Summary: To keep reverse osmosis (RO) membranes flowing during algal blooms, you need tougher pretreatment, smarter operating setpoints, and targeted cleaning that focuses on algae-driven organic fouling—not just mineral scale.

How Algal Blooms Overwhelm RO Membranes

When lakes, reservoirs, or coastal intakes experience harmful algal blooms (HABs), the water hitting your RO system changes overnight. Cyanobacteria and microalgae spike turbidity, silt density index (SDI), and dissolved organic carbon.

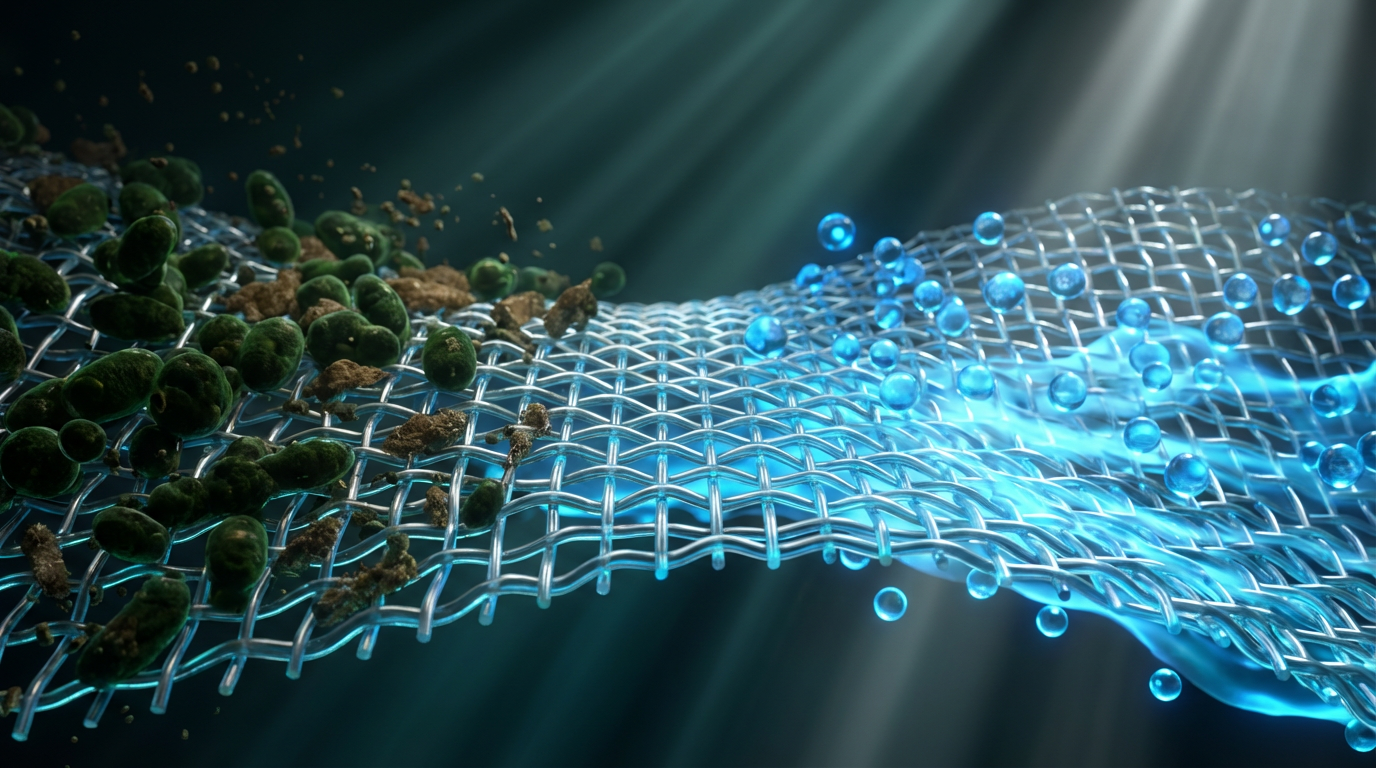

A review of seawater RO plants in Water Research shows that blooms can drive SDI beyond design limits, slash permeate flow by tens of percent, and force frequent clean‑in‑place (CIP) cycles or shutdowns. The problem is not just the cells themselves, but sticky algal organic matter (AOM)—polysaccharides and proteins that form a slimy cake layer and biofilm on membranes.

