As a smart hydration specialist, one of the most frequent questions I hear from homeowners and small businesses is deceptively simple: “How long will my RO membrane really last?” Some people are told one to two years, others hear five or even six. The truth is more nuanced, and understanding that nuance is the difference between a reliable, healthy drinking water setup and a system that quietly drifts out of spec.

In this article, I will walk you through what the science and field experience actually show about reverse osmosis (RO) membrane lifespan, why it varies so much, and what you can do, practically, to keep your membrane performing well for as long as possible without compromising water quality or your health.

What An RO Membrane Really Does

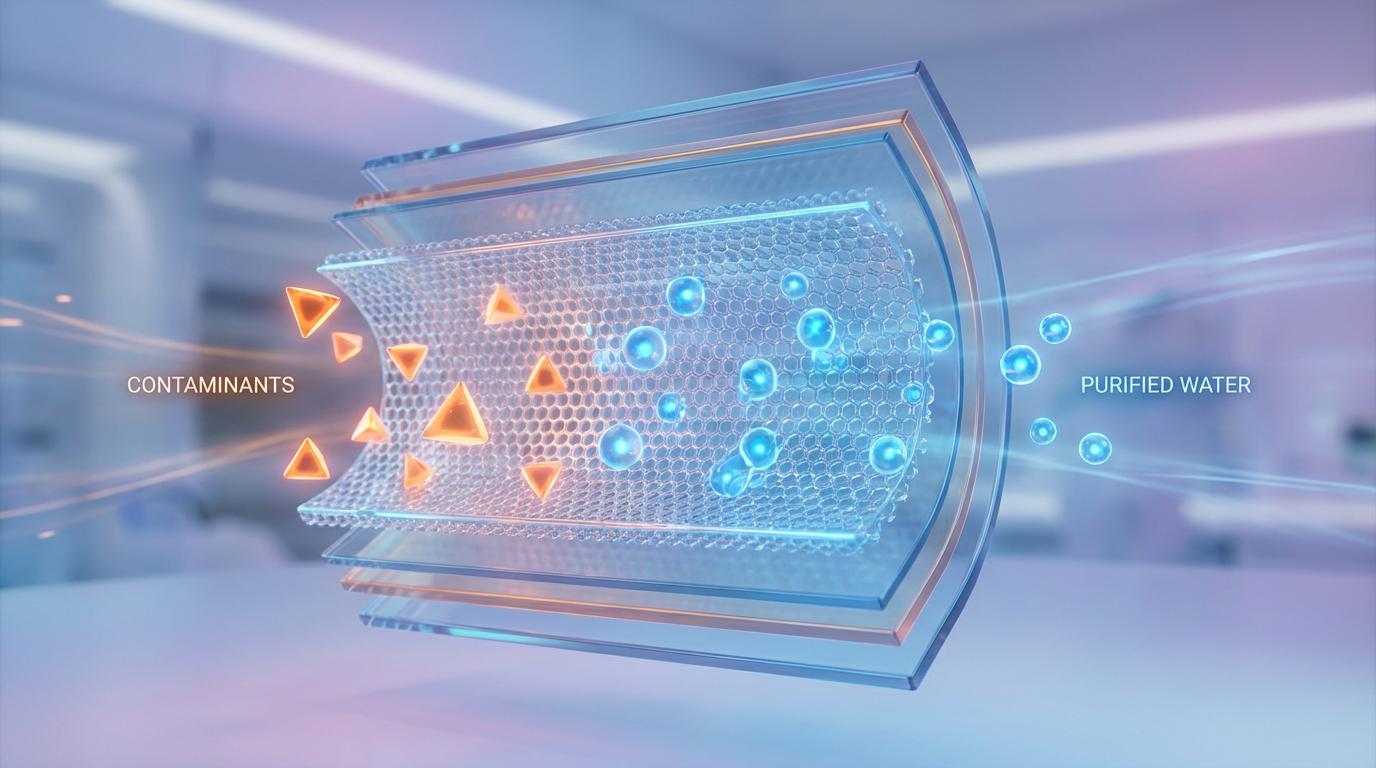

A reverse osmosis membrane is the heart of an RO system. It is a semi‑permeable barrier that, under pressure, allows water molecules to pass while rejecting dissolved salts, metals, many microorganisms, and a wide range of other contaminants. Guidance from the University of Nebraska–Lincoln Extension and manufacturers such as Axeon and SoftPro describes modern RO membranes as thin‑film composite (TFC) or cellulose‑based materials.

