Reverse osmosis systems have earned their place in many kitchens because they do something simple yet powerful: they strip a wide range of contaminants out of drinking water. Studies highlighted by organizations such as the Water Quality Association and regional providers in states like Colorado and Hawaii show that a well-designed RO system can dramatically cut dissolved solids, heavy metals like lead and arsenic, and many chemical pollutants that simply glide past basic carbon filters.

What often gets far less attention is what happens after that purified water leaves the membrane. As a Smart Hydration Specialist and Water Wellness Advocate, I spend a lot of time under sinks and inside utility closets, and I see the same pattern: people carefully choose the filter technology, then barely think about backflow or siphoning. Yet a single backflow event can undo much of the safety you thought you were buying.

Anti-siphon features are the quiet bodyguards of your RO setup. They do not make the water taste better or change the numbers on a lab report, but they keep contaminated water from being pulled backward into your RO unit or even into your home’s potable plumbing. Understanding how they work, when codes require them, and how to choose between different options is an important piece of designing a safe, resilient drinking water system at home.

Why Backflow Protection Matters For Drinking Water

To understand anti-siphon features, you first need a clear picture of backflow. Irrigation experts define backflow as the unwanted reverse flow of water from a non-drinking system back into the main potable supply. It happens at “cross-connections” where drinking water lines meet irrigation pipes, hose bibs, or other non-potable plumbing. Two main forces can drive it: back pressure, when downstream pressure becomes higher than the supply, and back siphonage, when a drop in supply pressure creates a vacuum that literally sucks water backward.

Irrigation backflow is a vivid example. When a sprinkler system uses fertilizer injection or pesticides, a pressure drop in the street main or a nearby fire hydrant opening can pull that chemical-laden water back into the household plumbing if no backflow or anti-siphon device is installed. Resources from irrigation and valve manufacturers emphasize that this is not a theoretical risk. They describe contaminated irrigation water, fertilizers, and soil being pulled into water lines and creating significant health hazards.

Anti-siphon and backflow-prevention valves evolved to solve exactly this problem. Articles on anti-siphon valves explain that these devices stop reverse flow by either closing when pressure reverses or by admitting air into the line when a vacuum forms, which breaks the siphon. Glossaries from water and plumbing references highlight that building codes routinely require anti-siphon devices on hose bibs, outdoor faucets, sprinkler systems, and other cross-connections to protect drinking water from contamination and waterborne disease.

The same physics that causes irrigation backflow applies inside a kitchen cabinet. If your RO system is tied into the cold-water line and your sink drain, there is a cross-connection between potable water and potentially dirty or chemically contaminated water. Siphoning and backflow are rare events when everything is working perfectly, but they are exactly the kind of low-frequency, high-impact failures that smart water design tries to prevent.

How Residential RO Systems Move Water

Reverse osmosis technology is conceptually simple. Water is pushed under pressure across a semipermeable membrane that allows water molecules through but holds back most dissolved salts, metals, organic compounds, and many microorganisms. The Water Quality Association describes this as one part of a “multi-barrier” approach, often combined with sediment and carbon filters, and sometimes ultraviolet disinfection, to cover a broader spectrum of contaminants than any single method can handle alone.

Point-of-use RO systems usually sit under a sink or on a countertop. Typical under-sink units connect to the cold-water line, run water through pre-filters and the RO membrane, store purified water in a small tank, and send a separate concentrated waste stream to the drain. Case studies from communities like Aurora, Colorado, emphasize the value of this arrangement in places where run-off, industrial pollution, or aging infrastructure can introduce contaminants that municipal treatment and distribution do not fully control. For vulnerable people such as children, older adults, or those with weaker immune systems, adding RO at the tap can significantly reduce exposure to harmful substances and improve taste, which in turn promotes better hydration.

