When a water storage tank starts to gurgle, most people either ignore it or assume it is just “one of those plumbing sounds.” As someone who spends a lot of time diagnosing well systems, pressure tanks, and cold-water storage for home hydration setups, I can tell you that gurgling is usually your system trying to talk to you. The good news is that if you listen early, you can often prevent expensive failures and protect both your water quality and your peace of mind.

In this guide, I will walk you through what those gurgling sounds really mean, how to tell tank-related noises from drain or septic problems, and what practical steps you can take before calling in a professional. The explanations are grounded in field practice and in guidance from technical sources such as InspectApedia, Tankreline, Firstank, land-grant university extensions, and long-time plumbing contractors.

What “Gurgling” Really Is in a Water Storage System

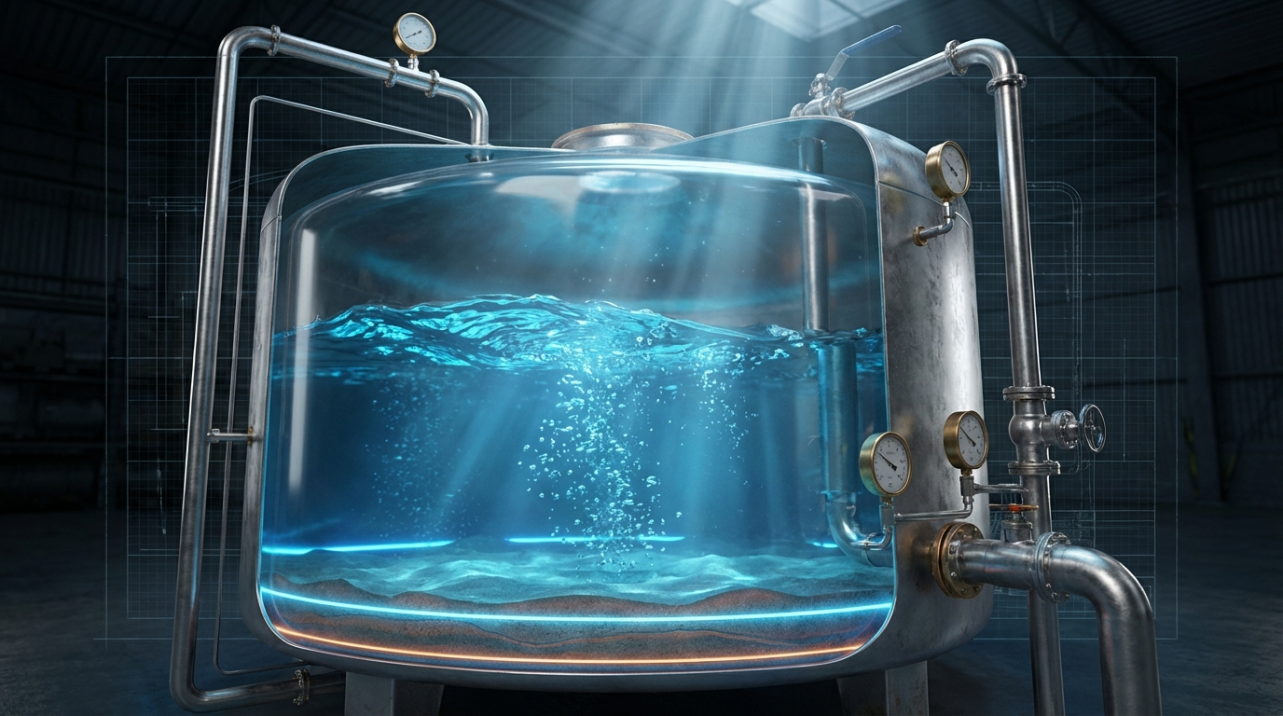

Gurgling is the sound of water and air struggling to share the same space. In a water storage or pressure tank system, that usually means air pockets, turbulence around restrictions, or water moving past sediment deposits.

Technical references on water pressure and storage tanks describe bubbling or gurgling noises at the tank as a common sign of air in the water system rather than a purely mechanical rattle. You may also hear gurgling as water flows through nearby pipes, particularly if those pipes are partially filled with air instead of being completely full of water.

The context matters as much as the sound itself. A few common patterns show up again and again in real homes:

If the gurgling happens mainly while the well pump is running, it often points to air being drawn in somewhere between the well and the tank, or to the well water level being temporarily too low.

If the tank continues to gurgle for nearly a minute after the pump shuts off, experienced well diagnosticians see that as a red flag for a leaking check valve or foot valve that is letting water drain backward and repeatedly re-triggering the pump.

