When you rely on reverse osmosis for cleaner, better‑tasting water at home or in a small business, the membrane is your quiet workhorse. It is also the most expensive consumable in most RO systems. Manufacturers and service providers like Ion Exchange and Crystal Quest routinely see membranes last around two to five years when conditions are stable and maintenance is disciplined. The challenge is that many of us do not have stable source water.

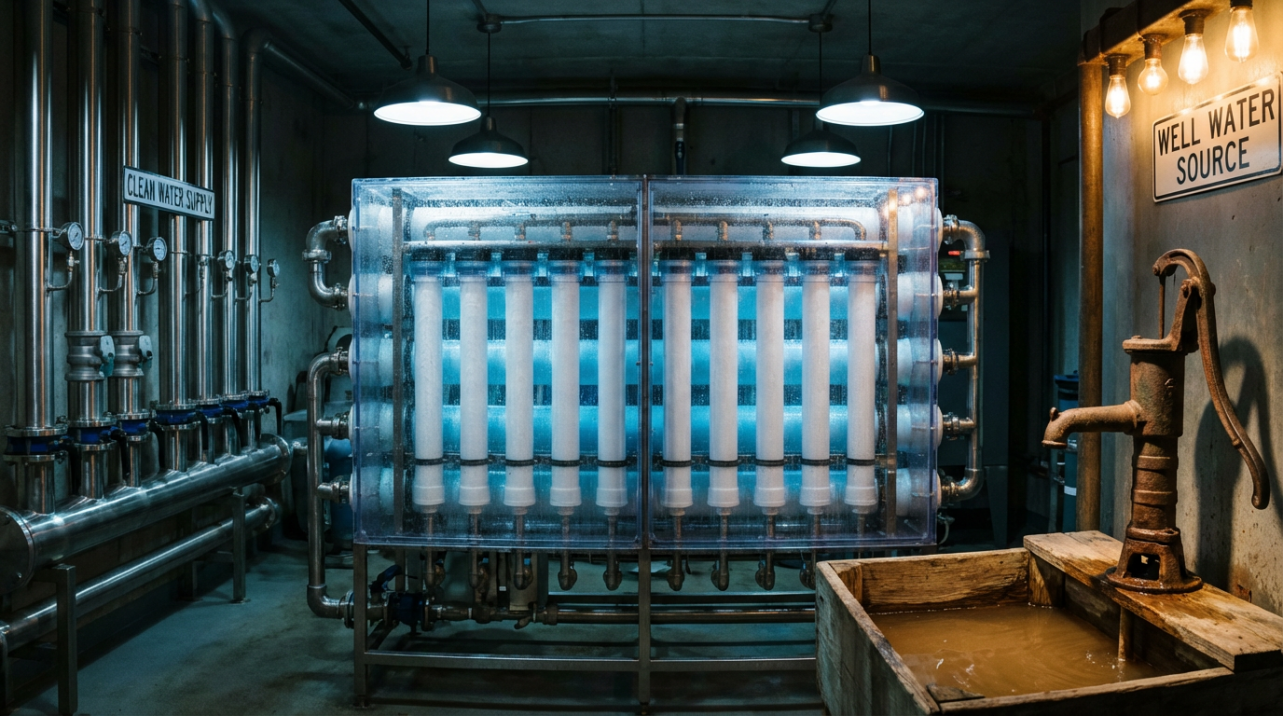

Maybe your home switches between city water and a backup well, your neighborhood supply changes seasonally, or your business draws from a surface source that turns cloudy after every storm. Those changing conditions are exactly what shorten RO membrane life and destabilize water quality if you treat the system as “set and forget.”

As a smart hydration specialist, I look at membrane protection as the foundation of whole‑home water wellness. The better you shield that thin‑film composite layer from shocks in water quality and operation, the more consistent and safe your drinking water stays, and the less often you pay for major replacements.

