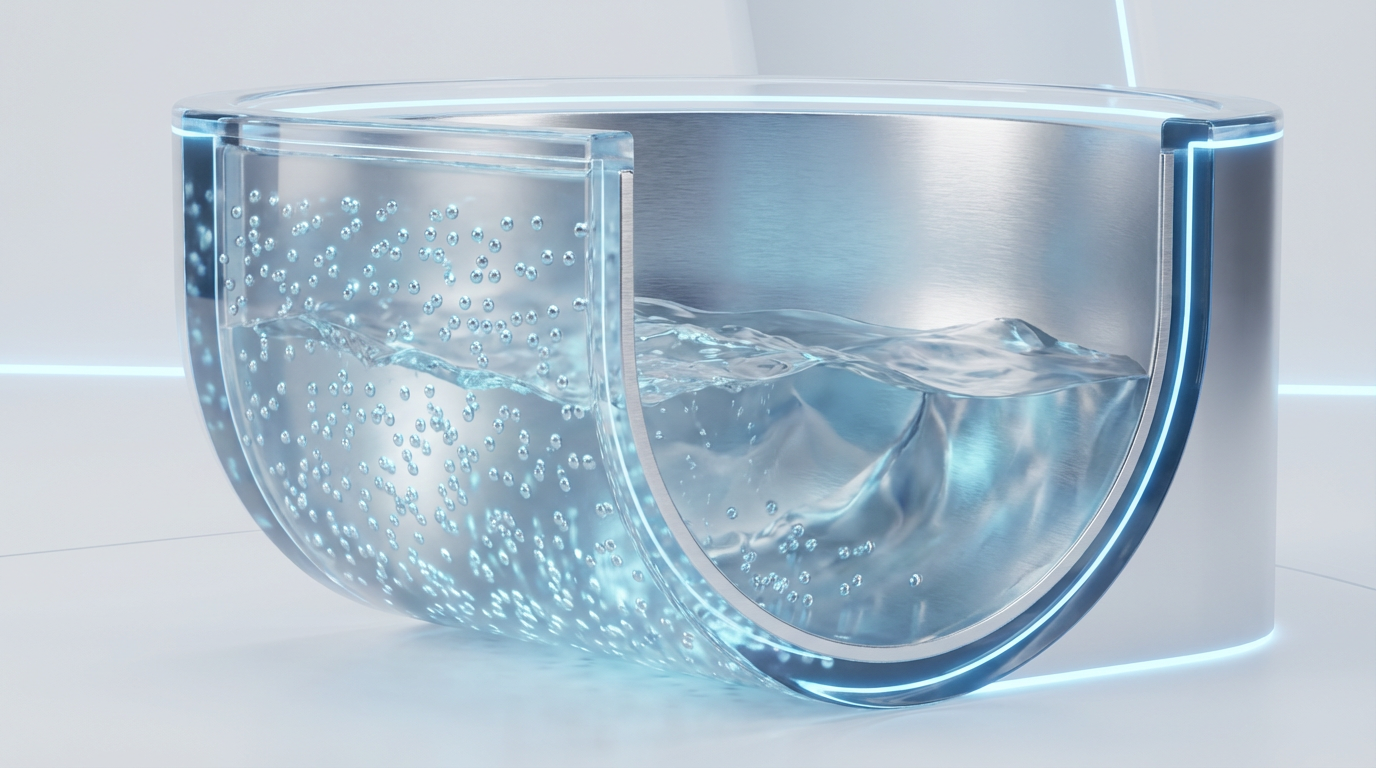

The Ashirvad–BioCote partnership on antimicrobial tanks is a good example. Their tanks use a multilayer structure. The inner layer, which touches the water, contains silver ion technology validated by the JIS Z2801 antimicrobial test method. A blackout middle layer blocks sunlight and helps prevent algae, and a UV-stable outer layer protects the tank shell from sun damage. The inner surface is typically white with a subtle tint that makes it easier to see water level and clarity.

A similar approach is described by Ultra-Fresh and Microban for plastic and fiberglass tanks: antimicrobial additives are compounded directly into the tank material. IPNR Endura describes these systems as polymer tanks with built-in antimicrobial agents that continuously inhibit bacteria, algae, and fungi in moist tank environments and help limit biofilm formation.

