As a smart hydration specialist, I spend a lot of time inside people’s water systems, from compact countertop filters to whole‑home treatment trains. Again and again, I see the same question come up when we talk about carbon-based filters: should you choose a solid carbon rod cartridge, or a granular activated carbon (GAC) bed?

Both are built on the same core science of activated carbon adsorption, yet they behave differently in real homes. Understanding those differences is one of the most practical ways to improve your family’s drinking water, protect health, and avoid wasting money on the wrong technology.

In this article, I will walk through how carbon rods and GAC work, what the research says about their efficiency, and how to match each option to your actual water quality and lifestyle. I will stay grounded in reputable technical sources, including the Water Quality Association, the Environmental Protection Agency, leading activated carbon manufacturers, and peer‑reviewed reviews of adsorption-based treatment, while translating that science into everyday decisions for your kitchen and whole house.

Adsorption 101: The Science Behind Both Technologies

Before comparing carbon rods and GAC, it helps to understand adsorption, because this is the shared mechanism that actually cleans your water.

In adsorption-based filtration, contaminants stick to the surface of a solid material rather than soaking into it. Think of dust clinging to a dry cloth instead of water soaking into a sponge. The contaminant is called the adsorbate, and the filter material is the adsorbent.

High surface area is absolutely crucial here. Activated carbon is processed so that it contains a network of microscopic pores. Researchers have measured surface areas of over about 32,000 square feet per gram of activated carbon, and even higher for some advanced lab materials. That is like unfolding a whole neighborhood of surface area into something that looks like a black grain of sand.

The more internal surface, the more space there is for contaminants to attach.

Technical reviews on adsorption-based remediation emphasize two main modes of adsorption. In physical adsorption, or physisorption, contaminants are held by relatively weak forces similar to static cling; in chemical adsorption, or chemisorption, stronger chemical bonds form on the carbon surface. Both can occur in real filters. Volatile organic compounds (VOCs), many taste and odor compounds, and disinfection by‑products often bind well through physical adsorption. Disinfectants such as chlorine and chloramine, and some heavy metals, can be captured partly through chemical reactions at the carbon surface, especially when the carbon is specially modified.

Whether you are looking at a carbon rod or a GAC tank, the core goal is the same: maximize contact between contaminated water and a very high‑surface‑area carbon network long enough for those adsorption processes to do their job.

Activated Carbon: A Shared Foundation

Carbon rods and GAC are not different elements; they are different formats of activated carbon. Understanding that shared foundation helps you see where they diverge.

Activated carbon is typically made from carbon‑rich materials such as coconut shells, bituminous coal, wood, or agricultural residues. These feedstocks are first carbonized, then “activated” at very high temperatures in the presence of steam, air, or certain chemicals, which opens up that intricate pore structure. Reviews of modern carbon-based adsorbents highlight that using waste biomass as feedstock can lower the life‑cycle environmental footprint, because it converts what would have been agricultural or industrial waste into a valuable adsorbent.

In water treatment, activated carbon is prized for its ability to remove a wide range of organic contaminants. A National Academies review of drinking water treatment found that granular activated carbon could significantly reduce many nonpolar and moderately polar organics, including pesticides, chlorinated solvents, and suspected carcinogens, often from the tens of parts‑per‑billion range down to near detection limits when systems are well designed. The Water Quality Association similarly notes that granular activated carbon is especially effective for free chlorine, many taste and odor compounds, many VOCs, various synthetic organics such as certain pesticides and herbicides, and some disinfection by‑products.

However, these same sources emphasize that standard activated carbon has important limitations. It does not significantly reduce hardness, most dissolved salts, nitrate, or fluoride, and it is not a stand‑alone disinfection step. Some heavy metals are removed only modestly unless the carbon is specially impregnated or combined with other media. Those realities apply to both GAC and carbon rods, because both rely on the same underlying adsorbent.