TFC membranes use a very thin polyamide layer bonded to a porous support. They are valued for high rejection of total dissolved solids (TDS) and excellent durability when operated correctly. However, they are vulnerable to chlorine, which can chemically attack the polyamide. That is why you see carbon pre‑filters in so many RO systems: they remove chlorine before it reaches the TFC membrane.

Cellulose membranes, such as cellulose acetate or cellulose triacetate, are more tolerant of chlorine but generally offer lower rejection and can be more prone to microbial growth, especially when water sits stagnant. Some manufacturers also offer cellulose acetate blends that try to balance flow, chlorine resistance, and performance.

Regardless of the exact material, the membrane is not a permanent component. It gradually clogs, scales, or degrades. Understanding the typical ranges for membrane life is the first step toward managing expectations and budgets.

Typical Lifespan: Ranges, Not a Single Number

Across independent guidance from residential and industrial water treatment providers, a clear pattern emerges. In most home and light commercial drinking water systems, the RO membrane typically lasts somewhere between about two and five years when the system is reasonably well maintained.

Residential focused sources such as Watermart, Affordable Water, and Membrane Solutions converge on this two‑to‑five‑year window, with two to three years being common in average homes and closer to four or five years when the source water is relatively soft and clean and maintenance is consistent. Industrial and well‑engineered systems can sometimes push longer. DuPont reports that properly treated membranes in industrial setups can often deliver around six years of service before replacement, and industrial experts such as Nathan Olszak of Complete Water Solutions design systems specifically to protect membranes through careful pretreatment and monitoring.

It is just as important to separate the membrane’s life from the rest of the system. The manifold, housings, faucet, and plumbing commonly last on the order of ten to fifteen years when cared for, according to general lifespan guidance summarized by EAI Water. Pressurized storage tanks often last around five to ten years before the internal bladder loses performance. The consumable filters are much shorter lived.

The table below summarizes typical component lifespans under normal conditions, drawn from multiple residential sources.

Component |

Typical lifespan (under normal use) |

Notes on variability |

Sediment pre‑filter |

About 6–12 months |

Closer to 3–6 months in very sediment‑heavy water |

Carbon pre‑filter |

About 6–12 months |

Shorter if chlorine or organics are high |

Carbon polishing (post) filter |

About 12 months |

Affects taste and odor |

Remineralization post‑filter |

About 12 months |

Adds calcium and magnesium back for taste and balance |

RO membrane (residential) |

About 2–5 years |

Often 2–3 years; up to ~5 years with good water and maintenance |

RO membrane (well‑maintained industrial) |

Around 3–6 years |

Dependent on pretreatment and controlled operating conditions |

Pressurized storage tank |

About 5–10 years |

Air bladder fatigue is the usual failure mechanism |

RO system hardware (manifold, faucet, plumbing) |

About 10–15 years |

Time to consider full upgrade to newer, more efficient technology |

These are not promises; they are realistic planning numbers grounded in field data. To understand why a particular membrane ends up at the low or high end of the range, you have to look at how membranes actually age.

Why RO Membranes Age: Fouling, Scaling, And Stress

From a science and engineering perspective, two degradation mechanisms dominate RO membrane life: fouling and scaling. A review of membrane life‑cycle issues in the journal Desalination, along with technical notes from Axeon, JMark Systems, and others, describes these in detail.

Fouling occurs when particles, organic matter, and microorganisms accumulate on the membrane surface or in its pores. This includes silt and rust, natural organic material, oils, and biofilms from bacteria. Fouling reduces water flux, increases pressure requirements, and can cause irreversible changes if allowed to intensify.

Scaling is the deposition of minerals such as calcium carbonate, other hardness minerals, iron, manganese compounds, and silica. Hard water is a primary driver. SoftPro cites research showing that hard‑water conditions can cut membrane lifespan by about thirty percent compared with soft water because of the additional scaling stress.

On top of fouling and scaling, chemical and mechanical stresses also matter. Chlorine damages many TFC membranes if pre‑filters do not remove it effectively. Operating at excessive pressure can deform the membrane structure. Running very cold water lowers productivity and encourages operators to increase pressure to compensate, further stressing the membrane. The University of Nebraska–Lincoln Extension reports that treated water output can drop by roughly one to two percent for every degree Fahrenheit the feed water falls below about 77°F; at around 45°F well water, you may only see about half the output you would get at 77°F.