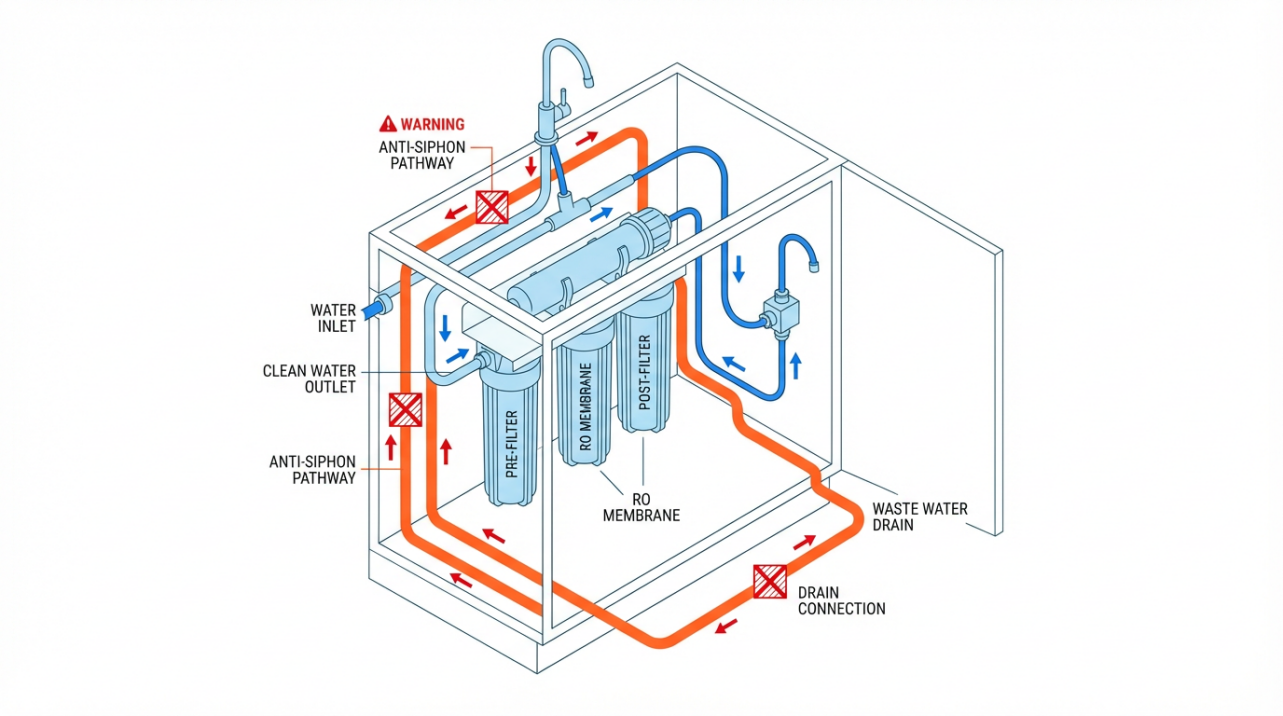

The moment you connect that RO system to both a potable water line and a drain, you have created several pathways where pressure changes could try to push or pull water in directions the designer never intended. Those are the places where anti-siphon and backflow protections earn their keep.

Where Siphoning Can Happen In An RO Setup

Back siphonage always needs the same conditions: a higher point and a lower point connected by piping, plus a pressure drop that lets gravity and vacuum do their work. In an RO installation, there are a few typical weak spots.

The drain line from the RO system to the sink plumbing is one. Industrial RO design literature documents problems when concentrate lines are routed to a drain below the membrane vessels without any automatic isolation or vacuum-breaking valve. In those cases, a shutdown or sudden pressure change can create a siphon that pulls a vacuum, drains the vessels, and even draws in airborne bacteria and fungi through couplings. When the system restarts, the accumulated air and sudden surge of water can cause water hammer strong enough to crack housings or damage internal supports.

In a residential system, components are smaller, but the principle is identical. If the RO drain line ties into a portion of drain piping that can flood or experience strong reverse flow during a blockage, a severe backup plus a missing or failed anti-siphon feature could allow dirty drain water to be forced backward toward the RO drain connection.

The supply side is another potential weak point. The same back pressure and back siphonage mechanisms that irrigation specialists worry about can exist anywhere a pump, elevated fixture, or sudden pressure drop is involved. If an RO unit, ice maker, or refrigerator line branches off the cold-water supply without adequate backflow prevention, a failure elsewhere in the system could pull RO reject water or external contaminants back into that branch.

Because water distribution networks experience unpredictable events, including main breaks and firefighting flows, and because wastewater plumbing can clog without warning, backflow protection is not something you can safely ignore and simply hope never happens.

What Anti-Siphon Features Actually Do

Anti-siphon features are a subset of backflow protection. Their job is to stop reverse flow specifically when suction or vacuum conditions appear, while many backflow preventers also guard against situations where downstream pressure simply becomes higher than upstream pressure.