This guide walks through what actually harms RO membranes, why changing sources make things worse, and how to build a practical, science‑backed protection plan around pretreatment, operation, cleaning, and monitoring.

Why Changing Water Sources Are Hard on RO Membranes

At its core, a reverse osmosis membrane is a semi‑permeable barrier that lets water molecules pass while rejecting dissolved salts, metals, microbes, and other contaminants, as described by Ion Exchange and Axeon. In a perfect world, you would feed that membrane a steady, well‑conditioned water stream and operate it gently at design pressure and flow. The real world is rarely that kind.

When your source water changes, so does the chemistry hitting the membrane. City water often brings chlorine or chloramine to control microbes. Wells commonly bring hardness, iron, and sometimes hydrogen sulfide. Surface water can swing quickly in turbidity and organic content after rainfall. Each of those shifts moves the membrane from its steady operating point toward one or more of the classic failure mechanisms documented by Aqua Analytic, Axeon, and DuPont: fouling, scaling, chemical attack, and mechanical stress.

Imagine a household that uses municipal water most of the year and a shallow well during summer restrictions. In spring, the city might increase disinfectant dose, pushing more free chlorine toward the RO unit. In August, the well may be low and concentrated, with hardness and iron climbing. If pretreatment and operation stay unchanged, the membrane will see both stronger oxidation risk and stronger scaling risk in the same year. You may only notice subtle cues at the faucet: a slower flow, a shift in taste, or a TDS reading that never quite goes back to its old baseline after the season changes.

In industrial and high‑flow applications, Greenly and Kurita America note the same pattern on a larger scale. When operators do not adjust pretreatment and cleaning for seasonal changes in water, they see higher energy use, more frequent clean‑in‑place cycles, and premature membrane replacement.

To protect membranes in this kind of environment, it helps to understand what you are actually fighting.

The Four Main Things That Kill RO Membranes

Technical guidance from Aqua Analytic, Axeon, DuPont, and Water Online’s produced‑water case studies all point to four broad threats. Changing sources tend to amplify each of them.

Threat to membrane |

What it looks like in your RO |

Why changing sources makes it worse |

Key protections rooted in research |

Fouling (organics, biofilm, colloids) |

Gradual loss of permeate flow, rising pressure drop, sometimes slimy deposits on elements |

Spikes in organics or turbidity after storms or seasonal algae blooms overload pretreatment |

Robust sediment and multimedia filtration, optional ultrafiltration, timely CIP with alkaline and surfactant cleaners as recommended by Aqua Analytic and Kurita |

Scaling (hardness, silica, sulfates, metals) |

Declining flow, rising pressure, localized high‑TDS “hot spots” in permeate |

Switching from soft, low‑TDS water to hard or concentrated well water pushes salts past their solubility limit on the membrane surface |

Water softening, antiscalant dosing, and recovery limits as highlighted by Greenly, Crystal Quest, and Dultmeier |

Chemical attack (especially chlorine) |

Unusual increase in permeate flow, then loss of salt rejection; sometimes yellowed or brittle membrane surfaces |

City water may raise chlorine dose without notice; switching away from well water can suddenly reintroduce oxidants |

Generous activated carbon capacity, dechlorination dosing, and regular chlorine monitoring as recommended by Aqua Components, Crystal Quest, and Ion Exchange |

Mechanical and hydraulic stress |

Telescoping of elements, damaged seals, abrupt performance changes |

Rapid start–stop cycles or aggressive pressure changes during source switches strain the membrane and housings |

Following staged start‑up and shutdown procedures, using variable‑speed pumps, and preserving membranes during long outages as stressed by Reverse Osmosis Chemicals International and DuPont |

The rest of this article focuses on turning those high‑level threats into simple, routine actions that fit a busy household or small business.

Step 1: Stabilize the Water Before It Reaches the Membrane

All the major technical sources agree on one point: pretreatment is the single most powerful lever you have to protect an RO membrane. Aqua Analytic calls it the most important factor in membrane life, and Axeon lists it as a primary preventive strategy across residential, commercial, and industrial systems.