This “built-in” design is important for longevity. It means the antimicrobial technology is part of the tank wall itself, not a thin film that can easily wash off.

What Do We Actually Know About Their Durability?

Marketing language often talks about “long-lasting antimicrobial protection,” but as a water quality professional I look for evidence: warranties, independent test methods, and what we know about coating life in real tanks.

Several pieces of data from reputable sources help frame realistic expectations.

First, tank and coating system lifecycles. Traditional protective coating specialists, including companies that work on large municipal water tanks, consistently report that high-quality interior coatings are designed for long service intervals rather than constant replacement. Guidance from experienced tank refurbishment providers indicates that many steel storage tanks are completely recoated roughly every 10 to 15 years to maintain corrosion protection, provided maintenance is done well in between. Interior lining specialists such as COVAC describe premium potable-water linings that can extend a tank’s life by decades, and they back their work with guarantees of at least 10 years when correctly applied and maintained.

Second, antimicrobial tank warranties. Ashirvad’s antimicrobial plastic tanks, which include an inner silver-ion layer, are sold with a 10-year warranty on the tank. The warranty is for structural performance rather than a separate “expiration date” on the silver, but it does tell you that the manufacturer expects the multilayer structure—including the inner antimicrobial surface—to stay intact under normal conditions for about a decade.

Third, laboratory evidence of antibacterial durability. Ultra-Fresh reports testing antimicrobial-treated and untreated tank materials using ISO 22196 and ISO 20743 methods with Escherichia coli. After a 24-hour incubation at body-like temperatures, the untreated plastic showed an increase from roughly 50,000 to nearly 500,000 bacterial cells. The antimicrobial-treated sample, by contrast, showed around 99.9 percent fewer bacteria after the same period. While this test is short-term, it demonstrates that the built-in additive remains active under repeated wet exposure and does not wash off in the first day of use.

Independent research on antimicrobial polymer coatings, including reviews in journals such as Polymers and applications described for construction materials, supports this picture. Coatings with embedded silver nanoparticles and other antimicrobial agents are designed for durable performance, not single-use disinfection. Studies describe them as providing long-term antibacterial activity, and some advanced coatings combine anti-adhesive surfaces with “contact killing” to block biofilm over multi-week experiments.

Finally, broader tank-coating practice matters. Municipal and industrial tank maintenance guidelines from providers such as Pittsburg Tank & Tower Group and Cunningham emphasize that when surface preparation, coating selection, curing, and maintenance are handled correctly, coating systems provide reliable protection across many years of service. Timely inspections, cleaning, and touch-ups are what turn a theoretically durable system into a long-lived one.

Taken together, the evidence supports a practical conclusion.

Silver ion antibacterial protection in tanks is designed as a multi-year, embedded feature that should last as long as the inner surface remains structurally sound and not heavily worn, rather than a short-lived “spray” that stops working in a few months. However, there is no single universal number of years published for all tanks, because performance depends strongly on tank design, operating conditions, and maintenance.

How Silver Ion Antimicrobial Systems Are Built Into Tanks

To understand why silver ion protection can be long-lived, it helps to look at how these layers are engineered.

In many modern polymer tanks, the antimicrobial agents are mixed into the plastic resin before the tank is molded. Tank manufacturers describe this as adding antimicrobial technology during the masterbatch or compounding step. The result is a plastic inner layer in which the silver-containing additive is distributed throughout the material.

Because the antimicrobial agent is inside the plastic matrix, it does not simply sit on the surface as a fragile film. When the very top of the surface wears microscopically from cleaning or contact, new material with active antimicrobial agent is exposed. This is fundamentally different from a painted-on coating where the functional ingredient may be concentrated in only a thin top layer.

This integrated structure is backed by mechanical design. Antimicrobial polymer tanks are typically described as lightweight but sturdy, with ribbed walls and UV-stable outer shells to resist cracking under sunlight and temperature swings. The Ashirvad antimicrobial tank range, for example, uses a multi-ribbed body, UV-stable outer layer, and threaded UV-stable lid designed to keep out debris and block sunlight from entering through the top. All of this helps protect the inner antimicrobial layer from physical and environmental stress, indirectly supporting its longevity.