Once you see membrane performance begin to drop, it typically does not decline linearly forever. JMark Systems notes that membrane performance tends to degrade gradually at first and then more rapidly once fouling or scaling reaches a tipping point. That is why early detection of performance changes is so valuable.

What Actually Changes Membrane Lifespan

Several practical variables explain why one homeowner sees a membrane fail after a year and another comfortably reaches four years or more.

Feedwater Quality: Hardness, TDS, Iron, Chlorine, And Microbes

Water quality is the single most important factor. Feedwater that is high in hardness minerals, TDS, iron, manganese, or problem gases causes more aggressive scaling and fouling. SoftPro highlights that high iron and manganese stain and foul membranes and that hydrogen sulfide gas, responsible for “rotten egg” odors, can damage membrane materials.

Chlorine is a special case. University of Nebraska–Lincoln and manufacturers such as Dultmeier and Membrane Solutions all emphasize that TFC membranes are vulnerable to chlorine. If carbon pre‑filters are exhausted or undersized, chlorine can reach the membrane and cause rapid chemical degradation, driving premature failure despite otherwise good water.

Microbial quality matters too. Extension publications note that bacteria can damage the membrane and colonize surfaces. When pre‑filters or carbon stages are installed ahead of a membrane on non‑chlorinated water, they can become sites for bacterial growth unless the overall system is disinfected periodically.

In practical terms, if your home has very hard water, high TDS, visible staining, or persistent odors, you should expect RO membranes to sit at the shorter end of the lifespan ranges unless you add targeted pretreatment such as softening, iron removal, or additional filtration upstream.

Pretreatment And System Design

Effective pretreatment acts like bodyguards for your RO membrane. Sediment filters capture dirt, rust, and silt before they reach the membrane. Carbon filters remove chlorine, many organics, and off‑tastes while protecting chlorine‑sensitive TFC elements. In systems that handle heavy sediment loads, Watermart and others recommend installing additional pre‑filters before the RO unit so that the built‑in sediment stage does not carry the entire burden.

Industrial suppliers such as Axeon and DuPont also stress pretreatment as non‑negotiable. They specify upstream filtration, softening where needed, antiscalant dosing, and pH adjustment to set the membrane up for success. Good system hydraulics, with balanced flow and minimal dead zones, help prevent local fouling hot spots along the membrane surface.

Inadequate pretreatment has a visible signature: frequent clogging of pre‑filters, rapid rise in pressure differential across the membrane, and declining permeate quality long before the theoretical membrane lifespan is reached.

Operating Conditions: Pressure, Temperature, And Recovery

RO is a pressure‑driven process, and the membrane’s life depends on staying within the operating envelope the manufacturer specifies. Consumer‑oriented guidance from Waterdrop and various residential providers places typical household RO operating pressure in the range of roughly 40 to 80 psi. Too low, and you get poor rejection and slow production. Too high, and you mechanically stress the membrane and housings.

Temperature plays a similar role. Warmer feed water (within safe limits) improves water flux and helps resist fouling, while excessively hot water damages the membrane. Crystal Quest, describing membrane cleaning procedures, recommends cleaning solution temperatures at or below about 86°F and flushing with water at or above roughly 68°F for some processes, underscoring that there are safe bands, not arbitrary extremes.

Recovery—the fraction of feed water converted to treated water—also affects membrane stress. The University of Nebraska–Lincoln Extension notes that many residential systems operate at about 20 to 30 percent recovery; pushing recovery too high to “save water” without appropriate pretreatment and design can concentrate scaling salts at the membrane surface and shorten life.

Usage Patterns And Stagnation

It is tempting to assume that light use always extends membrane life, but that is not always true. EAI Water points out that very low usage can lead to stagnant water, membrane fouling, and biofilm growth if the system is not flushed regularly. On the other end of the spectrum, very high daily consumption loads the membrane faster and may require more frequent replacement, especially if pretreatment is marginal.

You can see this contrast in practice. A busy car wash with RO‑based spot‑free rinsing may go through membranes more quickly because of huge daily volumes. That is why Dultmeier recommends weekly TDS checks and careful softening and chlorine control. At the other extreme, a vacation home with an under‑sink RO that sits idle for weeks at a time can develop taste and odor issues and microbial growth if the system is never sanitized or flushed.