When water sources change, pretreatment needs to be designed for the worst‑case scenario, not the average day.

Build a Pretreatment Train for the Worst Water You Expect

At a minimum, most residential and light commercial RO systems include sediment and carbon filters before the membrane. Atlantic Blue Water Services and Culligan note that sediment filters are there specifically to trap dirt and silt so they never load the membrane, while carbon filters pull out chlorine and many organics that would otherwise cause both fouling and chemical attack.

Whole‑house systems described by Crystal Quest often go further. A typical setup may add larger sediment cartridges, proprietary multimedia filters that target chlorine, chloramines, heavy metals, pesticides, and volatile organic compounds, and in higher‑capacity units, dedicated carbon block filters for extra chlorine removal. Optional pretreatment depends on water analysis and can include water softeners, silica‑control systems, and iron or manganese filters.

For changing sources, it makes sense to design around the “worst” of each source. If your well has significant hardness and iron but no chlorine, while your city water has disinfectant but lower hardness, the pretreatment should still include both softening or antiscalant control and generous dechlorination capacity. That way the membrane never sees either hardness or chlorine spikes, regardless of which source is active.

Use Practical Targets: SDI, Hardness, and Chlorine

Aqua Analytic and Greenly both highlight the silt density index, or SDI, as a key design target for particulate control. Keeping SDI below about three to five helps keep fouling manageable and slows down the rise in transmembrane pressure. If you know your water tends to get muddy after heavy rain, that is a strong case for better upstream filtration or even ultrafiltration, because those spikes will push SDI upward.

For scaling control, Greenly suggests raw water hardness below about two hundred parts per million. If your hardness climbs higher than that when you switch to a seasonal well, you likely need a softener or a carefully dosed antiscalant to protect the membrane.

On the chemical side, nearly every membrane manufacturer and service article referenced, including Aqua Components, Crystal Quest, Ion Exchange, and Dultmeier, emphasizes that thin‑film RO membranes are highly sensitive to chlorine. They recommend either activated carbon or chemical dechlorination to make sure free chlorine is removed before the membrane. That becomes especially important when water suppliers adjust disinfectant dosing in response to weather, demand, or regulatory changes.

Replace Pretreatment Filters on Time

Even well‑designed pretreatment does not help if cartridges and media are exhausted. Residential guidance from Atlantic Blue Water Services, Crystal Quest, and Culligan generally converges around sediment and carbon filters lasting roughly twelve to twenty‑four months, with the actual schedule pulled forward for dirtier or more variable water.

Crystal Quest recommends watching for around a ten psi drop across prefilters as a performance‑based cue that it is time to replace them, and Greenly notes cartridge filter change when pressure drop exceeds about seven psi in industrial systems. If your feed water suddenly turns cloudy, you may hit that pressure drop faster, which is exactly the kind of early warning you want when sources are changing.

A simple example illustrates why this matters.

If a whole‑house RO skid costs a few thousand dollars and a sediment or carbon cartridge costs tens of dollars, replacing prefilters twice a year instead of once might add a modest amount to your annual budget. If that habit avoids even one premature membrane replacement cycle, the economics are squarely in your favor.

Consider Extra Barriers for Highly Variable Water

Axeon points out that adding upstream technologies such as ultrafiltration can dramatically cut RO cleaning frequency, sometimes by as much as half, by stripping out fine colloids and many microbes. Crystal Quest similarly offers optional softening, silica reduction, and iron removal filters ahead of RO for problem water.

For homes and small facilities that see dramatic swings in turbidity or biological content, adding one more barrier before the membrane can be a very cost‑effective way to stabilize conditions. Ion Exchange’s guidance for regions with diverse and seasonal water sources stresses tailoring pretreatment to the specific source profile, then adjusting maintenance as seasons shift.

