As a Smart Hydration Specialist, I spend a lot of time looking at one quiet hero inside home water systems: the activated carbon filter. When it is fresh, it strips chlorine, off‑tastes, and many organics out of your water so effectively that you forget it exists. When it is saturated, it can quietly stop protecting you, and in some cases even start releasing what it once captured. Understanding when your carbon filter is truly “spent” is one of the most important habits you can build for healthy home hydration.

This guide walks you through what saturation really means, how to recognize it from real‑world symptoms, what timelines are realistic in a home, and how professionals judge saturation in critical applications. Along the way, I will connect home practice with the science used by organizations such as VITO, Suez, Labconco, and the U.S. EPA, and with practical guidance from water‑treatment manufacturers and air‑quality specialists.

What “Saturated” Really Means Inside An Activated Carbon Filter

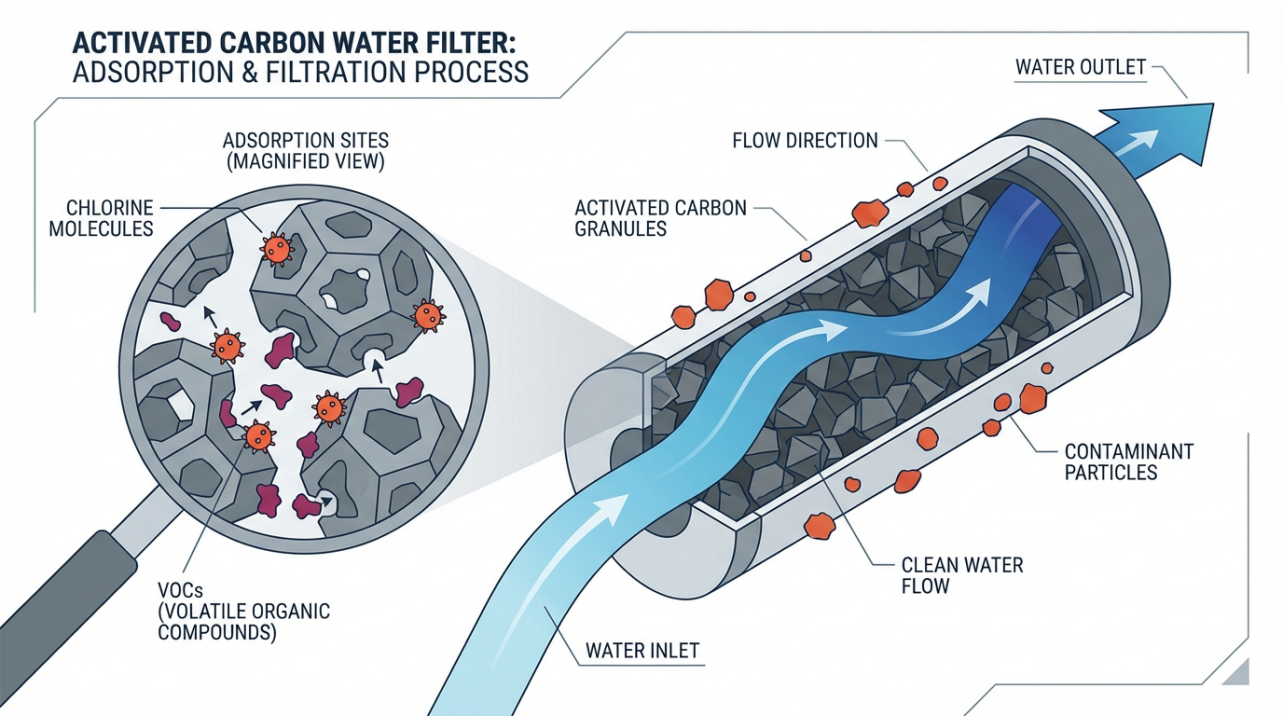

Activated carbon is not a sponge in the classic sense. Technical references from VITO and Suez describe it as a microporous carbon matrix with an enormous internal surface area, often hundreds of square meters per gram. That internal surface is covered with sites that contaminants can cling to. When water passes through, chlorine, many volatile organic compounds (VOCs), taste and odor compounds, and some other molecules attach to those sites in a process called adsorption, not absorption. They form a thin layer, sometimes called an adsorbate film, on the carbon surface.

