Why Fast Filter Changes Matter More Than You Think

In a modern home hydration system, the filter cartridge is quietly doing the hardest work. It traps sediment, chlorine byproducts, heavy metals, and microbes before they reach your glass. Over time that cartridge becomes a concentrated bundle of everything you do not want to drink. If it is not replaced on time, performance falls off, and the very system you installed for protection can become a weak link.

Filtration specialists in industrial sectors, such as Dutch Filtration, describe filtration as a critical step to control contaminants, protect equipment, and keep product quality consistent. They also point out that fine-filtration stages are not self-cleaning and rely on consumable cartridges that drive ongoing operating expenses. Home water systems are no different. Your cartridges are consumables, not permanent hardware.

Water treatment experts repeatedly stress that overdue cartridges are not just an inconvenience. Guidance on cartridge systems from residential and industrial sources including Pacific Water Technology, Keiken Engineering, and SFFiltech highlights several risk patterns. As cartridges clog, pressure drop climbs, flow slows, and users get frustrated. If the cartridge is left in service too long, captured contaminants can start to break through, so water quality gradually drifts back toward its untreated state. Articles on residential filtration cartridges also warn that exhausted media can harbor microorganisms and release previously captured heavy metals back into the water stream.

The Water Quality Association defines a nominal filter rating as one that removes at least about eighty five percent of particles at the rated size, while absolute-rated elements aim for approximately ninety nine point nine percent removal, often described as a three log reduction. Those efficiencies assume a cartridge in good condition, with appropriate flow and pressure. Once the cartridge is overloaded, all bets are off.

For home users, this leads to a simple reality. The health value of a filtration system is determined as much by how reliably you change cartridges as by the micron rating printed on the label. Rapid-change designs, whether twist-style or push-in-style, do not clean the water by themselves.

What they do is lower the friction of maintenance so you are more likely to replace cartridges on time, before performance or safety is compromised.

What Your Cartridge Filter Actually Does

Before comparing twist and push-in designs, it helps to understand what is happening inside the cartridge you are changing.

Filtration specialists describe filtration as forcing water through a porous medium to remove suspended particles. Cartridge filters are the compact version of that principle. A housing directs water through a replaceable cartridge that can be pleated, wound, melt blown, or membrane based. Suppliers such as Filtrationchina and Commercial Industrial Supply explain several common roles for these cartridges.

Sediment cartridges catch sand, rust, and silt. Depth-style cartridges made from melt blown polypropylene or wound string trap particles throughout their thickness, which gives them good dirt holding capacity. Pleated cartridges use folds to create a large surface area; that extra area allows them to capture more solids with a lower pressure drop. Industrial guidance from MAC Water Technologies notes that pleated cartridges can often remove three to five times more solids than comparable depth cartridges, provided the housing was designed for pleated elements and the flow rate per square foot of media, often called flux, is appropriate.

Activated carbon cartridges focus on dissolved contaminants. They adsorb chlorine, many disinfection byproducts, pesticides, and volatile organic compounds that affect taste and odor. Articles on residential and industrial use from SFFiltech and Keiken Engineering emphasize that carbon stages are often placed after sediment cartridges to protect the more delicate carbon block from clogging with sludge.

At the high-performance end, membrane and microporous cartridges use extremely fine pores to remove bacteria and even some viruses. Residential suppliers like Triflow describe multi-stage ceramic and carbon cartridges that can reduce heavy metals, microplastics, and pathogenic organisms while leaving beneficial minerals such as calcium and magnesium in the water.

Across all of these designs, a few engineering themes keep coming up in technical guidance. Surface area controls how much dirt a cartridge can hold before the pressure drop becomes unacceptable. Micron rating and pore structure determine which particle sizes are removed. And housing geometry plus end-cap design control how well the cartridge seals, which determines how much unfiltered water might bypass around the element.

Those last two points are where twist versus push-in rapid-change designs start to matter.

Two Rapid-Change Families In Plain Language

Filtration engineers do not usually talk about “twist” and “push-in” the way marketing teams do. Instead, they classify cartridges and housings by how they seal. A technical guide from Filtrasystems, for example, distinguishes between double open ended cartridges, where both ends are open and the housing provides the seal, and single open ended cartridges, where one end has a molded cap and seals directly into a socket.