Maintenance Discipline: Cleaning, Sanitizing, And Monitoring

Nearly every reputable source, from Affordable Water to DuPont, converges on one message: proactive, guideline‑based maintenance is the most reliable way to avoid unplanned downtime and early membrane replacement.

Pre‑ and post‑filters should be replaced every six to twelve months in most homes, according to Atlantic Blue Water Services, Watermart, and Affordable Water. Stretching those intervals might not immediately change taste, but it allows more sediment and chlorine to reach the membrane, shortening its life. Annual sanitization of the system and storage tank, as recommended by Affordable Water and Crystal Quest, helps control bacterial growth and biofilm that can foul the membrane and tubing.

Monitoring is the other half of the equation. JMark Systems, Dultmeier, and Axeon highlight the value of watching normalized permeate flow, pressure differential, and salt passage over time. In practice, this can be as simple as logging TDS readings at the RO faucet and occasionally checking pressure if your system has gauges.

When you see a ten to fifteen percent drop in normalized flow, a similar increase in pressure drop, or a clear rise in TDS, it is time to investigate cleaning and, eventually, replacement.

Cleaning Versus Replacement: How To Decide

Homeowners often ask if they can “save” an aging membrane with a good cleaning instead of replacing it. The answer depends on age, fouling severity, and how critical your water quality needs are.

Crystal Quest recommends cleaning residential membranes when faucet output drops, TDS in filtered water rises, or taste or odor changes, and suggests cleaning at least every six to twelve months as a preventive measure. For light fouling or small systems, they describe removing the membrane, soaking it for thirty to sixty minutes in the proper cleaning solution, rinsing with chlorine‑free water, reinstalling, and flushing the system for at least ten minutes before drinking. High‑pH cleaners target organic fouling and biofilm, while low‑pH cleaners dissolve mineral scale such as calcium carbonate and metal oxides.

For larger or more severely fouled systems, clean‑in‑place (CIP) methods are recommended. JMark Systems and DuPont describe CIP cycles where cleaning solution is circulated through the membrane at low pressure (often below about 60 psi) for thirty to sixty minutes per stage, followed by soaking and thorough rinsing. Cleaning chemistry is matched to the fouling type; for example, acidic solutions for scale and alkaline solutions with chelants for organics and biofilm.

But there are limits. Crystal Quest notes that membranes more than about three to four years old, or those that are heavily fouled, may not respond well to cleaning and that replacement is usually more cost‑effective. JMark Systems points out that replacement is indicated when cleaning no longer restores performance, when chemical attack or abrasion has caused irreversible damage, or when operators are forced to push the system beyond safe pressure limits just to maintain output.

From a home hydration perspective, you should absolutely prioritize replacement over heroic cleaning once a membrane has been in service near the upper end of its expected lifespan and your TDS, taste, or flow indicators show clear decline.

It is not worth gambling with drinking water quality to squeeze a few extra months out of an exhausted membrane.

Practical Ways To Extend Membrane Life At Home

Even though RO membranes are consumables, you have a lot of control over where in the two‑to‑five‑year window your membrane will land.

Protect The Membrane With Solid Pretreatment

Follow your manufacturer’s schedule for sediment and carbon filter changes, typically every six to twelve months. Sediment filters capture the dirt and grit that would otherwise clog the membrane. Carbon filters protect TFC membranes from chlorine and remove many organic compounds that contribute to fouling.

For homes with very sediment‑heavy water, Watermart suggests installing an additional pre‑filter upstream of the RO unit. In practice, this often means a dedicated whole‑house sediment filter or an extra cartridge under the sink. This inexpensive step can dramatically reduce how much dirt reaches the RO membrane.

If your water is hard, a properly sized water softener upstream of the RO system can be a game‑changer. Case studies summarized by SoftPro show that adding softening in hard‑water areas extended membrane life from about eighteen months to around four years in one Southern California home, primarily by reducing scaling stress.

Respect The Calendar, Not Just Your Taste Buds

Many RO owners wait to replace filters or membranes until the water tastes “off.” That is a late indicator. By that point, some damage to the membrane may already be done. Atlantic Blue Water Services encourages users to lean on calendar reminders and schedules instead of waiting for noticeable problems, because different components have very different lifespans, from six months to several years.

A simple approach is to log installation dates on the filter housings with a permanent marker and set reminders on your cell phone calendar for six, twelve, and twenty‑four months. When in doubt, follow the shorter interval if your source water is challenging.