Articles explaining anti-siphon valves describe them as safety devices that prevent siphoning, which they define as the unwanted reverse movement of liquids driven by pressure differences. Core components often include a check valve, diaphragm, spring-loaded mechanism, and an air inlet or vacuum breaker. Under normal pressure and forward flow, the valve stays closed to the air and open to water flow. When flow stops and pressure drops, the internal mechanism moves to admit air into the line, breaking the siphon and preventing contaminated liquid from being pulled back toward the source.

In plumbing, this protects hose bibs, outdoor faucets, bathtubs, and other fixtures where water can be submerged or exposed to contaminants.

In irrigation, anti-siphon sprinkler valves sit above the highest downstream sprinkler head so that if pressure in the supply drops, air can enter and stop soil, fertilizers, and pesticides from being siphoned into household or municipal water lines. Fuel systems in automobiles and generators use similar concepts to prevent fuel theft, leaks, and fire hazards when tanks are lower than engines or distribution lines.

Water industry glossaries point out that anti-siphon devices sit alongside related protective components such as check valves, backflow preventers, vacuum breakers, and air gaps. Many plumbing and building codes require one or more of these wherever potable water and non-potable uses intersect. The key idea in all of them is controlled, one-way flow: water or fuel should move forward on your terms and never be allowed to retreat when a vacuum appears.

In reverse osmosis systems, anti-siphon features are typically implemented in three ways: air-gap faucets, non-air-gap faucets that rely on check valves and plumbing design, and separate vacuum breakers or anti-siphon valves on drain or concentrate lines.

Anti-Siphon Features Commonly Used In RO Systems

Air-Gap RO Faucets

An air-gap RO faucet builds an anti-siphon device into the faucet itself. Instead of running the RO waste line directly to a drain saddle on the sink trap, the waste water first travels up to the faucet, discharges into an internal channel that is open to air, and only then drops down through a separate line into the drain. The vertical space between the outlet where waste water discharges inside the faucet and the point where it enters the household drain line is the air gap.

Research notes on RO faucets explain that this type of faucet usually has three tubes under the counter: one bringing purified water up from the RO system, one bringing waste water up from the RO module to the faucet’s air-gap chamber, and one taking that waste water down from the faucet into the sink drain. By interposing a physical air gap in the waste path, the faucet makes it impossible for a backup in the sink drain to push dirty water back into the RO module; any reverse flow would spill out at the air gap instead of reaching the RO equipment.

There are trade-offs. Air-gap faucets are often noisier. When the RO system is flushing concentrate to the drain, some homeowners notice a gurgling sound as water falls across the air gap and down the small drain tube. If the small drain port or line clogs, water may spill onto the countertop around the faucet rather than backing up silently. These behaviors are the flip side of a safety feature that is doing its job by refusing to let drain water push back toward the RO system.

Many plumbing codes that follow common U.S. model standards call for an air gap on under-sink RO systems, and an air-gap faucet is a straightforward way to meet that requirement using off-the-shelf parts.

Non–Air-Gap RO Faucets

Non–air-gap faucets look simpler under the counter. They usually have only one line for purified water from the RO system, while the waste line runs directly from the RO module to a drain saddle on the sink plumbing. Instead of providing a physical air gap, these setups rely on check valves and good plumbing practice to prevent backflow.

General research on RO faucets notes that non–air-gap designs are quieter in normal operation and are easier and faster to install, especially on tight or thick countertops. With fewer tubes and fewer small internal channels that can clog, they present fewer potential nuisance issues. These benefits explain why they are widely used wherever codes allow them.

The trade-off is a small but real risk. If the sink drain experiences a severe blockage at or below the point where the RO waste line ties in, and if a check valve somewhere in the waste path fails or is absent, contaminated water can be forced backward into the RO drain line. For that reason, some jurisdictions that adopt strict plumbing codes prohibit non–air-gap faucets for RO installations even though they remain popular in other regions.

From a health and safety perspective, non–air-gap configurations demand careful attention to code, manufacturer instructions, and ongoing maintenance of check valves and drain saddles.

Vacuum Breakers And Anti-Siphon Valves On RO Lines

A third way anti-siphon protection shows up is as a dedicated valve on the RO drain or concentrate line. Industrial RO design guidance warns about installations where the concentrate line runs from membrane vessels down to a drain at a lower elevation without any valve that can admit air under vacuum. During shutdown, this arrangement can let a siphon form that empties vessels, pulls air and microorganisms through couplings, and sets up violent water hammer on restart. To break that siphon, engineers recommend adding automatic isolation or vacuum-breaking valves on concentrate lines and using gaskets rated for vacuum service.