Carbon Rod Filters: Solid Blocks For Compact, Controlled Filtration

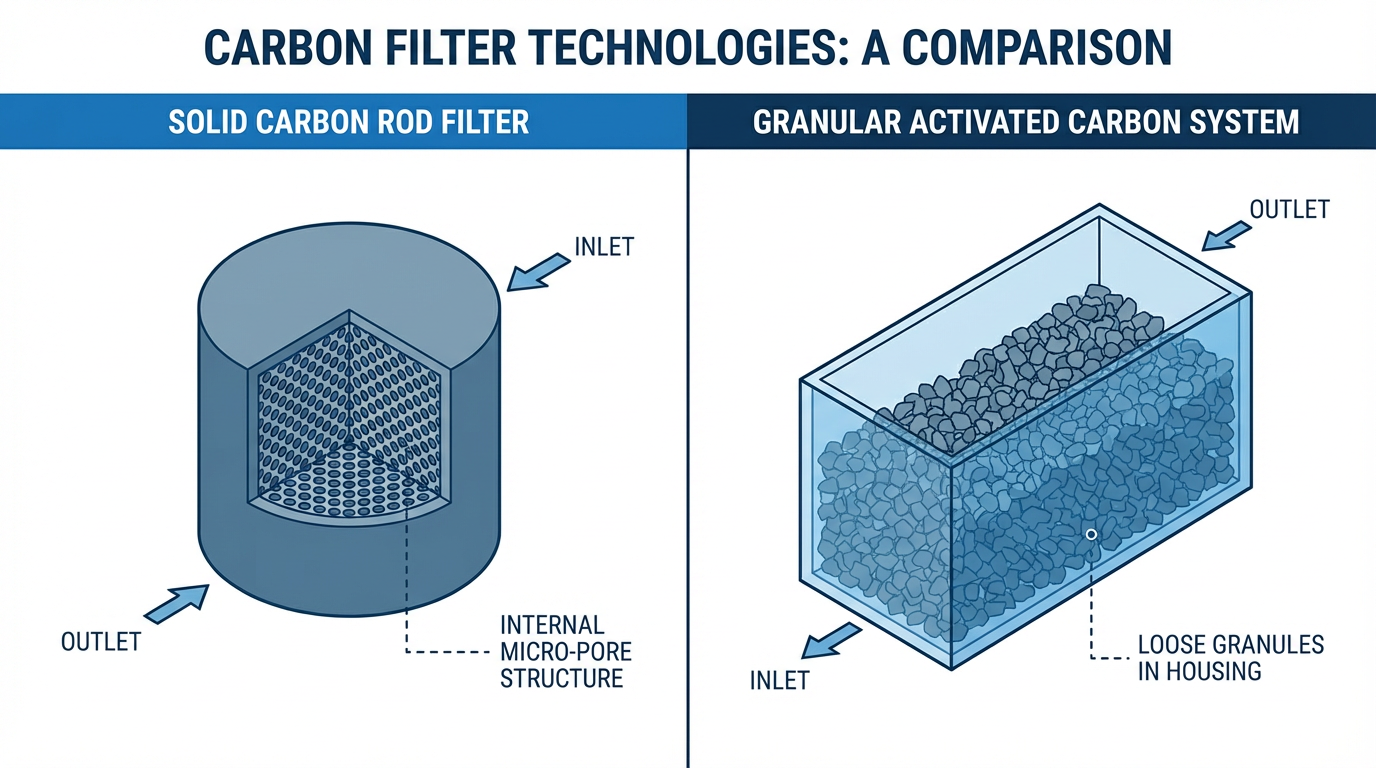

Carbon rod filters are built by mixing high‑quality activated carbon with binders and then shaping that mixture into solid rods under carefully controlled conditions. According to manufacturing descriptions from carbon rod equipment providers, the activated carbon chosen for these rods has a high specific surface area and a rich microporous structure, just like good GAC, but it is held together by a binder so it forms a stable block rather than loose granules.