Watch Your Numbers: TDS And Pressure

Total dissolved solids meters are inexpensive and powerful tools. Dultmeier recommends weekly TDS checks in high‑demand commercial applications; for home drinking water, monthly checks are often sufficient. You immerse the meter in a glass of RO water, swirl briefly, and read the ppm value.

Watermart notes that properly functioning home RO water often reads below about 50 ppm. Dultmeier uses a rough threshold of about 40 ppm in car wash applications as the point where spotting becomes visible. For household hydration, you are less concerned with vehicle spots and more with trends. If your RO water has historically been in the 10–30 ppm range and you see readings steadily creeping up despite recent pre‑filter changes, it is a strong sign that your membrane is aging or fouling.

Pressure and flow trends tell a complementary story. JMark Systems cites a ten to fifteen percent drop in normalized permeate flow or a similar rise in differential pressure as a typical threshold for initiating a cleaning. In a home system without gauges, you may notice this as noticeably slower flow from the RO faucet or a storage tank that seems to take much longer to refill.

Operate Within Safe Pressure And Temperature

Stay within the pressure range specified for your unit, often around 40 to 80 psi for household systems. If your incoming pressure is low, consider a booster pump rather than “just living with” poor performance that tempts you to ignore maintenance. At the other extreme, do not feed the system with unusually hot water in an attempt to increase output; that can damage the membrane. The guidance from Crystal Quest and industrial CIP protocols around staying at or below about 86°F during cleaning is a good reminder that RO membranes are not designed for hot water.

Keep The System Clean And Fresh

Annual sanitization helps keep biofilm at bay. Affordable Water recommends disconnecting the system, disinfecting the storage tank and tubing, and flushing thoroughly. Crystal Quest reinforces that you should always discard the initial permeate after cleaning to flush out cleaning chemicals.

Atlantic Blue Water Services adds a simple but often overlooked practice: fully draining the storage tank about every two weeks. This ensures that the water you drink is fresh, helps maintain proper pressure for the membrane, and reduces stagnation. They also point out that the water you drain is still clean and can be reused for non‑drinking purposes such as watering plants.

For long‑term shutdowns or backup systems, Crystal Quest recommends using a dedicated membrane preservative solution to prevent bacterial growth and drying. This is especially relevant if you have a seasonal property or a system used only part of the year.

Plan For Smart Upgrades

As RO technology evolves, newer membranes and system designs can reduce fouling and extend life. Axeon notes that upgrading to newer RO, nanofiltration, or ultrafiltration membranes with higher fouling resistance and better hydraulics can be a cost‑effective way to improve performance without replacing the entire system. DuPont also describes “smart” RO systems with advanced monitoring and controls that automatically adjust to varying conditions and support remote diagnostics.

If your RO system is approaching ten years of age, EAI Water suggests reassessing whether a full replacement or an upgrade to more efficient, better‑monitored technology is appropriate. At that stage, you are not just buying a new membrane; you are investing in safety, convenience, and long‑term operating cost.

Health, Taste, And The RO Versus Ceramic Question

RO membranes are extremely effective, but they are not the only option for drinking water. Doulton, a ceramic filter manufacturer, highlights several trade‑offs that are important for health‑conscious households to understand.

RO systems remove a broad spectrum of contaminants, but they are not selective. They strip out many beneficial minerals such as calcium and magnesium alongside undesirable substances. Over the very long term, some research has raised concerns about exclusive consumption of highly demineralized water and potential links to mineral deficiencies. At the same time, many RO systems now include remineralization stages that add calcium and magnesium back into the treated water to improve taste and support a more balanced mineral profile. Watermart and Waterdrop both describe such remineralization filters as standard or optional stages that are replaced about once per year.

RO systems also tend to require more maintenance and may produce wastewater. Doulton points out that for every gallon of purified water, several gallons can be sent to drain in many conventional systems, which increases water use and may raise utility bills in metered homes. The University of Nebraska–Lincoln Extension notes that typical household RO units are often designed for recoveries around twenty to thirty percent, meaning 70–80 percent of feed water goes to drain. Newer designs, such as high‑efficiency tankless units described by Waterdrop, can improve the pure‑to‑drain ratio, but the principle remains: RO is more water intensive than some alternatives.

Ceramic filters, in contrast, preserve beneficial minerals, generate no wastewater during normal use, and can often be cleaned to restore flow for extended lifespans. They may be an excellent choice for homes on relatively clean municipal supplies where the primary goals are taste improvement and basic contaminant reduction, not the comprehensive ionic removal that RO offers.