If the gurgling coincides with the sound of water sloshing or popping inside an older cold-water storage tank, sediment and mineral buildup are likely involved.

Getting a handle on which pattern you are hearing is the first step toward a safe fix.

The Science Behind Gurgling: Air, Sediment, and Pressure

Gurgling in a water storage tank is rarely random. It almost always traces back to one of three core ingredients: unwanted air, internal obstructions like sediment, or pressure events that stir things up.

Air Being Pulled into the System

InspectApedia’s detailed troubleshooting of gurgling water tanks notes that air in the system is one of the most common underlying causes. In a well-and-pressure-tank setup, there are two especially important air paths.

One path is through the well itself when the pump is pulling water out faster than the aquifer can recover. As the water level drops near the pump intake, the pump begins to draw in some air along with water. That air then gets pushed into the pressure or storage tank, where it creates bubbling and gurgling as it mixes and separates while the pump runs.

In this scenario, the gurgling typically appears only while the pump is running and tends to be worse during long draw periods such as irrigation, long showers, or back-to-back laundry loads. A shallow well with limited static head, such as the 38‑ft wells discussed in some case histories, is particularly vulnerable because there is less water “cushion” above the pump.

The other path is through leaks on the suction side of the system. If there is a small leak in the piping between the well and the tank, especially at a joint that sits above the water level, that fitting can dribble water out under pressure and then suck air in when the pump stops. Over time, the tank fills with small bubbles and the plumbing starts to spit air and gurgle at faucets as well.

In both cases, the sound you hear is water trying to move around and expel that air. The longer the issue goes on, the more stress you put on the pump and the more erratic your water delivery becomes.

A simple example from the field makes this concrete. In one low-yield well with a 500‑gallon holding tank, the homeowners reported a “boiling” gurgle at the tank only when they irrigated the yard. Inspection showed that the well could not keep up with the irrigation demand. Each time the pump cycled on, it pulled the water column down and sucked in air. When irrigation was throttled back and the pump was protected against running the well too low, the gurgling vanished.

Trapped Air in Pipework and Cold-Water Tanks

A separate, but related, issue is trapped air in the distribution pipes and cold-water storage tanks above or beside the main supply. Tankreline’s guidance on noisy cold-water tanks points out that air pockets in pipework are a classic cause of gurgling or bubbling noises when water runs.

This is especially common in gravity-fed systems or in homes where a loft or attic tank supplies fixtures. After maintenance, a power outage, or a period of low use, air can become trapped at high points in the plumbing. When you reopen a faucet, the water pushes through that air pocket. The air compresses, releases, and moves along in bursts, producing a gurgling or chattering sound in the tank and the lines.

Tankreline recommends a straightforward method to bleed those pockets: open the tap that is furthest and highest from the cold-water tank and let it run until the gurgling subsides. In practice, I often pair that with a visual check of any accessible tank vent or overflow to make sure it is not blocked, because restricted venting can make it harder for trapped air to escape.

Aquarium and reef tank owners run into a very similar phenomenon in their drilled overflow systems. When water completely covers a drain opening and turns it into a full siphon, air is excluded. As soon as some air gets mixed back in, pockets form and “burp” up the line, creating loud gurgling. Experienced hobbyists solve it by deliberately balancing air and water at the overflow and by adjusting the outlet position so air can vent smoothly. The physics in a home storage tank are not identical, but the core idea is the same: when air has no easy path out, you hear it fight its way through the system.

Sediment and Mineral Buildup Stirring the Water

Sediment and mineral scale are the quiet culprits behind a lot of noisy tanks. In regions with hard water, calcium and magnesium settle out and collect in the bottom of any large tank over time. Tankreline notes that sediment and mineral buildup at the base of a cold-water tank can lead to popping or crackling as the water heats and cools around those deposits.

Water-heater specialists such as All Pro Plumbing, Smith’s Plumbing, Tennessee Standard Plumbing, and educator-plumber Roger Wakefield describe the same effect in hot water tanks. They consistently link popping and rumbling noises to a dense layer of mineral scale that traps water. As the heater fires, trapped water flashes to steam and collapses, producing both noise and extra stress on the tank. Because the heat has to fight through sediment, energy use rises and overall efficiency drops.

While a cold potable storage tank may not have a burner underneath it, the turbulence created by water entering or leaving a tank full of sediment can produce its own distinctive gurgling. Narrowed passages at the inlet fitting, such as the partially clogged iron inlet tees described on InspectApedia, force water through tight spaces and promote bubbles and turbulence. The more sediment and rust that accumulate, the louder and more chaotic the sounds become.