For systems treating lake‑influenced water, this means rapid clogging, rising differential pressure, higher energy use, and, if unmanaged, shortened membrane life and inconsistent drinking‑water quality.

Strengthen Pretreatment Before the RO Stage

Your first line of defense is to stop as much algae and AOM as possible before they ever touch the RO membrane. Kurita America and other membrane specialists emphasize robust pretreatment, especially in bloom season.

For utilities and larger systems, high‑performance options include:

- Dissolved air flotation (DAF) to float and skim buoyant algal cells.

- Coagulation–flocculation plus multimedia filtration to capture fine particles and some AOM.

- Micro‑ or ultrafiltration (MF/UF) as a membrane “shield” ahead of RO for highly variable bloom events.

These trains handle the sharp jump in coagulant demand and backwash frequency that classic sand filters alone struggle with during HABs.

For homes and small commercial systems using lake or surface water, focus on:

- A properly sized sediment filter to catch visible particles and much of the algal load.

- High‑capacity activated carbon to reduce natural organics that feed biofouling.

- Regular pre‑filter changes, especially mid‑ to late‑summer when blooms peak.

Long‑term, lake management strategies like aeration and nutrient control—highlighted by Vertex Aquatic Solutions—can cut bloom intensity, indirectly protecting every downstream RO membrane.

Tune RO Operation When Blooms Hit

Even with good pretreatment, you must adapt how you run the RO during a bloom. Field guidance from Axeon and Water Research case studies point to a few practical levers:

- Lower recovery temporarily. High recovery concentrates algae, AOM, and minerals at the membrane surface. Dialing recovery down by a few points reduces fouling pressure and buys stability.

- Watch SDI and differential pressure closely. A jump in SDI or a 15–20% rise in feed‑to‑concentrate pressure drop is an early warning to clean or adjust operations before damage becomes irreversible.

- Avoid over‑aggressive pre‑oxidation. Chlorine, ozone, or hydrogen peroxide can lyse algal cells, dumping more dissolved organics and toxins into the water and driving downstream fouling.

Note: Ohio Sea Grant testing found that municipal chlorine levels did not stop under‑sink RO units from removing microcystin, but oxidant dosing directly on raw bloom water still needs careful control to limit organic loading onto the membrane.

For homeowners, a simpler rule of thumb works: if faucet output drops noticeably, the RO unit runs constantly, or taste and TDS readings drift, treat that as a “bloom‑season checkup” trigger rather than waiting for a scheduled service date.

Clean and Restore Membranes Safely

When performance declines by about 10–15% from baseline—guidance echoed by industrial cleaning experts and Crystal Quest—it is time to clean, not just push the pump harder.

Key principles for bloom‑driven fouling:

- Target organics first. Use high‑pH alkaline cleaners designed for biofilm and organic matter; they break down the algal slime matrix and help lift AOM off the surface.

- Follow with low‑pH cleaning if needed. If scale (calcium, iron, or silica) is also present, an acidic step can dissolve it after organic layers are removed.

- Control temperature and pressure. Many cleaners work best around 80–95°F, while keeping pressure under about 60 psi to prevent mechanical stress and avoid forcing foulants deeper into the membrane.

- Clean by stage. As Kurita America notes, treating the most fouled downstream stages first prevents dislodged material from redepositing upstream.

For residential under‑sink RO, that typically means a simpler remove‑and‑soak protocol with manufacturer‑approved cleaners, followed by a thorough flush and discarding of initial product water.

With consistent pretreatment, adaptive operation, and thoughtful cleaning, your RO system can stay ahead of algal blooms—delivering safe, great‑tasting drinking water without sacrificing membrane life or peace of mind.

References

- https://pmc.ncbi.nlm.nih.gov/articles/PMC11509379/

- https://ohioseagrant.osu.edu/news/2017/u4e2f/odhe-study-watersystems

- https://dam.assets.ohio.gov/image/upload/epa.ohio.gov/Portals/28/documents/habs/TreatmentOptimizationProtocol.pdf

- https://www.canandaigualakeassoc.org/special-contribution-article-looking-to-purify-lake-water-from-cyanobacteria-and-pfos-consider-these-two-options/

- https://repository.oceanbestpractices.org/bitstream/handle/11329/755/Manual%20HAB%20and%20Desalination%20Chap%207-WC.pdf?sequence=1&isAllowed=y

Share:

The Importance of Heat Dissipation in Extreme Temperatures for RO Systems

Adjusting Your RO System for Daily Water Quality Variations