From a hydration and wellness standpoint, the key is to match the technology to your water quality and health needs. If your water contains health‑related contaminants such as nitrate, arsenic, or very high TDS levels, RO is often the right tool, ideally combined with remineralization. If your main concerns are chlorine, taste, and some metals, a high‑quality ceramic or carbon‑based system may be sufficient and less maintenance intensive.

Environmental Perspective: What Happens To Old Membranes?

There is a wider sustainability story behind membrane life. A review in Desalination points out that end‑of‑life RO modules are already generating thousands of tons of solid waste per year globally as membranes are discarded in landfills. Because they are largely non‑biodegradable, they persist for many years, and some may leach residual chemicals.

The same review emphasizes that the first step in minimizing this waste is extending membrane life through better materials, system design, and operation. That is exactly what you do when you follow pretreatment, maintenance, and monitoring best practices: you reduce the number of membranes that need to be manufactured and eventually disposed of.

There is also growing interest in recycling and repurposing spent membranes. Research summarized in that Desalination review shows that discarded RO elements can sometimes be converted into microfiltration or ultrafiltration elements for lower‑pressure, lower‑selectivity applications after appropriate modification. This gives them a “second life” instead of sending them directly to a landfill.

SoftPro adds a practical angle for homeowners, noting that some manufacturers offer membrane take‑back or recycling programs and that specialized waste management companies may accept membranes for recycling. If you are replacing a significant number of membranes in a commercial or multi‑unit context, it is worth asking your supplier or installer about these options.

From a smart hydration perspective, maintaining your system well so membranes last toward the higher end of their service range, choosing high‑quality membranes that perform reliably, and exploring recycling options where available are all part of a more sustainable water strategy.

Short FAQ On RO Membrane Longevity

How often should I replace my RO membrane?

Most residential systems need a new membrane about every two to five years. In practice, two to three years is common, but if your water is soft, TDS is modest, and you maintain filters and sanitize the system regularly, four to five years is realistic. Let performance guide you: rising TDS at the RO faucet, declining flow even after pre‑filter changes, or noticeable changes in taste and odor are clear signs that replacement is due.

Does using the system less often extend membrane life?

Not always. Very light use can allow water to stagnate, encouraging microbial growth and fouling. EAI Water notes that low usage without regular flushing can shorten membrane life in its own way. The healthiest pattern for most systems is moderate, regular use with periodic tank draining and annual sanitization so water never sits for long periods.

Can I clean my membrane instead of replacing it?

In some cases, yes. Crystal Quest and industrial experts like JMark Systems describe cleaning protocols that can restore performance when fouling or scaling is not too advanced and the membrane is not very old. However, membranes that are heavily fouled or older than about three to four years often do not justify aggressive cleaning; replacement is usually more cost‑effective and safer for drinking water quality.

When you understand why RO membranes age, what drives their lifespan variability, and how to monitor them intelligently, you move from guesswork to informed stewardship of your home hydration system. Thoughtful pretreatment, disciplined filter changes, periodic sanitization, and simple tools like a TDS meter can easily add years of reliable service to each membrane. The payoff is not just fewer replacements; it is the quiet confidence that the water you and your family drink every day is as clean, consistent, and well‑managed as the rest of your wellness routine.

References

- https://pubmed.ncbi.nlm.nih.gov/28097920/

- https://extensionpublications.unl.edu/assets/html/g1490/build/g1490.htm

- https://www.affordablewaterinc.com/reverse-osmosis-maintenance-tips-for-first-time-owners

- https://www.dultmeier.com/how-often-should-you-change-your-ro-membranes-a-complete-guide

- https://www.membrane-solutions.com/blog-How-Often-Should-RO-Membrane-Be-Replaced

- https://complete-water.com/blog/extend-the-life-span-of-your-industrial-ro

- https://www.dupont.com/knowledge/importance-of-industrial-ro-system-maintenance.html

- https://eaiwater.com/how-long-does-a-reverse-osmosis-system-last/

- https://pt.ionexchangeglobal.com/maintaining-your-reverse-osmosis-membrane/

- https://www.jmarksystems.com/blog/anvzg1ligd4o9wy7uuxers4ikh4szp

Share:

Why Cold-Water RO Systems Are More Efficient Than Hot-Water Setups

Understanding How Much Chlorine Your RO System Can Really Handle