A practical illustration comes from installations where the water softener or filters are installed only after the pressure tank.

In those setups, the tank still receives untreated, iron-rich water. Over a few years, the iron and sediment deposit right at the tank inlet. Owners often report a growing chorus of hisses, pops, and gurgles during fills. When the fitting is cleaned or replaced and the tank is flushed, both the noise and the pressure fluctuations drop noticeably.

Pressure Surges, Water Hammer, and Bladder Problems

Not all noisy events are pure gurgling. Sometimes you hear a mix of banging, thumping, and gurgling, especially around pressure tanks that are short-cycling or poorly supported.

Firstank’s overview of water storage tank noises describes banging or hammering as hydrostatic shock when trapped air and rapidly closing valves send pressure waves through the plumbing. MyBuilder’s discussion of noisy pipes during tank fills points to water hammer and loose pipes as a common issue, recommending water hammer arrestors and better pipe support.

Inside the tank, the air or bladder cushion is supposed to absorb these surges. When that cushion is compromised, the tank can waterlog and the pump begins to start and stop in quick succession. Firstank notes that this rapid cycling often goes hand in hand with unusual clicks and clunks around the pressure switch and check valves.

A case shared in a well-water forum illustrates how this relates to gurgling. A homeowner with a noisy pressure tank drained it completely, then checked the bladder precharge with a tire gauge and found only 25 psi where about 38 psi would be typical for a system cutting in at 40 psi. After adding air with a small compressor up to 38 psi, restoring power, and refilling the system, the pressure climbed to a normal cut-out around 55 psi and the noise disappeared. The low precharge had allowed too much water into the tank, reducing the air cushion and contributing to hydraulic noise and water hammer.

Bladder failures can be even more dramatic. InspectApedia points out that a ruptured internal bladder can generate new gurgling, squeaking, or screeching, followed by obvious symptoms like water at the tank’s air valve and very frequent pump cycling. In that situation, the gurgling is a symptom of a tank that can no longer separate air and water properly, and replacement is usually the only long-term solution.

Is the Gurgling Really from the Tank? How to Tell Tank Noises from Drain and Septic Issues

In a whole-home hydration system, it is easy to blame every strange sound on the storage tank. In reality, some of the most serious gurgles actually come from the drain or septic side, especially when storms or blockages are involved.

University of Florida’s IFAS Extension describes how heavy rainfall and hurricanes can saturate the soil around a septic drainfield. When the ground is already soaked, it cannot accept more wastewater, so effluent backs up in the pipes. A classic warning sign in that situation is gurgling in toilets and drains, sometimes along with slow sinks and sewage odors around the house or yard.

Penn State Extension and septic-focused resources such as Hotrod Septic echo the same concern. Persistent gurgling from toilets and drains, combined with sluggish fixtures or damp, spongy ground over the drainfield, is treated as a strong warning that the septic system is not accepting flow properly and needs inspection and pumping. The gurgling noise in this context is not coming from your potable water storage tank at all; it is a sign of wastewater fighting for a path out.

Plumbing pros who specialize in gurgling drains, such as those featured by Precision Today, add another layer. They note that when multiple drains gurgle at once, especially with sewer-like odors, the problem often lies in a partially blocked main sewer line or a vent stack obstruction. Roof vents blocked by debris, nests, or even mud-dauber wasps, as RV technicians have observed, can prevent air from entering the piping, creating negative pressure and gurgling when fixtures drain.

For your water wellness, the distinction matters. Tank-related gurgling is usually about air, sediment, or pressure in your clean water system. Drain and septic gurgling can signal contamination risks, including possible exposure to sewage. When in doubt, pay attention to where the sound originates and what other symptoms accompany it. Gurgling at the tank during pump runs points one way; gurgling at toilets with slow drains after a storm points another.

Common Gurgling Patterns and What They Suggest

To make the patterns easier to compare, it helps to organize them side by side. The following table synthesizes field observations with guidance from InspectApedia, Tankreline, Firstank, and university septic resources.