Step 2: Operate the System Gently When Conditions Change

Even with good pretreatment, how you run the RO system strongly influences membrane life. Aqua Analytic, Axeon, Kurita America, and DuPont all emphasize stable, gentle operation: staying within design pressure, flux, and recovery, and avoiding sudden shocks.

Respect Pressure and Flow Limits

Crystal Quest whole‑house RO systems, for example, typically run with feed pressure around forty‑five to sixty psi, high‑pressure pump discharge around one hundred fifty to two hundred fifty psi, and permeate pressure roughly twenty to forty psi. Those ranges are chosen to balance permeate production, recovery, and membrane protection. If the feedwater TDS spikes when you change sources, you may be tempted to crank up pressure to maintain flow, but that move will increase mechanical stress and scaling risk on the membrane surface.

Kurita America and Axeon both highlight the need to maintain crossflow velocity across the membrane: enough flow to sweep away particles and salts, but not so high that you erode spacers or exceed element limits. That balance is especially important when water temperature and viscosity change seasonally, or when hardness spikes call for slightly lower recoveries to reduce scaling.

Follow Start‑Up, Shutdown, and Preservation Procedures

Reverse Osmosis Chemicals International provides detailed guidance that is directly relevant to changing sources and intermittent operation. They stress the importance of verifying pretreatment performance before start‑up, using correct start‑up sequences, and shutting down carefully to avoid damage. They also recommend that if an RO system will be off for more than about a day, membranes should be cleaned and preserved with appropriate solutions, because stagnant, nutrient‑rich water inside a stopped system is an invitation for bacterial growth and biofilm development.

In households, that scenario surfaces whenever people close a vacation home for a week or longer. In light commercial use, it might happen when a car wash or small plant shuts down for holidays. Preserving the membranes rather than simply turning off the pump can mean the difference between a smooth restart and a heavy biofouling problem.

Limit Rapid Cycling

Aqua Analytic notes that frequent start–stop cycles and sudden pressure changes increase mechanical stress on membranes. In systems that see fluctuating demand because of varying occupancy or production schedules, smart controls help. Greenly recommends variable‑frequency drives and automation that ramp pumps up and down smoothly, rather than using hard on–off transitions.

In a hydration‑focused home, you can support the same principle by avoiding unnecessary rapid faucet cycling, making sure storage tanks are properly sized so the system runs in reasonable duty cycles, and working with your installer to keep pressure spikes under control when the source changes.

Step 3: Clean the RO Membrane on Time, Not When It Is Too Late

Even with excellent pretreatment and careful operation, fouling and scaling are inevitable over time. The question is not whether the membrane will ever need cleaning, but when and how.

Use Performance‑Based Cleaning Triggers

Aqua Components, Greenly, Kurita America, and Water Online’s produced‑water case describe very similar cleaning triggers. The most common guidance is to initiate clean‑in‑place when normalized permeate flow drops by around ten to fifteen percent from its baseline, when differential pressure increases significantly, or when salt rejection declines.

Greenly suggests CIP for many industrial plants when permeate flow falls by about ten to fifteen percent, when differential pressure rises above about one bar across the membrane bank, or when salt rejection drops below roughly ninety percent. Kurita America and Water Online recommend cleaning when normalized permeate flow decreases by more than ten percent or when pressure drop or normalized salt passage increases by more than twenty percent, before fouling becomes so severe that it is hard to remove.

For a homeowner or small business, that might sound abstract, but it is easy to translate into a simple check. Suppose your under‑sink RO system normally produces about half a gallon per minute when the tank is mostly empty. If you notice that, under similar conditions, the flow plateaus closer to a little over a third of a gallon per minute and taste or TDS readings are creeping up, that is roughly a thirty percent decline, well beyond the ten to fifteen percent that industrial guidelines use as a cleaning trigger. At that point, cleaning or professional service is overdue.