Within single open ended designs, there are several end styles with direct relevance to rapid-change home systems. Type 222 ends use a pair of O-rings that seat into a matching socket in the housing, giving a push-in seal that resists bypass. Type 226 ends are often called sanitary cartridges; they use double gaskets like the 222 style but add locking fins that must be aligned and twisted into place, giving a very secure, locked connection. Flat-end and spear-end caps are other single open ended variants that are designed to sit or push into specific housings.

When you look at twist-style and push-in-style drinking water systems under the sink, you are essentially seeing consumer-friendly versions of these industrial sealing concepts.

Twist-style rapid change (rotational lock housings)

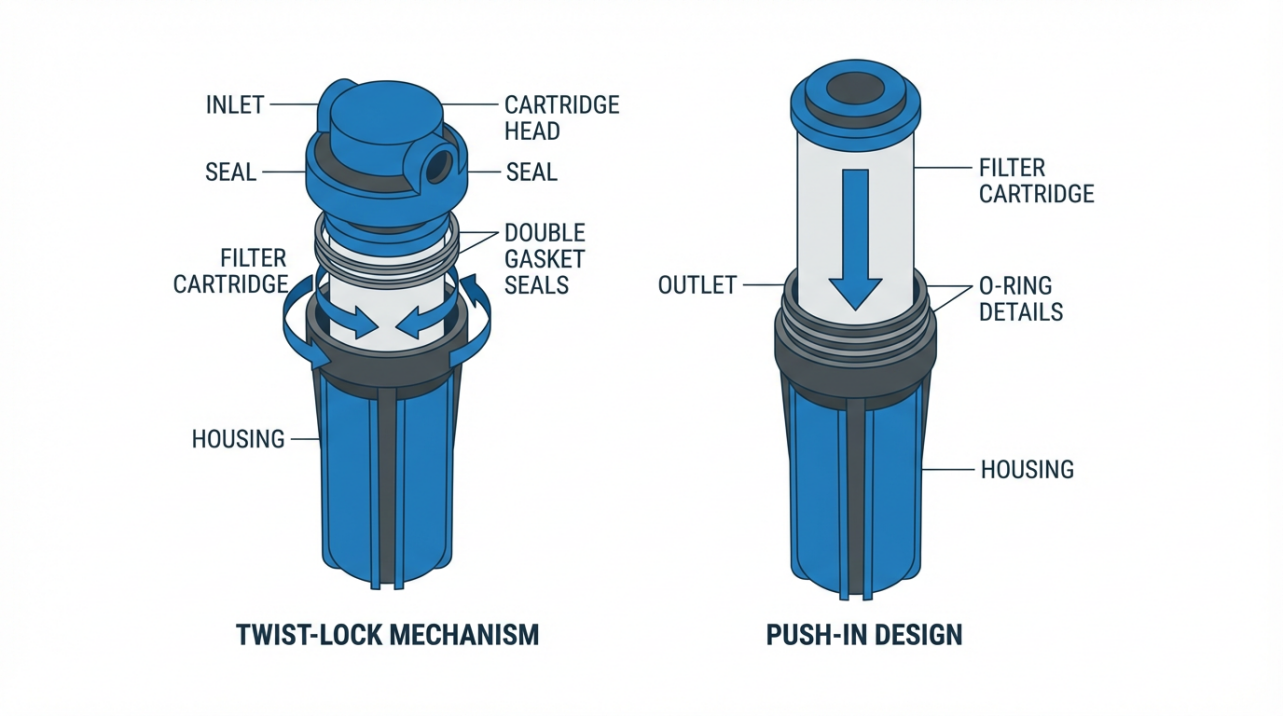

Twist-style systems typically mount a cartridge or a cartridge-in-head assembly that you release and secure by rotating it. Conceptually, this is similar to the 226 sanitary cartridges Filtrasystems describes, which align fins and then twist to lock into the housing, compressing double gaskets for a reliable seal.

In a home hydration context, a twist-style design often means you grasp the base of the filter, rotate a quarter turn, and drop the used cartridge out of the head. Installing a new cartridge is the reverse. Because rotation compresses the gasket or O-rings as it locks, these designs can achieve very robust seals with low risk of bypass. That is why twist-lock geometries are common in higher purity or critical filtration applications.