There are two main forming methods. In extrusion molding, a continuous carbon rod with a fixed diameter is pushed through a die, with pressure and speed precisely controlled. Compression molding packs the carbon–binder mix into a mold, allowing very tight control over the rod’s density and dimensions. Both methods aim to maintain a porosity that supports strong adsorption while ensuring enough mechanical strength that the rod does not crack or crumble inside the cartridge.

Modern production lines for carbon rods use real‑time quality inspection. They monitor density and mechanical strength, and they run adsorption tests that simulate real filtration conditions. Only rods that meet strict standards for density uniformity, strength, and pollutant removal move forward to final assembly. That quality assurance matters in your home, because a cracked rod can create bypass channels where water zips through without meaningful contact, cutting real‑world efficiency.

In terms of performance focus, carbon rod filtration is widely used in household purifiers to improve taste, remove residual chlorine, strip out organic matter that contributes to odor, and reduce some heavy metals. The same technology scales up into commercial systems in offices, schools, and hospitals, and even into industrial water treatment for sectors like electronics and pharmaceuticals where water quality demands are high.

Research and development on carbon rods is moving toward smarter binders that let more of the activated carbon surface remain accessible without sacrificing structural strength, and toward chemical modification of the carbon to better adsorb emerging pollutants such as endocrine disruptors and some antibiotics. That means the best carbon rods today are already substantially more refined than early designs, and further gains in efficiency are realistic.

Granular Activated Carbon: Loose Media For Flexible, High‑Capacity Systems

Granular activated carbon is the same type of adsorbent, but instead of being locked into a single solid block, it is supplied as free-flowing granules. By definition, GAC is coarse enough to be retained on a 50‑mesh sieve, which translates to granules roughly a few hundred microns and larger, up into several millimeters depending on grade.

GAC has become the predominant process for removing organic matter, including micropollutants, in drinking water treatment plants. It is used in both point‑of‑use devices and point‑of‑entry systems, as well as in large municipal filters. Engineering references describe GAC adsorbers as very similar to rapid gravity or pressure filters: a deep bed of carbon, often around 8 to 10 feet thick in large systems, with water flowing downward or upward through the bed.

In these systems, a key design parameter is the empty bed contact time, which describes how long water stays in contact with carbon. For pesticides, engineering design guides often recommend contact times of roughly 15 to 30 minutes. For many disinfection by‑products and VOCs, about 10 minutes is common, and for systems where the focus is taste and odor, shorter contact times around that level can still be effective. These values come from pilot plant work and rapid small‑scale column tests that let engineers predict breakthrough time and carbon life.

The removal performance of GAC has been documented extensively. A review of activated carbon in drinking water treatment noted that, under well‑controlled conditions, GAC can reduce many target organics from tens of parts per billion down to at or near detection limits. EPA summaries of drinking water technologies report that GAC systems can achieve very high VOC removal, often approaching 99.9 percent in properly designed towers, with treated concentrations driven down to extremely low levels.

One of GAC’s biggest advantages over one‑time powdered carbon is reactivation. While powdered activated carbon is typically used once and discarded, granular activated carbon can be thermally reactivated and reused. Calgon Carbon and other manufacturers describe reactivation processes in which spent GAC is heated in steam or carbon dioxide at around 1,500°F. This drives off and destroys the adsorbed contaminants and restores most of the carbon’s capacity. Some mass is lost and capacity decreases gradually with each reactivation, but adding a fraction of fresh “virgin” carbon can keep performance near the original level. Puragen reports that reactivating GAC instead of manufacturing new carbon can reduce the carbon dioxide footprint of the medium by over 90 percent, which is a meaningful sustainability advantage, especially in large municipal and industrial applications.

The Water Quality Association notes that GAC performance in practice depends strongly on carbon type, bed depth, particle size, contact time, contaminant concentration, water temperature, and flow rate. Undersized or high‑flow systems deliver much less removal, regardless of the inherent quality of the carbon. Pre‑filtration to remove sediment helps prevent clogging and short‑circuiting of the bed, which would otherwise undermine efficiency.