A carbon bed does not fill up uniformly. The EMIS/VITO fact sheet on activated carbon adsorption explains that an “adsorption zone” forms and gradually moves through the bed. Near the inlet, carbon is fully saturated; near the outlet, it may still be fresh. As the zone moves and eventually reaches the outlet, the filter stops reliably holding contaminants. That is breakthrough: the point at which contaminants you wanted to remove start showing up again in the treated water.

Industrial guidance from the EPA on carbon adsorbers uses a few terms that are useful even at home. Saturation capacity is the absolute maximum the carbon could hold. Breakthrough capacity is the practical loading at which outlet contaminant levels become significant. Heel capacity is what remains stuck in the carbon even after regeneration. Working capacity is the useful middle slice, typically about 10 to 20 pounds of contaminant per 100 pounds of carbon in air‑pollution systems. In water, the numbers differ, but the principle is the same: only part of the theoretical capacity is truly “safe” to use.

Labconco’s carbon filtration guidance makes the same point in more practical terms. They show a filter that is theoretically able to hold about 32 milliliters of a solvent like xylene on a 100‑gram carbon bed, but they recommend using only about one‑third of this theoretical value for safety. In other words, even though the mathematics says the carbon could hold roughly 1.1 fl oz of that chemical, they treat it as if it can safely hold only around 0.4 fl oz. That one‑third rule of thumb exists because real life always contains variables: temperature, humidity, mixtures of different chemicals, and flow conditions all eat into your margin.

The same conservative thinking applies in drinking water. Manufacturers might rate a cartridge for a certain number of gallons or months, but heavy usage, poor source water, or high chlorine can consume working capacity faster than the label suggests. That is why practical signs of saturation matter just as much as any calendar date or gallon number.

Real‑World Symptoms Your Home Water Carbon Filter Is Spent

In homes, no one is sampling carbon and running iodine tests the way a Suez or Keiken lab might. Instead, your body, your faucet, and your appliances become the indicators. Several water‑treatment companies and service providers converge on the same set of tell‑tale symptoms: changes in taste, smell, and appearance, reduced flow, and equipment behavior.

Taste, Smell, And Appearance Start To Drift

One of the strongest everyday saturation cues is your senses. Cleantech Water and Pristine Water Softeners both highlight changes in taste and odor as early warning signs. When carbon is fresh, it strips out chlorine and many odor‑forming organics. As it saturates, those compounds begin to slip through.

If your municipal water is chlorinated, a faint pool‑like smell returning at your kitchen tap after months of clean, neutral‑tasting water is often a sign the carbon is no longer keeping up. An Arizona plumbing service points to metallic tastes and “weird” smells as signs that dissolved iron or other minerals and organics are no longer being held back effectively. In well‑water homes, cloudiness or a rusty tint tied to ferrous iron is another cue: good carbon and pre‑filtration should keep that out of your glass.

Air‑quality references echo the same pattern. Breathe Naturally notes that when activated carbon filters in air purifiers are spent, smoke and chemical odors start to reappear. SmartAir recommends a simple “smell test” for carbon air filters: if the filter itself smells strongly sour or chemical when you sniff it up close, it is likely saturated. That is air, not water, but the underlying metric is identical: when your nose starts detecting what carbon used to trap, the bed is losing working capacity.

A simple real‑world example helps fix this.

Imagine your kitchen tap has been odor‑free for six months. One week you notice a clear chlorine smell when you run the cold water for a drink, even though your city has not announced any treatment change. If that smell persists day after day, it is reasonable to treat your carbon cartridge as at or near saturation, even if the calendar says you still have time left.

Flow Slows Down And Equipment Feels “Sluggish”

Flow and pressure are the second major set of clues. Cleantech Water and Dubaopump emphasize that as carbon pores and the spaces between granules fill with trapped material, hydraulic resistance rises. In simple terms, the water has a harder time pushing through. The result is a noticeable drop in flow rate at the faucet or shower, or longer fill times for your refrigerator dispenser.