Match the Cleaning Chemistry to the Foulant

Aqua Analytic, Axeon, Kurita, and the Environmental Engineering Research study on EDTA‑based cleaning all stress that successful membrane cleaning depends on correctly identifying the dominant foulant and selecting appropriate chemistry.

Acidic cleaners are typically used for mineral scales such as calcium carbonate, sulfates, and metal hydroxides. Alkaline cleaners, often with surfactants and chelating agents, target organics, biofilm, and many colloidal deposits. Kurita specifically warns against starting with strong acid on heavily biofouled membranes, because acid can compact and stabilize biological layers rather than removing them.

The Environmental Engineering Research study demonstrated that, for a particular organic fouling scenario, using a carefully optimized concentration of disodium EDTA at moderate temperature and flow restored around eighty‑six percent of the original flux. While that specific recipe is not something most homeowners will apply directly, it reinforces the point that tailored, science‑based cleaning is more effective and gentler on membranes than random mixtures or overly harsh acids.

Avoid Over‑Cleaning and Under‑Cleaning

In large produced‑water systems, Water Online reports that membranes typically tolerate about six to ten full chemical cleanings over a three to five year life, depending on how severe the feedwater is and how aggressively they are cleaned. That illustrates the trade‑off. Cleaning too rarely allows fouling to get dense and difficult to remove, which often forces more aggressive chemistry and increases the risk of irreversible damage. Cleaning too often exposes the membrane to chemicals and temperature cycles without enough benefit.

The sweet spot is performance‑based, not calendar‑based. In a home or small business, that translates to tracking flow, pressure, and TDS and working with your water professional to schedule cleanings or cartridge changes when those indicators move, rather than waiting for an arbitrary anniversary date or for water quality to become obviously bad.

Step 4: Monitor Water Quality and System Health in Sync with Source Changes

Technically strong sources from Axeon, Crystal Quest, Greenly, DuPont, Kurita, Dultmeier, and Culligan all converge on one message: data is your friend. Good monitoring turns a mysterious “black box” under the sink or in the utility room into a predictable, controllable process.

Focus on a Few High‑Value Parameters

For hydration‑focused homes, small commercial sites, and even many industrial operators, a short list of parameters covers most of what you need to protect membranes and water quality.

Parameter |

What it tells you |

Typical guidance from the sources |

Feed and post‑prefilter pressure |

Whether sediment and carbon stages are clogging |

Crystal Quest suggests replacing prefilters when pressure drop is roughly ten psi |

Differential pressure across RO |

Whether flow channels are plugging or surface fouling is increasing |

Greenly and Kurita recommend cleaning when normalized pressure drop rises significantly, often around one bar or when change exceeds around fifteen to twenty percent |

Permeate flow rate |

Overall membrane permeability and fouling level |

Aqua Analytic, Axeon, and Water Online recommend cleaning when normalized flow drops by about ten to fifteen percent from baseline |

Permeate TDS or conductivity |

Salt rejection and polishing stage health |

Greenly notes targets below about five hundred ppm for drinking water; Dultmeier flags spotting in car wash permeate when TDS rises above about forty ppm |

Silt density index (SDI) of feed |

Particulate fouling potential |

Aqua Analytic and Greenly target SDI below about three to five before RO |

In a home setting, a simple handheld TDS meter and attention to flow and taste get you surprisingly far. Dultmeier provides a clear, step‑by‑step procedure for taking accurate TDS readings with a handheld meter: use a clean sample container, rinse, collect permeate, immerse and swirl the probe, hold the reading, then record it. That is easy to replicate at the kitchen sink.

Sync Monitoring With Source Changes

The key with frequently changing water sources is timing. Greenly recommends testing feedwater at least quarterly and especially before seasonal changes, because even modest shifts affect chemical dosing and membrane performance. When you know your municipality changes reservoirs in spring or you switch to a backup well in late summer, that is the moment to check TDS, hardness, and possibly SDI, not six months later.