Gurgling pattern you notice |

Most likely zone to investigate |

Why professionals care |

Gurgling only while the well pump runs |

Well water level, suction piping, storage tank |

Suggests air ingestion from a low-yield well or suction leak, which can damage pumps and stress the tank |

Gurgling continues for close to a minute after the pump stops |

Check valve or foot valve, drop pipe |

Indicates water draining backward and re-triggering the pump, driving up wear and power use |

Gurgling and bubbling at fixtures whenever cold water runs |

Air pockets in pipework, loft or attic tanks |

Points to trapped air that can usually be bled, but may also signal venting issues |

Gurgling plus banging or rapid pump cycling near the pressure tank |

Pressure tank precharge, bladder condition |

Suggests waterlogging, incorrect precharge, or bladder failure, all of which can shorten system life |

Gurgling with popping or crackling inside an older storage tank |

Sediment and mineral buildup at the tank base |

Signals long-term scale accumulation that reduces efficiency and can lead to corrosion and leaks |

Gurgling in toilets and drains, especially after heavy rain or flooding |

Septic tank and drainfield, main sewer line |

Treated as an early warning for overloaded or failing wastewater systems and potential contamination |

You do not need to diagnose every detail yourself, but being able to place your gurgle into one of these patterns helps you have an informed conversation with your well contractor or plumber.

How a Water-Wellness Pro Systematically Checks a Gurgling Tank

When I am called out to a home where the storage or pressure tank has started gurgling, I follow a consistent series of observations, always starting with safety and listening before touching anything.

The first question is when the sound happens. I ask the homeowner to turn on and off a few fixtures while I stand by the tank, and I watch the pressure gauge. If gurgling lines up exactly with the pump motor running and stops immediately when the pump cuts off, that points me toward the well or the suction side. If the tank continues to gurgle for 45 to 60 seconds after the motor stops, I pay more attention to check valves and possible leak-back in the drop pipe because that exact pattern is a hallmark of failing foot valves described in technical case reports.

I also take note of whether the pump is short-cycling. A healthy system will typically run for a good part of a minute or more to bring the tank from cut-in to cut-out pressure, then rest for a while. When the motor is clicking on and off every few seconds, a waterlogged tank or incorrect precharge jumps to the top of the list. That is when the redpowermag-style procedure of draining the tank completely and checking precharge with an accurate gauge can be very revealing, although I recommend that homeowners leave that to a trained person because over-pressurizing a tank can create real hazards, as InspectApedia warns.

Simultaneously, I look at the bigger picture in the mechanical room. If the cold-water tank or nearby piping sits just upstream of treatment equipment and there is visible rust and scale around the inlet, then sediment-induced turbulence becomes a more likely contributor. Tankreline’s advice to drain, flush, and disinfect cold-water tanks once or twice a year is rooted in exactly this real-world buildup. In a system that has never been flushed, sediment is almost always part of the story.

Finally, I walk the home and listen at fixtures. If the tank itself seems reasonably quiet but the tub drain or toilet is gurgling, especially after storms, then my focus shifts to septic and sewer lines. That is where the storm-related overload scenarios from UF/IFAS and the drainfield failure signs described by Penn State Extension become highly relevant.

This methodical approach, anchored in sound patterns and operating behavior rather than guesswork, helps avoid unnecessary part swaps and keeps the focus on long-term water wellness instead of quick band-aids.

Maintenance Habits That Keep Tanks Quiet, Efficient, and Safe

Quiet tanks are very rarely an accident. In nearly all of the research and field anecdotes, the systems that stay calm and reliable share a handful of maintenance habits.

Regular flushing and sediment control come up repeatedly in guidance on both cold-water tanks and hot water heaters. Tankreline recommends draining, flushing, and disinfecting cold-water tanks once or twice a year to clear mineral buildup. Water heater experts from Tennessee Standard Plumbing to Smith’s Plumbing and All Pro Plumbing suggest annual or semiannual tank flushing to keep sediment from hardening into a permanent insulating layer that traps heat and causes rumbling and popping. The same principle applies to storage tanks feeding your filtration and hydration systems: the less sediment your tank has to churn around, the quieter and more consistent its operation.

Reasonable pressure management is the second theme. Firstank and MyBuilder both emphasize that banging pipes and noisy tanks are often pressure stories as much as they are mechanical stories. A functioning pressure-reducing valve where appropriate, properly sized and adjusted expansion or pressure tanks, and water hammer arrestors on long or fast-closing runs all help your system absorb sudden changes instead of turning them into noise and shock. The well forum example of correcting a tank’s precharge from 25 psi to a more appropriate 38 psi for a 40 psi cut-in illustrates how a simple pressure adjustment can transform behavior.

Thoughtful septic and drain care, while not directly about the potable tank, is the third pillar because it protects you from confusing and hazardous gurgles coming from the wrong side of the plumbing. University and industry septic guides recommend pumping septic tanks every few years depending on size and use, protecting the drainfield from heavy vehicles and deep-rooted trees, and being careful about what goes down the drain. These actions reduce the odds of drain gurgling from backups that can be mistaken for tank noises.