Hard water accelerates this effect. A plumbing article on filter replacement notes that high calcium and magnesium content can leave mineral scale inside the cartridge, compounding clogging from sediment and organic matter. You may also see other hard‑water clues at the same time, such as spots on clean dishes, mineral stains on clothes, or a filmy feel on your hands after washing. When these show up together with reduced flow at a filtered tap, a saturated or clogged carbon stage is a prime suspect.

In industrial and HVAC systems, engineers track the same phenomenon. Lyusen, an activated carbon filter manufacturer for air systems, describes monitoring “wind resistance.” As particles and moisture accumulate, the pressure drop across the filter increases, air volume falls, and fan noise often rises. Fram’s guidance on dirty cabin air filters in cars describes the same symptoms: reduced airflow from vents and a struggling HVAC blower. In water, we see the equivalent as a pump or booster that cycles longer and more often to deliver the same amount of water through a clogged carbon bed.

For a concrete home example, picture an under‑sink system that used to fill a 16 fl oz glass in about 5 seconds. Months later, filling the same glass now takes 12 or 15 seconds, and hot and cold unfiltered taps elsewhere in the house have not changed. That kind of localized slowdown strongly suggests that the cartridge on that line is loaded or clogged.

Visual Clues And Carbon Fines In Your Glass

Some carbon filters give you literal visible clues. Just Plumbing notes that seeing black specks in your water can mean carbon granules have begun to break down or wash out. That does not always mean the filter is saturated chemically, but it does signal physical degradation and a need to inspect and probably replace that cartridge.

Air‑filter manufacturers add another visual cue. Breathe Naturally describes how carbon filters in purifiers gradually turn gray as they load with smoke and other organics, and Lyusen notes that granular carbon in air systems may lose its surface luster or shift from deep black to brownish or patchily discolored as it ages. While those examples are from air, the same chemistry is at work in water. When a transparent housing lets you see a carbon cartridge that has gone from crisp black to dull, mottled gray or brown, or you can see channels and clumps instead of a uniform bed, that cartridge is no longer in peak condition.

From a Hydration Specialist’s standpoint, I treat visible carbon fines in drinking water, obvious discoloration of a cartridge, or both taste change and flow reduction together as a “do not ignore” combination. Even if the manufacturer’s replacement date has not technically arrived, those symptoms justify proactive replacement.

Instrument Readings And When They Help

Some homeowners like data, not just senses. One metric that shows up in residential guidance is total dissolved solids (TDS). The Arizona reverse‑osmosis article suggests that an RO system should remove at least about 80 percent of TDS compared with feed water. If a TDS monitor shows that removal has dropped below that threshold, they recommend replacing filters.

The nuance here matters. Carbon alone does not typically remove a large fraction of TDS, and TDS meters do not directly measure chlorine or many organics. In RO systems, TDS is more a reflection of membrane performance, but a failing carbon pre‑filter that allows chlorine through will eventually damage that membrane. In that context, watching TDS over time can act as a lagging indicator that upstream components, including carbon, have not done their job.

Professional water and air engineers often use more direct analytical indicators. Yuan Li Carbonyl, for example, describes comparing contaminant concentrations in influent and effluent. When those numbers converge, carbon capacity is exhausted. Keiken and Suez both emphasize lab tests such as iodine number and dechlorination half‑value length to quantify how much adsorption power remains. These are beyond what most homeowners will do, but they reinforce the principle: when the difference between “before” and “after” shrinks, saturation is near.

Time And Usage: How Long Before Saturation In The Real World?

If you ask five manufacturers how long a carbon cartridge lasts, you will get at least five different answers. That is not because someone is hiding the truth; it is because lifespan genuinely depends on water quality, usage volume, filter design, and carbon quality. Still, there are reasonable ranges you can use as a starting point, backed by the sources above.

Pristine Water Softeners notes that most manufacturers recommend replacing activated carbon water filters roughly every three to six months or after a specified gallon throughput, especially for smaller cartridges. Dubaopump suggests changing carbon elements at least every six months. An Arizona plumbing guide advises changing activated carbon filters every six months to a year and cautions against using them for more than a year. A general home‑filtration overview from Pentair adds that many point‑of‑use carbon cartridges on faucets or pitchers are changed every two to six months, while whole‑house sediment and carbon filters may range from about three to twelve months, depending on usage and water quality.