Crystal Quest encourages weekly checks of pressures and flows on whole‑house systems and monthly TDS testing. Culligan and Atlantic Blue advise setting reminders for filter changes and periodic tank draining. For a home where the source changes twice a year, a practical pattern could be weekly “quick looks” at flow and taste, monthly TDS readings, and more detailed checks the week before and after each planned source change.

A simple example: imagine your permeate TDS has held steady around fifteen ppm for months. After a switch to well water, it rises to twenty‑two ppm, and your flow seems slightly slower. That might still be within acceptable drinking‑water quality, but it tells you something has changed at the membrane. Combined with a small rise in differential pressure, it is an early cue to inspect prefilters and consider cleaning before performance drifts further.

Consider Light Automation Where It Makes Sense

Greenly and DuPont both highlight the advantages of automated monitoring and control, especially for larger systems: real‑time tracking of pressure, flow, and TDS, automatic flushing sequences, alarms for abnormal readings, and remote access. For a homeowner, that might translate into a smart whole‑house RO system with built‑in sensors and a maintenance alert feature. For a small business, it might mean adding simple pressure and flow transmitters tied into an existing control panel.

The goal is the same at any scale: catch changes early, respond based on data, and keep the membrane operating within its comfort zone even as the water source changes around it.

Real‑World Strategies for Variable Sources

Every installation is different, but the research‑backed principles above tend to show up in a few recurring scenarios.

Home Using Municipal Water With a Backup Well

Crystal Quest’s whole‑house systems and Atlantic Blue’s residential maintenance guidance are a good match for homes that normally use city water but keep a well in reserve. In this case, design pretreatment as if the well were always in use: adequate sediment removal for any iron or turbidity, softening or antiscalant to address hardness, and robust carbon filtration for the worst‑case chlorine or chloramine level.

Before switching to the well, plan a brief check of hardness, iron, and TDS. After you switch back to city water, test for chlorine breakthrough at the carbon outlet with simple strips. Replace filters when pressure drop and tests suggest it, even if the calendar says they “should” have more life. That combination of worst‑case pretreatment and source‑aligned monitoring greatly reduces membrane surprises.

Rural Well With Strong Seasonal Swings

In areas where wells experience seasonal drawdown, Ion Exchange’s emphasis on understanding the specific source and seasonal patterns is especially relevant. Hardness, iron, and even microbial content can rise as water levels fall. In that setting, take a cue from the Greenly and DuPont industrial recommendations by adjusting system recovery downward slightly during high‑risk seasons to reduce scaling, and by scheduling preventive cleaning just ahead of those periods rather than waiting for visible decline.

If heavy rains cause turbidity spikes, consider adding or upgrading multimedia filtration or ultrafiltration as Axeon suggests, so the RO membrane always sees a stable, low‑SDI feed even when the raw water is anything but stable.

Car Wash or Light Commercial System With Changing City Feed

Dultmeier’s guidance for car wash RO systems is a clear example of applying these principles in a commercial context. They stress weekly TDS checks on permeate, with around forty ppm as a practical upper limit before spotting becomes visible on vehicles. They also emphasize chlorine protection through carbon filters and full softening so hardness is essentially zero at the membrane inlet.

If a city supply changes sources or treatment strategies and TDS, hardness, or chlorine drift up, car wash operators who follow Dultmeier’s monitoring advice see the shift quickly and can adjust pretreatment or schedule membrane replacement before they lose customers to spotting. The exact same pattern applies in other small businesses where water appearance and taste matter, from cafes to dental clinics.

When It Is Time to Replace the Membrane Anyway

No matter how well you protect an RO membrane, it is still a consumable. Ion Exchange notes a typical lifespan of around two to five years depending on feedwater quality, loading, and maintenance. Residential guides from Atlantic Blue and Crystal Quest see many whole‑house membranes replaced about every two to three years, often as a full set. Dultmeier’s car wash guidance extends that range to about one to five years, reflecting the harsher conditions in high‑use systems. DuPont reports that well‑protected industrial membranes can last roughly six years.