In home and building systems, GAC is used in refrigerator cartridges, under‑sink filters, shower filters, and whole‑house tanks. Larger systems often send exhausted GAC to specialized facilities for reactivation, while small cartridges in homes are usually replaced rather than regenerated.

Side‑By‑Side: Efficiency Factors For Carbon Rods And GAC

Because both technologies share the same adsorbent, their efficiency is shaped less by the carbon chemistry and more by geometry, hydraulics, and how the system is used. Here are the main dimensions that matter in a real home.

Contaminant Removal Profile

Both carbon rods and GAC excel at what I call the “comfort layer” of water quality: removing chlorine, many taste and odor compounds, and a wide variety of organic molecules that make water smell stale or chemical. The Water Quality Association lists free chlorine, many VOCs, numerous synthetic organics, and certain disinfection by‑products as strong candidates for GAC treatment. Manufacturing descriptions of carbon rod filters emphasize the same classes of contaminants: organic matter, residual chlorine, odor, and some heavy metals.

Where GAC has a stronger research track record is in the heavy‑duty end of that spectrum: persistent industrial pollutants, pesticides, and disinfection by‑product precursors in challenging waters. A National Academies review of activated carbon in drinking water, as well as multiple EPA technical summaries, documents substantial reductions in pesticides, chlorinated solvents, and trihalomethane precursors in full‑scale GAC filters when contact times and bed depths are carefully designed. Wastewater treatment literature likewise shows granular activated carbon successfully removing pharmaceutical residues and other organic micropollutants that slip through conventional treatment.

Carbon rod systems use the same activated carbon, so their intrinsic ability to bind many of these organics is not fundamentally different. However, rods are commonly used in relatively small cartridges with limited bed length compared with a deep GAC tank. That limits contact time, especially at higher flow rates. Manufacturers counter this by designing the rod’s porosity and density to give water a defined flow path and avoid big internal channels, but the usable volume is still constrained by the cartridge dimensions.

When your main concern is everyday taste, odor, and chlorine, a well‑designed carbon rod or a GAC cartridge that has been tested to appropriate standards can both deliver excellent results. When your concern is a wide spectrum of industrial organics, especially at the whole‑home scale, the evidence base for deep GAC beds is richer, and that is why utilities and large commercial systems lean so heavily on GAC.

Flow Rate And Contact Time

Contact time is one of the most underrated efficiency levers in home filtration. Adsorption is not instantaneous; molecules must diffuse into carbon pores and find active sites.

Engineering data for GAC suggests contact times of around 10 to 30 minutes for reliable removal of many pesticides and disinfection by‑products in large filters. Home cartridges rarely achieve that, regardless of whether they use GAC or a carbon rod, but the principle is the same: slower flow and deeper media mean more contact and more complete adsorption.

Carbon rod designers use precise control of rod density and porosity to ensure that water does not simply tunnel through preferential pathways. Online density detection and strength testing, as described in carbon rod manufacturing reports, help ensure that every rod in a production run behaves consistently. In a well‑built cartridge, water is forced through the rod’s pore network, gaining more contact time per inch of length than it would if it could bypass loosely packed media.

GAC systems, by contrast, can vary widely. A carefully sized whole‑home GAC tank with the correct bed depth and flow rate can offer very generous contact time, closer to what is used in municipal plants. At the other extreme, a tiny GAC post‑filter crammed into a high‑flow faucet or refrigerator line can starve the media of contact time. This is one of the reasons I do not assume “GAC” automatically means “higher efficiency” in a home; the specifics of the design and flow rate matter more than the label.

In practical terms, carbon rods often shine in compact devices where engineering control over flow path is crucial, such as pitcher filters, small countertop units, or slim inline cartridges. GAC shines in larger housings where there is room to build a sufficiently deep bed.

Lifespan, Maintenance, And Performance Stability

No carbon filter, rod or granular, works forever. The adsorption sites fill up, and contaminants break through.