In engineering terms, the silver ion functionality lasts as long as the inner layer remains largely intact, not chalked, heavily scratched, or delaminated.

Antimicrobial Coatings Versus Conventional Linings

Silver ion antimicrobial technology is not a replacement for conventional tank linings; it is an enhancement. It helps to put these systems side by side.

Feature or focus |

Silver-ion antimicrobial inner layer |

Standard potable tank lining (no silver) |

External protective paint system |

Main job |

Inhibit microbial growth and biofilm on inner surfaces while remaining food-grade |

Provide a smooth, non-porous barrier between stored water and tank material, preventing corrosion and contamination |

Protect external shell against weather, UV, and corrosion |

Where it lives |

Molded into the inner plastic layer or applied as an antimicrobial coating |

Epoxy, polyurethane, or cementitious lining applied to metal or concrete interiors |

Industrial paints and coatings on outside of tank |

Antimicrobial action |

Continuous inhibition of bacteria, algae, and fungi on the surface, reducing odors, staining, and deterioration |

Relies on smooth, cleanable surface and disinfection rather than built-in antimicrobial agents |

Typically none; focuses on corrosion protection |

Design lifetime signals |

Embedded in layer that may be covered by tank warranty; life linked to integrity of inner surface |

Often backed by 10-year or similar guarantees when properly applied and maintained |

External paint often targeted for full repainting every 10–15 years in many municipal programs |

Maintenance needs |

Still requires annual cleaning and periodic disinfection; antimicrobial layer complements hygiene practices |

Same cleaning and disinfection needs; surface must be protected from aggressive abrasion |

Visual inspections, touch-ups, and periodic full repainting to control corrosion |

From a water wellness perspective, the key advantage of silver ion layers is that they make it harder for microbes to gain a foothold between cleanings. They do not sterilize water or replace filtration or chlorine, but they change what lives on the plastic and how quickly visible slime and odors develop.

What The Research Says About Antimicrobial Durability

Several strands of research are relevant when we talk about how long antimicrobial coatings stay effective in wet conditions.

Studies on antimicrobial water filters highlight how quickly biofilms normally form on untreated plastics. For instance, research on deep-bed polypropylene filters notes that hydrophobic polymer fibers, about five micrometers in diameter with around 90 percent porosity, readily accumulate bacteria that grow into biofilm and progressively clog the filter, typically forcing replacement in about six to twelve months. Conventional strategies that only adjust water chemistry or surface roughness often struggle to fully prevent biofilms at high biomass loads.

To address this, researchers have developed coatings that combine anti-adhesive behavior with antibacterial action. One example uses a sulfonated pentablock copolymer to coat polypropylene fibers. Over a 20-day incubation with Pseudomonas aeruginosa in water, the coated samples remained visually free of bacterial aggregates, while unmodified fibers showed obvious bacterial build-up. The authors attribute this to smoother, more hydrophilic, negatively charged surfaces that increase shear forces and electrostatic repulsion, preventing stable attachment.

Although that particular study did not use silver, it illustrates a principle that also applies to silver ion technologies: when antimicrobial agents are incorporated into durable polymer matrices, they can meaningfully inhibit biofilm over extended wet exposure rather than just in the first day.

The construction materials literature adds a complementary perspective. A 2024 study on antibacterial durability of waterproof coatings with different base materials, summarized in a construction materials journal, points out that diverse nanomaterials and antimicrobial additives—from silver nanoparticles to metal oxides and MXene-based systems—are being embedded into waterborne polyurethane, acrylic, and other binders. The reference list in that work spans more than a decade of research, underscoring that durable antimicrobial coatings are an active area of engineering for harsh, wet environments such as sewers, pavements, and building envelopes.

In polymer foam and coating studies, silver nanoparticles have been shown to provide sustained antibacterial performance when locked into rubber or polyurethane matrices. Reviews of polymeric antimicrobial coatings emphasize that integrating antimicrobial agents directly into the coating binder produces longer-lasting protection than simply relying on surface treatments.

For household and community water tanks, Microban, Ultra-Fresh, and similar technology providers echo the same theme. Embedded antimicrobial additives are framed as a long-term protective barrier that reduces microbial infestation and keeps tank surfaces cleaner between routine sanitation events. They stress, however, that routine annual cleaning and disinfection are still imperative and that antimicrobial tanks are an additional defense, not a replacement for hygiene.