The tradeoff is that twist-style housings need enough clearance to rotate, and the interface needs to be designed so that users do not overtighten. Industrial guidance about sanitary 226 cartridges points out that alignment and twisting are important for proper sealing. In a cramped cabinet, you want to be sure you can complete that motion comfortably without stressing nearby tubing.

Push-in rapid change (single open ended drop-in designs)

Push-in rapid-change systems lean on the same sealing ideas behind Type 222 or flat-end single open ended cartridges. The cartridge has an end cap with one or more O-rings or a gasket. The housing or head has a matching socket. To install, you push the cartridge straight into the socket until it seats. To remove, you typically release a latch and pull downward.

Filtrasystems notes that single open ended designs with molded caps and double gaskets are widely used when bypass must be minimized. In residential systems, this style makes it possible to build very compact heads where cartridges insert vertically, without needing to unscrew or rotate the entire housing. That is especially attractive under shallow sinks or in tight utility closets.

As with any O-ring-based design, the quality of the seal depends on the condition of the elastomer and the precision of the molding. This is where guidance from MAC Water Technologies about matching cartridges to housings becomes critical. Their industrial advisory warns that swapping cartridge styles in housings designed for something else can reduce performance and raise operating costs. The same logic applies at home: a push-in head is engineered around a specific cartridge geometry. Using nonoriginal cartridges or forcing the wrong shape into the socket can compromise sealing and filtration.

How Fast-Change Design Interacts With Filtration Science

Connection style does not change the chemistry or physics of the media inside the cartridge, but it changes how the system behaves over time in everyday use.

Pressure drop and when you actually change the cartridge

Pacific Water Technology publishes sediment filter guidance showing how flow rate and micron rating interact. Finer cartridges provide better clarity but clog faster and generate more pressure drop. Their example data for pleated nine and three quarter inch by two and a half inch cartridges show flows around three gallons per minute for a one micron absolute cartridge increasing to about ten gallons per minute for a fifty micron element. They also note that as cartridges load with solids the pressure drop climbs, and that a differential pressure on the order of ten pounds per square inch is a common indicator that a cartridge should be replaced.

MAC Water Technologies frames the same concept using flux. The higher the flow per unit of filter area, the faster the media plugs. Using a pleated cartridge rather than a low surface area depth cartridge allows higher flows at the same pressure drop or longer life at the same flow.

Rapid-change housings matter here because they control how easy it is to respond when you see symptoms of a loaded cartridge, whether that is a pressure gauge creeping up or your shower flow starting to drop. Premier Sales, in their comparison of whole house cartridge versus backwash tank systems, emphasizes that cartridge systems rely on simple, periodic replacement to ensure consistently high performance. If a twist or push-in design reduces the time and mess of a changeout to a quick, tool-free motion, homeowners are far more likely to act promptly instead of postponing.

Leakage, bypass, and seal integrity

Filter designers worry about bypass: water sneaking around the outside of a cartridge rather than through it. That creates a short circuit for contaminants. Filtrasystems contrasts double open ended cartridges, where the housing must provide the seal, with single open ended cartridges, where molded end caps and double gaskets can make bypass essentially impossible when correctly installed. Their Type 222 and 226 designs illustrate how much engineering goes into seemingly simple end caps.

In practice, both twist-style and push-in-style rapid-change systems can be designed with very low bypass risk. Twist systems that compress gaskets as they lock can create a very positive, repeatable seal, provided the user aligns and rotates the cartridge fully. Push-in systems that use high quality O-rings seated in precision sockets can do the same, with less user effort.

Where problems arise is when cartridges and housings are mismatched or seals are neglected. Industrial advisors like MAC Water Technologies caution against dropping a cheaper depth cartridge into a housing designed for a pleated element because the surface area and flow profile change dramatically. In home systems, a similar issue appears when generic replacement cartridges do not replicate the sealing geometry of the original.

Whether your system is twist or push-in, using cartridges engineered for that specific head, and keeping O-rings clean and lightly lubricated with manufacturer-approved lubricants, is more important than the choice between rotational and linear motion.

Twist vs Push-In: Practical Pros And Cons

From a smart hydration perspective, the value of rapid-change designs is measured in fewer skipped maintenance cycles, less mess, and more consistent water quality. Within that lens, twist and push-in designs offer slightly different strengths. The table below summarizes key contrasts in everyday language, drawing on industrial sealing concepts from Filtrasystems and maintenance themes from MAC Water Technologies, Pacific Water Technology, and others.