For GAC, engineering texts report useful lifetimes ranging from a few months for bulk total organic carbon removal in challenging surface waters, up to several years for taste and odor control in better‑quality water, depending on contact time and contaminant load. In municipal practice, utilities monitor surrogate parameters such as total organic carbon or specific target organics to determine when a GAC bed needs reactivation or replacement. Industry rules of thumb suggest that, for certain applications, about fifty cubic meters of water can be treated per kilogram of GAC before reactivation, though this varies widely with water quality.

Carbon rod manufacturers do not publish the same detailed engineering curves, but they do subject rods to adsorption tests that simulate real purification environments, measuring the rod’s ability to remove specific pollutants before it is approved for use. In household products, rod cartridges are usually replaced at fixed time or gallon intervals specified by the manufacturer.

The Water Quality Association warns that relying on taste, odor, or chlorine smell alone to judge carbon exhaustion is not safe, because health‑related organic contaminants can break through before you notice aesthetic changes. That warning applies to both rods and GAC. From a smart hydration perspective, the most efficient filter is the one you replace before breakthrough, not months afterward. So I strongly recommend following time‑ or volume‑based change‑out schedules and choosing systems that either monitor flow and time or make it easy to track.

On the mechanical side, carbon rods are engineered to resist breakage, with strength tests designed to keep the rods intact during service so they do not disintegrate or channel. GAC beds require different maintenance: backwashing to remove trapped solids and prevent biofilm and micro‑animal buildup in larger systems. In home GAC cartridges, backwashing is rarely available, so good pre‑filtration and timely replacement become even more important.

Microbial Behavior

Activated carbon of any format can become a home for bacteria. The National Academies review notes that microbial colonization of GAC beds is common: biofilms grow on the carbon surfaces, sometimes enhancing biodegradation of biodegradable organics but also raising concerns about bacterial breakthrough and the need for effective downstream disinfection.

The Water Quality Association echoes this, stating that GAC is not a primary disinfectant and that stagnant or spent carbon beds can support microbial growth. For that reason, GAC is often paired with chlorine, chloramine, or ultraviolet disinfection, and systems must be maintained so water does not sit stagnant in the carbon media for long periods.

Carbon rods are made of the same basic material, so they are subject to the same biological rules. If water sits for long periods, or if the system operates warm and undisturbed, biofilms can develop. Rod manufacturers focus on mechanical strength and adsorption performance; microbiological management depends on system design and user behavior.

For home hydration, this means that, whichever medium you choose, you should look for systems that either maintain disinfectant residual ahead of the carbon, add UV at the point of use, or are used frequently enough that water does not stagnate for days at a time. Regular cartridge replacement helps minimize biofilm buildup inside the filter.

Sustainability And Environmental Footprint

Sustainability is often overlooked when families choose water filters, but it is important for long‑term water wellness and environmental stewardship.

Several sources note that activated carbon is increasingly produced from renewable or waste feedstocks—coconut shells, agricultural residues, and even industrial by‑products—rather than exclusively from coal. This shift aligns with green chemistry and circular‑economy principles by valorizing waste streams and reducing landfill pressure.

For GAC specifically, manufacturers like Puragen and Calgon Carbon emphasize thermal reactivation. Large municipal and industrial systems send spent GAC to specialized kilns, where it is regenerated and reused, sometimes multiple times. Puragen reports that thermal reactivation can cut the carbon dioxide footprint of the media by over 90 percent compared with producing entirely new carbon, while also lowering life‑cycle cost.

Small household GAC cartridges are generally not reactivated; they are replaced and disposed of. Even then, the ability of GAC to be reclaimed at larger scales makes it part of a circular pathway, especially when paired with renewable feedstocks.

Carbon rod cartridges, being bonded blocks with binders and casings, are typically treated as single‑use devices in household and many commercial systems. Manufacturers are working on new binders that improve how effectively the activated carbon is used without sacrificing structural strength, and research into modified carbons for endocrine disruptors and antibiotics points to higher contaminant removal per unit of carbon in future designs. Automation and better process control in rod production also reduce waste, which improves sustainability on the manufacturing side, but the spent cartridges themselves usually go to waste streams rather than reactivation.