The takeaway from this body of evidence is that antimicrobial functionality is designed to persist over many wet cycles and cleaning events, provided the underlying matrix is robust.

It is not meant as a short-lived coating that disappears with the first disinfection.

Factors That Control How Long Silver Ion Protection Really Lasts

Even the best-engineered antimicrobial coating can underperform if the tank environment is harsh or maintenance is neglected. From a practical standpoint, five groups of factors have the biggest influence on how long silver ion protection remains meaningfully effective.

Condition of the Inner Surface

The antimicrobial layer works at the interface between plastic and water. If that surface becomes heavily scratched, chalked, or physically damaged, the coating may lose its smoothness and become harder to clean. Rough, cracked areas are natural harbors for biofilm, even if antimicrobial agents are still present deeper in the plastic.

Interior lining specialists highlight this in the context of non-antimicrobial coatings as well. Excessive peeling, visible corrosion, or persistent staining are clear indicators that an interior surface is no longer performing as designed and may require professional relining or tank replacement.

For silver ion tanks, the principle is similar. As long as the inner wall appears smooth, intact, and free from deep gouges, the antimicrobial system embedded in that wall can continue to play its role.

Sunlight, Heat, and Weather

UV radiation and thermal cycling slowly degrade polymers. That is why antimicrobial tanks are built with UV-stable outer layers and blackout middle layers. The outer shell takes the brunt of the UV, while the inner antimicrobial layer is shielded from direct sunlight.

If a tank is installed in conditions that exceed its design—such as extreme, prolonged exposure on a rooftop without shading, or near industrial heat sources—the outer layers may deteriorate faster, with potential knock-on effects for the inner surface over time. Coating experts who work on municipal tanks emphasize that managing temperature swings and protecting against UV is critical to extending coating life.

Choosing tanks with UV-stable construction and installing them in shaded or well-ventilated locations helps the antimicrobial layer live up to its design potential.

Cleaning and Disinfection Practices

There is a sweet spot in cleaning. Too little cleaning, and biofilm overwhelms any antimicrobial surface; too aggressive cleaning, and the surface can be mechanically or chemically damaged.

Multiple reputable sources converge on yearly cleaning as a baseline for water storage tanks. COVAC describes annual cleaning as imperative for controlling Legionella and other waterborne bacteria. Flexi-Liner emphasizes that at least once-a-year cleaning improves longevity, efficiency, and cost-effectiveness. Ultra-Fresh notes that various government agencies recommend cleaning storage tanks at least once per year and additionally after significant events, such as nearby construction, flooding, or long periods of non-use.

Disinfection is typically done using chlorine-based solutions. For example, professional cold-water tank cleaning regimes in the UK use shock chlorination around 50 milligrams per liter free chlorine for at least an hour, followed by flushing and microbiological testing after about 48 hours. Household cistern guidance from Ultra-Fresh describes filling the tank and dosing with household bleach to approximately 50 milligrams per liter, which is roughly achieved by adding about 17 fluid ounces of chlorine to around 120 gallons of water, letting it stand at least six hours, and then flushing until the odor dissipates.

Well-chosen cleaning and disinfection regimens like these are compatible with robust antimicrobial plastics. What you want to avoid are abrasive tools such as metal scrapers that gouge the surface, or unapproved chemicals that can attack the plastic. High-pressure fresh water, soft brushes, and approved disinfectants are the safer route.

Water Quality and Biofilm Pressure

Stored water is rarely sterile, even if it originates from a treated municipal system. Guidelines summarized by Microban and Ultra-Fresh emphasize that stored water is vulnerable to bacteria, algae, pH shifts, and mineral build-up, especially when chlorine residual is lost or water sits for long periods.

In systems where incoming water quality is poor, or storage times are long, the microbial load on tank walls is higher. Antimicrobial surfaces still reduce colonization and help keep tanks cleaner, but their apparent “effective life” may feel shorter because they are constantly fighting heavy biofilm pressure.

Regular water quality testing helps you stay ahead of this. Several tank coating providers recommend microbial testing for organisms such as Legionella at least every six months in higher risk settings, combined with temperature and visual monitoring.