Aspect |

||

Basic motion |

Rotate the cartridge or cartridge head to unlock and lock, often a quarter turn. |

Push the cartridge straight into a socket until it seats, then pull to remove when released. |

Seal concept |

Often analogous to sanitary Type 226 designs that combine double gaskets with locking fins, relying on rotational compression for a very tight seal. |

Similar to Type 222 or flat single open ended designs that depend on O-rings or a gasket compressed in a socket for sealing. |

Bypass control |

Excellent when properly aligned and twisted fully, because the locking fins hold the gasket under consistent compression. |

Also excellent when O-rings fit precisely; however, performance depends heavily on cartridge geometry matching the housing. |

Ergonomics under the sink |

Requires enough clearance to grasp and rotate the cartridge or sump, which can be challenging in very cramped cabinets. |

Works well in tight vertical spaces because motion is straight in and out, with little need for side clearance. |

Maintenance cues |

The feel of the twist as you lock into place can reassure users that the cartridge is fully seated; misalignment is more obvious. |

Seating is usually signaled by a tactile or audible click; however, partially inserted cartridges may be less obvious without clear design cues. |

Compatibility considerations |

Often uses proprietary heads and cartridges; mixing cartridge families can affect how gaskets compress and risk leaks. |

Also depends on proprietary geometry, particularly O-ring size and location; using nonmatching cartridges can compromise sealing. |

For most households, both designs can be highly effective when properly engineered and installed. The pros and cons are less about pure filtration performance and more about how the cartridges fit into your space, how intuitive the motion feels to you or to the person who will actually do the maintenance, and how easy it is to source correctly matched replacement cartridges.

Choosing The Right Rapid-Change Design For Your Home

When you work through real-world scenarios, the choice between twist and push-in starts to clarify.

If you have standard municipal water with relatively low sediment, technical guidance from Pacific Water Technology suggests that a one to five micron sediment stage followed by carbon is usually sufficient for point of use drinking water. In that situation, you are changing cartridges on a schedule driven more by taste, odor, and recommended service intervals than by heavy sludge. Either twist or push-in can work well. Ease of reaching the system under your sink and the availability of certified replacement cartridges become the dominant decision factors.

If your home relies on a private well, surface water, or a small community system with higher turbidity, the filtration chain is more complex. Pacific Water Technology and Keiken Engineering both note that in high-sediment or high-turbidity situations it is common to use multiple stages. A coarse stage protects a finer cartridge, and both may be installed ahead of membrane processes such as reverse osmosis. In those stacked systems, you may be servicing more than one cartridge at a time. A compact push-in vertical head that lets you swap cartridges quickly without a wrench can make it less tempting to “do it next month.” On the other hand, if you are dealing with very fine polishing stages, a twist-style sanitary lock modeled on Type 226 geometries can offer extra confidence that there is no bypass around your tightest element.

Household water demand also matters. Premier Sales points out that whole house cartridge systems must handle the needs of large families or multi bathroom homes. If your filtration system feeds showers, laundry, and kitchen fixtures, you may prefer housings that accept high flow cartridges, such as the six and a half inch diameter by forty inch elements Filtrasystems describes, which can handle flows in the hundreds of gallons per minute. In that larger format, commercial style twist-lock or clamp ring housings are more common than small push-in heads.

Space constraints are another practical consideration. Many modern apartments and compact homes have very shallow under-sink cabinets. If you cannot rotate a full housing without bumping plumbing, a slim push-in head with cartridges that drop straight down can make the difference between a realistic maintenance routine and something you dread. Pool industry experience summarized by Splash Fiberglass Pool Company illustrates how much adoption improves when cartridge maintenance is as simple as removing the element, hosing it off, and reinserting it. The same user psychology applies to drinking water filters.

Finally, consider who will be doing the work. Landscape irrigation experts interviewed by Landscape Management emphasize that easy maintenance, durability, and compatibility are the key traits professionals look for in filter cartridges. In a home, an older family member, a nontechnical partner, or even a teenage child may be the one swapping filters while you are traveling. Designs with clear orientation, minimal force, and obvious feedback when a cartridge is seated correctly tend to win in those situations, regardless of whether they twist or push.