From a smart‑hydration sustainability standpoint, the most environmentally efficient option for a given household may be a combination: deep‑bed GAC tanks that can be reactivated for whole‑home treatment where flows are high, paired with compact cartridges—potentially carbon rods or small GAC blocks—for point‑of‑use polishing where water volume is modest but taste and convenience are paramount.

Summary Comparison: Carbon Rod vs GAC

To pull these threads together, it helps to lay out the key contrasts in a simple table. Remember that both options rely on the same core material; differences are mostly in format, scalability, and how easily engineers can tune the system.

Aspect |

Carbon Rod Filters |

Granular Activated Carbon Systems |

Physical format |

Solid rods made from activated carbon plus binders, extruded or compression molded with tightly controlled density and dimensions |

Loose activated carbon granules packed into beds or cartridges of varying depth and particle size |

Typical home uses |

Pitcher filters, compact countertop units, inline cartridges in small purifiers and some commercial devices |

Refrigerator filters, under‑sink and faucet cartridges, shower filters, whole‑house tanks, and municipal filters |

Main strengths |

Precise internal flow path, mechanical strength, compact footprint, strong focus on taste, chlorine, and organic removal; intensive quality control on density and adsorption performance |

Very broad track record for removing organics including many pesticides and industrial organics; flexible bed depth and contact time; can be thermally reactivated and reused at scale; widely used in certified POE and POU systems |

Main limitations |

Cartridge size naturally limits bed depth and contact time; spent rods are typically discarded rather than regenerated; multi‑media combinations are needed for hardness and many inorganic contaminants |

Requires careful design to avoid short contact times in small cartridges; standard GAC is not very effective for hardness, many dissolved salts, or many heavy metals unless specially modified; not a stand‑alone disinfectant |

Best fit in a smart home |

Compact, point‑of‑use polishing where taste, odor, and residual chlorine are primary concerns and space is tight |

Whole‑home treatment or high‑capacity drinking water systems where a wide range of organics and disinfection by‑products are concerns and where reactivation and deeper beds make sense |

How To Choose For Your Home Hydration System

When I work with families on hydration planning, I do not start by asking “rod or GAC?” I start by asking three other questions: what is in your water, how much water do you use, and how disciplined are you comfortable being with maintenance.

If your priority is simply getting rid of chlorine taste and “swimming pool” odors in municipally treated water at the kitchen sink, a well‑engineered carbon rod cartridge or a GAC cartridge tested to appropriate standards can both serve you well. In that scenario, I would pay more attention to certification, rated capacity, and clear replacement guidance than to the exact carbon format. Water Quality Association fact sheets emphasize using systems that are tested and certified to standards such as NSF/ANSI 42 for aesthetic improvements and 53 for health‑related contaminant reduction, and that advice applies to both rods and GAC.

If you are concerned about a broader suite of organic contaminants—industrial solvents, certain pesticides, or disinfection by‑products in older distribution systems—it often makes sense to rely on GAC as the backbone of your treatment strategy, especially for whole‑house coverage. The evidence base for deep GAC beds at removing these compounds, when contact times and bed depths are appropriate, is robust in the drinking water treatment literature and in EPA technology overviews. You can still use a carbon rod or small GAC cartridge as a “polisher” at the tap, but I would not put a small rod cartridge in front of a major contamination issue and expect it to carry the full load.

If your main issue is heavy metals such as lead, arsenic, or chromium, neither a plain carbon rod nor a plain GAC filter is the right primary solution. The Water Quality Association notes that standard GAC is not strongly effective for many heavy metals unless it is specially modified, and carbon rod descriptions, while mentioning removal of some heavy metals, do not claim broad or deep removal on their own. In these cases, I look for systems that pair carbon with ion‑exchange media, specialized adsorbents, or membrane processes and that are specifically certified for the metal of concern, with the carbon component focused on organics, chlorine, and taste.