On the other side, some references illustrate longer intervals for larger or special systems. Abhirowater mentions continuously operating carbon filters that run around the clock in some plants, where cartridges might be replaced every eighteen to twenty‑four months, with certain products lasting three to four years under tightly controlled conditions. In that same article, the suggested schedule for typical home sediment and two carbon filters is six to twelve months, with more frequent inspection under heavy use.

For air applications, which give another data point on how quickly carbon saturates in a high‑load environment, Breathe Naturally reports that many carbon air filters are replaced every two to three months, while CustomFiltersDirect notes that residential HVAC carbon filters are often rated for about three months of standard use, dropping to thirty to sixty days in homes with smokers, multiple pets, or strong chemical use.

These ranges can be summarized as broad, non‑binding guidance, always secondary to the specific instructions for your device:

|

System type |

Typical manufacturer range reported in sources |

When to favor the shorter end of the range |

|

Pitcher, countertop, and faucet carbon filters |

About 2–6 months or set gallons (for example, up to roughly 600 gallons) in guidance from Pentair and similar sources |

For heavy daily use, strong chlorine odor in source water, or early taste changes |

|

Under‑sink and RO carbon stages |

Around 6–12 months in guidance from Pristine, Dubaopump, Just Plumbing, and Abhirowater |

For large households, well water with more organics, or when protecting an RO membrane |

|

Whole‑house carbon filters |

Roughly 3–12 months for cartridges, with larger continuously operated beds sometimes running 18–24 months in plant‑type systems per Abhirowater and industrial guidance |

For high sediment or organic load, noticeable odor returning in multiple fixtures, or pressure drop across the filter |

One simple calculation shows why even a “large” gallon rating can be consumed quickly. Pentair notes that some point‑of‑use filters are rated around 600 gallons. If your family runs about 3 gallons per day through a filtered drinking tap for cooking and beverages, that is roughly 90 days, or about three months. Double that usage to 6 gallons a day, and the same filter’s rated volume is reached in about a month and a half, even if the calendar sticker says six months.

The message is straightforward: treat months and gallon ratings as upper bounds under “normal” conditions, not guarantees. When in doubt, your senses and flow, plus a biased‑to‑early schedule, are a safer guidance system than squeezing every last drop out of a cartridge.

Why Running On A Saturated Carbon Filter Is A Real Risk

It is tempting to think of a carbon filter as simply “less effective” after saturation, but not harmful. Unfortunately, several references suggest that overused carbon can become counterproductive.

Pristine Water Softeners points out that failing to replace saturated carbon on time risks both reduced contaminant removal and potential bacterial growth on the loaded media. Organic matter that has been captured can become food for microbes, especially in warm, stagnant areas of the system. Cleantech Water and Abhirowater both warn that long‑neglected carbon filters can clog, slow the machine, and in severe cases cause the unit to jam or stop, which adds mechanical stress and repair cost.

A video‑based explanation of activated carbon saturation likens a carbon bed to a parking lot. Once all the adsorption “parking spots” are filled, new molecules cannot find space and simply pass straight through. Worse, the jostling caused by fresh contaminants bumping into older ones can dislodge previously adsorbed compounds, releasing them back into the water. Abhirowater explicitly notes that saturated filters can become ineffective or even counterproductive, and an air‑filter primer from Breathe Naturally observes that fully saturated carbon may lead to reemergence of smoke and chemical odors indoors.

In industrial practice, organizations such as Lyusen and Labconco treat saturation as a safety issue, not just a performance issue. Labconco describes “displacement” effects, where chemicals with higher affinity for carbon can push off weaker‑adsorbed compounds. If the displaced chemical has a low exposure limit or higher toxicity, it can leak into the workplace air even when total loading is within theoretical capacity. Lyusen warns that extended use in humid, heavily polluted environments not only eliminates purification but can also pose secondary‑pollution risks.

The same physics applies in drinking water, even if the specific contaminants differ. Running a carbon cartridge years past its intended life may mean that chlorine, disinfection byproducts, or taste‑ and odor‑forming compounds are no longer being controlled. In a worst case, organics that were once trapped may leach out in higher bursts. From a wellness perspective, it makes very little sense to invest in a filtration system and then gamble with a borderline filter to save a few dollars per year.