Maintenance Habits That Matter More Than Connection Style

While it is natural to focus on the twist versus push question, long term water quality is driven by broader maintenance habits that every homeowner can control.

First, match the cartridge to your water. Articles on cartridge selection from SFFiltech, Triflow, and MAC Water Technologies all stress the importance of understanding what is in your water. If chlorine and taste are your main issues, an activated carbon stage is essential. If you are dealing with heavy metals, you may need specialty media such as those used in dedicated limescale and metal reduction cartridges. If microbial risk is high, ceramic or microporous cartridges with absolute ratings and multi log pathogen reduction are appropriate. A rapid-change head only helps if the media inside is chosen correctly.

Second, respect flow and pressure limits. Pacific Water Technology provides example flow capacities for common cartridge sizes along with warnings that pushing too much water through a small, tight cartridge leads to high pressure drop and short life. MAC Water Technologies defines flux as flow per unit area and shows that undersized cartridges in high flux applications clog quickly and can even develop channels that let particles pass. If your household demand is high, choose housings that accept larger cartridges or multiple parallel elements, regardless of whether they twist or push in, so that each cartridge operates within its comfort zone.

Third, replace cartridges on time. SFFiltech’s overview of drinking water cartridge types highlights that activated carbon elements typically need replacement about every six months, many microporous elements are intended for six to twelve months of service, and ceramic cartridges are often rated for one to two years. Triflow’s guidance for specialty limescale cartridges recommends six month replacement with warranty conditions tied to that interval. Pool-focused experts recommend cleaning pool cartridges every few weeks and replacing them every one to two years. The exact interval for your home hydration system will depend on your water quality, usage, and cartridge design, so follow the manufacturer’s instructions, but treat those intervals as part of your health routine rather than as suggestions to stretch indefinitely.

Fourth, monitor performance. One advantage of cartridge filtration highlighted by Dutch Filtration is that filters act as process monitors. When a cartridge plugs much faster than expected, it can indicate an upstream issue. In a home, an unusually quick pressure drop or sudden flow loss might signal construction up the street, changes in well water, or issues with pre-filtration. Rapid-change housings make it easier to inspect and, if necessary, upgrade cartridges in response to those changes.

Finally, use cartridges that are engineered for your head. MAC Water Technologies warns industrial users that substituting cheaper cartridge styles into housings designed for pleated high area elements is a common source of poor performance and higher operating costs. That advice translates directly to twist and push-in home systems. A cartridge that “almost fits” may not seal correctly, may lack the surface area your system was designed around, and may shorten maintenance intervals. When in doubt, choosing cartridges from suppliers that specify compatibility with your exact head design, and that publish clear micron ratings and performance data, is a safer path than chasing the lowest purchase price.

Closing Thoughts

Twist-style and push-in rapid-change designs are both proven ways to make filter changes less of a chore and more of a quick, confident habit. The science behind your cartridge media and the consistency of your maintenance routine matter far more than whether you rotate or push to lock a new filter into place. When you pair well chosen media with a connection style that fits your space and your hands, you make it much easier to keep every glass of water in your home reliably clean, clear, and pleasant to drink.

References

- https://www.sffiltech.net/a-what-you-need-to-know-types-and-importance-of-water-filter-cartridges.html

- https://www.landscapemanagement.net/recommender-what-should-pros-know-to-select-the-correct-filter-cartridges-for-their-needs/

- https://www.slideshare.net/slideshow/filtration-249435263/249435263

- https://www.macwatertechnologies.com/selecting-filtration-cartridges

- https://www.carter-wilson.com/blog/464-what-types-of-industrial-filters-meet-your-needs

- https://pacificwater.com.au/selecting-sediment-filters-domestic-rural-water-filtration/?srsltid=AfmBOop7hk8d4HBAne55QnYDVJlATH5XnMy1-0jFb6P3uVt7yN6aV7hW

- https://dutchfiltration.com/how-to-select-a-filter/

- https://www.filsonfilters.com/how-to-choose-a-filter-cart/

- https://filtrationchina.com/blog/what-is-cartridge-filter.html

- https://www.keiken-engineering.com/news/the-advantages-of-using-cartridge-filters-for-pre-filtration-process

Share:

Understanding the Need for Solenoid Valves in RO Systems

Understanding How Much Chlorine Your RO System Can Really Handle