System Design and Turnover

Tank design and how it is operated influence how well any coating, antimicrobial or not, performs. Cold water tank standards point out that stagnation and warm temperatures are major risk factors. Good design includes keeping cold water below about 68°F, avoiding dead legs in piping, ensuring adequate turnover, and using mixing or recirculation where needed.

In practice, a silver ion coating in a well-designed system with regular turnover and cool temperatures is under much less stress than a similar coating in a warm, stagnant rooftop tank. Thoughtful design and operation are therefore part of preserving antimicrobial performance.

Practical Timeframes For Homeowners and Facility Managers

Putting all of this together, how should you think about the lifespan of silver ion antibacterial tanks in a home or light commercial hydration system?

Short term, in the first year, the priority is proper commissioning. That means filling and disinfecting the tank after installation, flushing until disinfectant odor is gone, and then confirming taste and clarity. Silver ion additives are there from day one and, as laboratory tests show, can significantly reduce bacterial growth on surfaces within the first 24 hours of use.

Over the medium term, roughly years two through ten for many polymer antimicrobial tanks, the system is in its design window. During this period, aim to clean the tank at least once a year, more frequently if water testing or visual inspection suggests problems. Combine cleaning with a suitable disinfection step, and address any small issues early, such as worn gaskets or loose lids that could admit insects or debris. Embedded antimicrobial technology during this period helps surfaces stay cleaner between cleanings, makes biofilm easier to remove, and reduces odors and staining.

Over the long term, around the decade mark and beyond, the key question is the condition of the tank itself. Manufacturers like Ashirvad provide a 10-year warranty on antimicrobial tanks, and lining specialists often guarantee their potable linings for a similar timeframe. Exterior coating experts frequently recommend major recoating cycles at 10 to 15 years for steel tanks. Those numbers do not mean the tank or the antimicrobial layer suddenly fails at year eleven, but they are sensible checkpoints.

Around this age, it is wise to arrange a thorough tank inspection. For metal or large concrete tanks, that may involve professional divers, remotely operated vehicles, or drained-entry inspections that evaluate internal linings, wall thickness, and roof condition. For polymer household tanks, it involves draining, cleaning, and a careful inspection for cracks, chalking, or significant surface degradation. If the inner antimicrobial surface looks and feels sound and water quality is good, there is usually no reason to assume the antibacterial functionality has disappeared.

If, however, you see persistent staining that does not respond to cleaning, cracks, or interior surfaces that have visibly deteriorated, it may be time to consider tank replacement or professional relining. At that point, the limiting factor is structural and hygienic integrity of the surface, not solely the chemistry of the silver additive.

Pros and Cons of Silver Ion Antibacterial Tanks

From a water wellness standpoint, silver ion tanks have clear upsides and some trade-offs compared with standard storage.

On the positive side, integrating antimicrobial agents into the tank wall reduces bacterial growth that causes odors, staining, and material degradation. Ultra-Fresh’s test results showing roughly 99.9 percent fewer E. coli cells on treated plastic after 24 hours underscore how significant this difference can be. In practice, that translates into cleaner-looking tank walls and less smell between cleanings.

Antimicrobial tanks also support sustainability goals. IPNR Endura notes that polymer tanks with built-in antimicrobial agents are typically recyclable, require less frequent heavy chemical cleaning, and reduce long-term maintenance. That aligns with the broader push toward water reuse, rainwater harvesting, and household cisterns described by Ultra-Fresh and the World Health Organization’s household water treatment and safe storage strategy.

On the limitations side, antimicrobial technology is not a license to ignore maintenance. The World Health Organization’s definition of safe drinking water still hinges on microbial, chemical, and physical parameters, and the presence of silver ions in the tank wall does not address issues like contaminated source water, failing filters, or chemical pollutants. Multiple sources stress that annual cleaning and disinfection remain imperative, even for antimicrobial tanks.

Another practical limitation is that the effective life of the technology is not usually stated as a simple year count. You must rely instead on tank warranties, general coating life data, and ongoing inspection and testing.

Finally, silver ion systems represent an added cost compared with the simplest storage tanks. Many facility operators, including those cited by Nexteel and Microban, justify this premium by pointing to lower maintenance, better hygiene, and reduced risk of waterborne disease, but the cost-benefit balance will differ for each household or site.