How Professionals Detect Saturation (And What You Can Borrow At Home)

In critical applications, engineers do not guess about saturation. They monitor.

For air and gas streams containing hydrogen sulfide, Carbon Filtration Solutions describes simple colorimetric “breakthrough indicators” mounted downstream of carbon beds. These indicators have a sorption layer and a color‑change sensor that flips from light blue to brown or black when hydrogen sulfide starts breaking through, signaling that the filter is at or near saturation. Similar tailored indicators exist for other gases like ammonia, halogens, and formaldehyde. The beauty of these devices is that they require no power and are read visually: either the color has changed or it has not.

Labconco recommends two broad approaches in laboratories using ductless enclosures. One is manual detection with gas detector tubes: an air sample from the filter exhaust is drawn through a small glass tube that changes color when target chemicals are present above a certain concentration, indicating breakthrough. The other is automated sensor systems built into the enclosure that trigger an audible and visual filter‑saturation alarm when they detect contaminants downstream of the carbon bed.

Water‑treatment engineers evaluating activated carbon quality often rely on iodine number, adsorption isotherm tests, and dechlorination length, as described by Keiken and Suez. In these tests, carbon samples are challenged with known concentrations of iodine or chlorine, and the amount removed and the bed depth required to halve chlorine concentration are measured. A carbon with a high iodine number (for example, around 800–1,200 mg per gram in Keiken’s guidance for water treatment) and a short dechlorination half‑value length has a higher and more efficient adsorption capacity.

Yuan Li Carbonyl adds a further dimension with iodine number trends, BET surface area measurements, and influent/effluent concentration comparisons. A falling iodine number or shrinking difference between inlet and outlet contaminant levels signals progressive saturation, even if the bed still flows well.

For a homeowner, these instruments are overkill. The practical lessons to borrow are simpler. First, professionals never rely on time alone; they pair calculated capacity and operating hours with actual performance indicators. Second, they design alarm points before full saturation, not at the last possible moment. Translating that to a home system, it is wise to pick a conservative replacement interval based on your manufacturer’s guidance and your usage, and then be prepared to replace sooner if you see taste, odor, or flow changes.

Building A Practical Replacement Plan For Your Home

Turning all this science into an easy routine is where water wellness becomes manageable instead of overwhelming. Here is how I recommend homeowners approach carbon saturation in their hydration systems, drawing on the sources above and field experience.

Start by anchoring on the manufacturer’s schedule. Companies like Pristine Water Softeners, Pentair, Dubaopump, and Just Plumbing all emphasize that the instructions for your specific model come first. If your pitcher or faucet filter says two months or 40 gallons, or your under‑sink system specifies six to twelve months, treat that as your maximum, not your target.

Next, consider your usage and source water. If you are a family of four cooking and filling bottles from the filtered tap all day, your daily gallon use is much higher than that of a single person who only fills a glass a few times per day. If your supply is chlorinated and you can smell that chlorine at unfiltered taps, your carbon has to work harder than in a low‑chlorine system. Homes on well water often carry more organic matter and iron, again increasing the load. That is when guidance such as the three to six month range from Pristine and the “at least every six months” suggestion from Dubaopump become more relevant than twelve‑month upper bounds.

Then, build in a simple sensory check habit. Take one week each month or quarter and consciously notice your filtered water’s smell, taste, and clarity. Compare the flow at your filtered tap to an unfiltered tap. If you have an RO system, glance at the TDS reading if one is available, remembering that sharply rising TDS over time may indicate troubles upstream. This does not require lab training; it just requires attention.

Finally, record your changes. Lyusen recommends maintaining a replacement ledger for large air systems, and the same advice applies at home. Write the installation date of each cartridge on the housing with a marker or keep a small note in your phone. That habit protects you from the very common situation highlighted by Just Plumbing, where a homeowner admits they cannot remember the last time a filter was changed. When you cannot recall, you are often already late.