For households that want whole‑home improvement—better water in every shower, reduced chlorine at every tap, and extra protection on organic contaminants—a full‑size GAC tank at the point of entry is often the most practical foundation. These systems can be sized to deliver substantial contact time, and exhausted carbon can be sent for reactivation. You can then add point‑of‑use filters, sometimes using carbon rods, where you fill bottles or cook, to fine‑tune taste and add additional barriers for specific contaminants.

Finally, be honest about your maintenance habits. Any carbon system that is not maintained becomes less efficient and can even become counterproductive as it accumulates contaminants and biofilm. If you are unlikely to remember complex schedules, choose systems with simple visual indicators, built‑in flow meters, or service contracts that keep you on track. Efficient filtration is not only about the media; it is about how reliably that media is refreshed before breakthrough.

FAQ

Are carbon rods or GAC safer from a health perspective?

Both carbon rods and GAC are based on activated carbon, which has been widely used in drinking water treatment and is even used in medical settings for certain poisonings. The National Academies and the World Health Organization recognize properly designed activated carbon treatment as a valuable barrier against many organic contaminants. Safety depends less on the media format and more on design, certification, and maintenance. A poorly maintained filter of either type can allow contaminants to break through or support microbial growth. Choosing a certified system and replacing cartridges on schedule is more important than whether the carbon is granular or rod‑shaped.

Does reactivatable GAC mean my home cartridge will be regenerated?

In practice, thermal reactivation is mainly used for large municipal and industrial GAC systems, where enough spent carbon is generated to justify specialized kilns. Home cartridges, whether filled with GAC granules or containing carbon rods, are generally replaced and disposed of. However, the ability to reactivate GAC at scale still matters environmentally, because it reduces the demand for entirely new carbon and cuts the carbon dioxide footprint of the industry. When you choose a whole‑home system that participates in that reactivation cycle, you are indirectly supporting a more circular model.

If my water already meets regulations, is upgrading to carbon rods or GAC worth it?

Regulatory compliance means your water meets safety standards at the treatment plant, but it does not guarantee that it will taste or smell the way you want, nor does it address every emerging contaminant of concern. Activated carbon, in either format, can further reduce disinfection by‑products, many residual organics, and the chlorine that affects taste and odor. From a hydration wellness perspective, people tend to drink more water when they actually enjoy the taste. So even in compliant systems, a well‑chosen carbon filter can be a meaningful upgrade in both comfort and health behavior, provided it is properly maintained.

As you evaluate carbon rods versus granular activated carbon for your hydration setup, remember that you are not choosing between “good” and “bad” technologies. You are choosing formats of the same powerful adsorbent, each with strengths that shine in different contexts. When you align the right medium with your water quality, flow needs, and maintenance habits—and pair it with solid science and third‑party certification—you turn filtration from a guess into a smart, sustainable part of your daily wellness routine.

References

- https://nepis.epa.gov/Exe/ZyPURL.cgi?Dockey=20007TH6.TXT

- https://en.wikipedia.org/wiki/Activated_carbon

- https://pmc.ncbi.nlm.nih.gov/articles/PMC11433758/

- https://wqa.org/wp-content/uploads/2022/09/2016_GAC.pdf

- https://www.jeeng.net/pdf-184089-106731?filename=106731.pdf

- https://www.researchgate.net/publication/229410273_Chapter_7_Activated_carbon_adsorption_in_drinking_water_treatment

- https://airpollutioncontrolequipment.com/general-carbon-activated-carbon/

- https://www.calgoncarbon.com/gac/

- https://generalcarbon.com/understanding-granular-activated-carbon-for-water-treatment/

- https://www.waterandwastewater.com/carbon-adsorption-in-wastewater-treatment/

Share:

Understanding the Importance of pH Range for RO Membrane Functionality

Understanding When and Why to Boost RO Pressure Toward 0.6 MPa (About 87 PSI)