How To Help Your Silver Ion Tank Coating Last

From a smart hydration system perspective, there are several habits that make a noticeable difference to the lifespan and effectiveness of silver ion tanks.

Choose the right tank for the job, starting with food-grade, certified materials explicitly designed for potable water. Ensure the inner layer is marketed as antimicrobial and has evidence of testing, such as JIS Z2801 or ISO 22196, and confirm that the tank meets local regulatory expectations for drinking water use.

Install tanks thoughtfully. Place them where they are protected from unnecessary heating and direct sun exposure, and use UV-stable lids that fit tightly to keep debris, insects, and animal droppings out. Connect tanks to your filtration and distribution systems with attention to avoiding dead-end pipe sections where water can stagnate.

Commit to a routine annual cleaning and disinfection cycle, even though you have antimicrobial technology working for you. Drain the tank completely, remove sediment and debris using high-pressure fresh water and soft tools, inspect for cracks or leaks around hatches and vents, and then disinfect with an appropriate chlorine dose and contact time. After disinfection, flush until the water no longer smells strongly of chlorine.

Monitor water quality regularly. Use simple test kits or professional services to check for bacteria and key chemical parameters at least every six months in higher-risk situations. If you notice recurrent problems, do not rely on the antimicrobial tank alone; investigate upstream filtration, possible contamination points, and operating temperatures.

Finally, treat tanks as part of an integrated hydration system. Antimicrobial surfaces complement but do not replace well-designed filtration, appropriate disinfectant use, and good plumbing practices. As systems age, be prepared to refurbish or replace components based on condition rather than waiting for a failure.

Brief FAQ

Does a silver ion tank mean I can skip chlorination or filtration?

No. Silver ion technology is designed to inhibit microbial growth on tank surfaces and reduce biofilm, odors, and staining. It does not replace source water treatment, filtration, or appropriate disinfectant levels recommended by public health agencies.

Will the silver from a tank leach into my drinking water?

Antimicrobial tanks intended for potable use are formulated to be food-grade and compliant with relevant safety standards, meaning they are tested so they do not release harmful levels of substances into water during long-term contact. Always look for tanks that are explicitly labeled as suitable for drinking water and backed by recognized certification.

Is there a point where the silver ion coating simply stops working?

Manufacturers do not usually publish a simple expiration date for silver ion performance. Instead, the practical endpoint is when the inner tank surface is no longer in good condition—when it is cracked, heavily worn, or no longer cleanable. If you maintain the tank, protect it from excessive UV and heat, and follow inspection and cleaning guidance, the antimicrobial benefit is expected to last as long as the tank’s food-grade inner layer remains sound.

In my experience, the healthiest hydration setups treat silver ion technology as a quiet, always-on helper rather than a magic fix. Pair a well-chosen antimicrobial tank with smart design, routine cleaning, and regular water testing, and you give your household or facility the best chance at consistently safe, great-tasting water over the long haul.

References

- https://water.mecc.edu/courses/ENV110/lesson10_4b.htm

- https://pmc.ncbi.nlm.nih.gov/articles/PMC7664665/

- https://www.cunninghaminc.org/from-prep-to-cure-a-guide-to-long-lasting-tank-coatings/

- https://www.highperformancecoatings.org/resources/how-our-coatings-ensure-compliance-for-potable-water-tanks

- https://www.researchgate.net/publication/381972983_Study_on_Antibacterial_Durability_of_Waterproof_Coatings_with_Different_Base_Materials

- https://www.ultra-fresh.com/water-storage-tanks-with-antimicrobial-technology

- https://amtanks.com/why-regular-paint-systems-inspection-and-maintenance-are-essential-for-water-tank-protection/

- https://bluelockerdiving.com/water-tank-cleaning-and-inspection-services/

- https://www.covac.co.uk/blog/proactive-water-tank-maintenance-tips-to-prolong-the-life-of-your-tank

- https://www.ipnr-endura.com/blog/why-antimicrobial-tanks-are-the-future-of-safe-water-storage

Share:

Understanding the Importance of pH Range for RO Membrane Functionality

Understanding When and Why to Boost RO Pressure Toward 0.6 MPa (About 87 PSI)