A short example can illustrate how this plays out. Imagine a family using an under‑sink carbon filter rated for 600 gallons or six months, whichever comes first. They estimate their filtered water use at about 3 gallons per day. At that rate, they reach 600 gallons in roughly 200 days, which is a little over six and a half months. They decide to replace the cartridge every five months instead, building in a safety margin and accounting for days with heavier use, like holidays and hosting guests. Each month, they spend a moment noticing taste and flow. If those cues change noticeably in month four, they do not wait for month five. If they do not change at all, the cartridge still comes out at the five‑month mark. That is a practical, science‑aligned way to stay comfortably ahead of saturation.

FAQ: Common Questions About Saturated Carbon Filters

Can I just clean and reuse a carbon water filter instead of replacing it?

Several articles describe ways to rinse and even heat activated carbon to freshen it. For example, one guide from Living Whole suggests gentle rinsing, soaking in mild acidic solutions like lemon water, and even heating at around 250°F to drive off certain organics, and Abhirowater mentions reusable charcoal elements that can last up to about three years if cleaned every two to three months and oven‑dried around 210–212°F. However, Pristine Water Softeners and CustomFiltersDirect both stress that most consumer carbon cartridges are not designed to be fully restored by cleaning, and their adsorption capacity does not return to new. For sealed cartridges in pitchers, faucets, refrigerator filters, and typical under‑sink systems, the safest assumption is that they are replaceable, not regenerable. Cleaning may unclog some pores and improve flow temporarily, but it does not reset the chemical “parking lot” inside the carbon.

Is a TDS meter enough to tell me when my carbon filter is saturated?

Not by itself. TDS meters measure total dissolved solids, mostly salts and minerals. Carbon filters are primarily aimed at chlorine, many organic chemicals, and taste and odor compounds, which do not always shift TDS dramatically. In reverse‑osmosis systems, the Arizona guidance about maintaining at least around eighty percent TDS removal refers to the membrane’s performance, with carbon serving as a protector against chlorine. A decline in TDS performance there is meaningful, but for a simple carbon‑only faucet filter, a flat TDS reading does not guarantee that chlorine or VOC removal is still strong. Treat TDS as one piece of a larger picture, not a stand‑alone saturation detector.

What happens if I keep using a carbon filter for years?

The risk profile is twofold. First, removal efficiency declines, which means chlorine, disinfection byproducts, and various organic compounds may pass through at levels your system once reduced. Second, as Abhirowater and Pristine warn, long‑neglected carbon can host microbial growth and, in some cases, release previously adsorbed organics. In industrial practice, companies like Lyusen and Labconco treat overused carbon as a source of secondary pollution rather than a neutral bystander. At the home scale, the exact outcome depends on your water chemistry, but from a wellness standpoint, the stakes are high enough that multi‑year use without replacement is not a responsible choice.

As you think about your home hydration, remember that activated carbon is a powerful but finite resource. The science behind saturation is complex, yet the habits required to stay ahead of it are simple: follow a conservative schedule, listen to your senses and your system, and respect that a filter quietly doing its job deserves timely replacement. When you treat your carbon filters with that level of attention, you unlock the consistent, great‑tasting, lower‑chemical water your body—and your home—truly thrive on.

References

- https://www.epa.gov/air-emissions-monitoring-knowledge-base/monitoring-control-technique-activated-carbon-adsorber

- https://wqa.org/wp-content/uploads/2022/09/2016_GAC.pdf

- https://www.netsolwater.com/how-to-calculate-filter-media-for-mgf-psf-ssf-dmf-and-acf-in-water-treatment-explain-in-detail.php?blog=4775

- https://abhirowater.com/when-to-change-your-activated-carbon-filter/

- https://www.cleantechwater.co.in/how-to-know-it-is-time-to-change-activated-carbon-filters/

- https://carbonfiltrationsolutions.com.au/carbon-saturation-indicators/

- https://www.dubaopump.com/info-detail/maintenance-and-replacement-cycle-of-activated-carbon-filter

- https://www.keiken-engineering.com/news/how-is-activated-carbon-made-and-methods-to-check-the-quality-of-carbon-active-para-tralamiento-de-agua

- https://www.labconco.com/articles/carbon-filter-capacity-is-my-filter-half-full-or

- https://pristinewatersofteners.com/activated-carbon-water-filters-lifespan-and-when-to-replace-them/

Share:

Understanding the Gurgling Sounds in Water Storage Tanks

Understanding Why RO Systems Occasionally Produce Backflow