Tennessee Standard Plumbing, citing U.S. Department of Energy guidance, notes that well-maintained water heaters can use up to about 15 percent less energy and last longer than neglected ones. While that statistic comes from the hot water side, the principle carries over: any system where pumps and tanks are not fighting sediment, air, and pressure issues tends to operate more efficiently and with less stress. For a smart hydration setup that may include well pumps, pressure tanks, and filtration, keeping things quiet is often a sign that you are keeping them efficient too.

Finally, know where DIY ends and professional care begins. Many sources, from Any Hour Services on noisy water heaters to Max Comfort Heating and Air on gurgling air conditioners, caution against deep DIY repairs on pressurized or electrically powered equipment. Bleeding air at a faucet, visually checking that valves are fully open, or listening for patterns are usually fine homeowner tasks. Opening electrical covers, altering tank pressures, or replacing check valves at the well are better left to licensed pros who carry the right tools and safety training.

Short FAQ on Gurgling Water Tanks

Is occasional gurgling from my storage tank normal?

Short, infrequent gurgles right after a pump cycle or after plumbing work can simply reflect small air bubbles working their way out of the system. However, persistent gurgling every time the pump runs, gurgling that continues long after the pump stops, or gurgling combined with rapid pump cycling, pressure swings, or visible leaks should be treated as a warning sign rather than normal background noise. Technical sources on pressure and storage tanks consistently treat those patterns as symptoms of air ingestion, valve problems, or tank defects that deserve attention.

Can gurgling in the tank affect my drinking water quality?

The sound itself does not contaminate your water, but the conditions behind it sometimes can. For example, a well that is being pumped harder than it can sustain may start pulling in sediment and fine particles along with air, which can cloud your water and overwhelm downstream filters. A storage or pressure tank with a compromised bladder can shed rust and debris, and a septic system that is gurgling into drains can introduce serious contamination risks if backups occur. If gurgling is accompanied by changes in clarity, odor, or taste, have both the mechanical system and, where appropriate, the water quality evaluated.

Should I shut my system down if I suddenly hear loud new gurgling and banging?

If the new noise is accompanied by other concerning symptoms such as the pump motor starting every few seconds, visible leaks, obvious tank deformation, or sewage odors, it is wise to err on the side of caution. In those situations, many plumbing and well references recommend shutting off electrical power to pumps, closing the main water valve if you can do so safely, and contacting a qualified professional. InspectApedia specifically warns against “quick-fix” attempts like adding air to a pressurized tank without proper procedures, because over-pressurizing can cause short cycling, pump damage, or even a tank failure. A controlled shutdown followed by expert diagnosis is far safer than continuing to run a system that is clearly distressed.

Quiet plumbing is not just a comfort issue; it is an everyday health and reliability indicator for the water your household depends on. When your storage or pressure tank starts to gurgle, treat it as a conversation starter. Listen to when and where it happens, note the pattern, and bring in a professional if simple checks do not resolve it. A smart hydration system should be both clean and calm, and paying attention to the sounds it makes is one of the most practical ways to keep it that way.

References

- https://extension.psu.edu/five-basic-practices-to-protect-your-septic-system/

- https://ephidsweb.web.illinois.edu/files/pwc/hosted/6_Septic%20Tank%20Inspection%20and%20Trouble%20Shooting_Montana%20State%20University%20Extension%20Service.pdf?ver=2018-03-20-155705-380

- https://blogs.ifas.ufl.edu/mrec/2024/09/27/septic-system-overload-how-heavy-rainfall-affects-your-system-and-what-to-do/

- https://www.auscoplumbing.com.au/addressing-common-water-heater-noises

- https://anyhourservices.com/water-heater-noise-phoenix-plumbing-repair/

- https://www.tankreline.co.uk/post/why-is-my-water-tank-making-noise

- https://www.expresssewer.com/blog/why-is-my-water-heater-making-noise

- https://firstank.com/7-water-tank-noises-and-what-they-mean/

- https://inspectapedia.com/water/Water-Tank-Gurgling-Noise.php

- https://www.justanswer.com/plumbing/oqnoq-water-tank-making-lots-popping-sounds-when-use.html

Share:

Effective Methods to Calibrate Inaccurate Pressure Gauge Readings in Home Water Filtration Systems

Determining When Activated Carbon Filters Are Saturated: A Smart Hydration Guide