The common theme is that actual life is determined less by the calendar and more by how stable and well‑conditioned the feedwater is, how gently the system is operated, how disciplined cleaning is, and how well pretreatment and monitoring handle any changes in source.

Signs that it is time to stop cleaning and start planning a replacement include persistent high TDS despite correct pretreatment and cleaning, permeate flow that never returns close to its normalized baseline after CIP, visible membrane damage on inspection, or a rising need for very frequent cleaning. Water Online’s produced‑water work suggests that once membranes have been through their design number of cleanings and still cannot maintain performance, periodic partial replacement of the most heavily loaded elements can be a cost‑effective step before a complete change‑out.

For a health‑focused home, the decision often comes down to whether the system can still deliver the level of purity and taste you expect without constant intervention. When it cannot, a new membrane becomes part of the broader investment in your household’s hydration infrastructure.

FAQ: Protecting RO Membranes With Variable Water Sources

Do I really need pretreatment if my tap water looks clear?

Clarity is not a reliable indicator of scaling or chemical risk. Research summarized by Aqua Analytic, Aqua Components, and Ion Exchange shows that hardness, dissolved metals, and chlorine can all be high in visually clear water and still damage membranes. Sediment and carbon filtration are considered minimum protection, and in many wells, softening or antiscalant dosing is also needed.

How often should I check TDS if my water source changes seasonally?

Guidance from Dultmeier, Crystal Quest, and Greenly suggests weekly to monthly checks as a reasonable starting point. In practice, weekly readings are ideal right before and after a planned source change or during known high‑risk seasons, because trends matter more than single numbers. The key is to establish a baseline and notice when values begin to drift.

Can an RO membrane really last five years or more if my water keeps changing?

Ion Exchange, DuPont, and several field case studies show membranes lasting several years in well‑managed systems, even with challenging water. The more variable your source, the more critical robust pretreatment, gentle operation, timely cleaning, and data‑driven monitoring become. Those practices do not guarantee a specific lifespan, but they significantly increase the odds that your membrane reaches the upper end of what manufacturers and service providers see in the field.

Protecting an RO membrane in the face of changing water sources is not about chasing perfection or obsessing over every reading. It is about building a smart, resilient setup: pretreatment tuned to your worst water, operation that respects the membrane’s limits, cleaning based on real performance, and simple monitoring habits that fit a busy life. Do that, and you give your family or business a stable source of clean, great‑tasting water while your membrane quietly does its job for years instead of months.

References

- https://www.energy.gov/femp/articles/reverse-osmosis-optimization

- https://www.eeer.org/journal/view.php?doi=10.4491/eer.2017.098

- https://www.dultmeier.com/how-often-should-you-change-your-ro-membranes-a-complete-guide

- http://reverseosmosischemicals.com/reverse-osmosis-guides

- https://aquaanalytic.ae/how-to-increase-the-life-time-of-reverse-osmosis-membranes/

- https://www.aquasana.com/info/3-tips-for-maintaining-a-home-reverse-osmosis-system-pd.html?srsltid=AfmBOooHhA2tfymoC_EVg2zjqz2p31pahHbTL4Ije94N3hAJ4VLVZdMQ

- https://chunkewatertreatment.com/ro-membrane-cleaning-techniques/

- https://greenly.co.in/how-to-optimize-an-ro-plant-for-long-term-efficiency/?srsltid=AfmBOoqpmzC7DozUiyhxN3uVJHA3WiRYVM6npyQu8hy6Nz0fbRkoi1pn

- https://www.culligan.com/blog/how-to-keep-your-water-filtration-system-working-properly

- https://www.dupont.com/knowledge/importance-of-industrial-ro-system-maintenance.html

Share:

Effective Pre-Treatment Solutions for Oil-Contaminated Water RO Systems

Effective Solutions for Low Water Pressure Areas Under 0.2 MPa