One specific safeguard described is teeing a lightly spring-loaded check valve, adjusted to open at only one or two pounds per square inch, into the top of the concentrate line. If a vacuum develops, this valve opens to admit air, breaking the siphon without spraying water on personnel when the system starts up again.

Although that example comes from large industrial equipment, the principle transfers cleanly to smaller systems. Any RO installation where a drain line drops significantly below the RO unit and then runs for a distance can benefit from design features that allow air into the line when pressure falls. In homes, this role is often played by the air gap in an RO faucet, but dedicated anti-siphon valves and proper check-valve placement are also part of a robust design.

Health, Structural, And Regulatory Benefits

Anti-siphon features matter for three big reasons: protecting health, protecting equipment, and staying on the right side of plumbing codes.

First, health. Backflow and siphoning can carry contaminants from irrigation lines, soil, fertilizers, pesticides, or stagnant water into potable plumbing. Water-treatment articles make clear that such contamination can introduce disease-causing microorganisms and toxic chemicals into household water. Glossaries on anti-siphon devices highlight their role in preventing waterborne diseases by avoiding the backflow of polluted water. In industrial RO systems, the siphon-related failure mode described earlier does not just stress hardware; it also draws airborne bacteria and fungi into the vessels, potentially creating a biofilm that can seed downstream water with microbes.

Second, equipment life. Industrial case studies show that water hammer created when siphoned vessels suddenly refill can crack fiberglass wraps and damage internal anti-telescoping devices. While home RO units are smaller, the same combination of vacuum and sudden refilling is not kind to plastic housings, fittings, or storage tanks. Anti-siphon valves, vacuum breakers, and air gaps reduce the chance of those violent hydraulic events occurring in the first place by allowing air to enter and equalize pressure instead of letting a long column of water accelerate unchecked.

Third, regulatory compliance. Articles on anti-siphon valves emphasize that most plumbing and irrigation codes mandate some form of backflow protection at hose bibs, outdoor sprinklers, and many other cross-connections, and that failing to install required devices can lead to legal penalties. Irrigation resources note that homeowners in many jurisdictions are legally obligated to install backflow preventers at their water meters or main cross-connections. When you connect a point-of-use RO system to a municipal supply and drain, local inspectors may treat it as another such cross-connection. In my work walking homeowners through upgrades, I encourage them to align with local code not just to pass inspections, but because it reflects hard-earned experience about how to keep community drinking water safe.

Anti-siphon features are therefore not optional “extras” if you care about long-term health, stable operation, and compliance. They are part of the same layered protection philosophy that leads organizations such as the Water Quality Association to recommend combining RO membranes with carbon filters, and sometimes UV disinfection, rather than relying on a single treatment step.

Comparing Anti-Siphon Approaches In RO Systems

Different anti-siphon strategies offer different blends of protection, convenience, and complexity. The following table summarizes key points drawn from technical and plumbing resources.

Anti-siphon approach |

Where it appears in RO systems |

Main benefit |

Key trade-offs and considerations |

Air-gap RO faucet |

At the drinking-water faucet, usually above the sink |

Provides a true physical air gap between RO waste and household drain; helps satisfy plumbing codes for under-sink RO |

Can be noisier, uses more tubing, and may spill onto the countertop if small internal drain passages clog; installation can be more involved |

Non–air-gap faucet plus check valves |

At the faucet and on the waste line to the drain |

Quieter, simpler under the sink, and often easier to install on tight countertops |

Depends on check valves and proper plumbing rather than a physical air gap; some codes do not allow this configuration for RO systems |

Dedicated vacuum breaker or anti-siphon valve on drain or concentrate line |

On RO waste or concentrate piping, especially where lines drop to a lower drain |

Breaks siphons caused by vacuum conditions, preventing vessels or lines from being drained backward and reducing risk of water hammer |

More common in larger or custom systems; must be selected and installed correctly, and in many cases still works alongside an air gap or other backflow device |

For a typical homeowner choosing a new under-sink RO system, the decision often comes down to whether local codes require an air gap. If they do, an air-gap faucet is usually the most straightforward way to comply. If they do not, some people choose non–air-gap faucets for simpler installation and quieter operation, but should do so with their eyes open to the small added risk and the need for well-placed check valves and regular inspections.

Practical Advice For Homeowners And Renters

When I review an existing RO installation with someone, we start by tracing the water’s path. That same exercise can help you understand your own system and spot missing protections.

Look first at the faucet. If you can see three separate tubes attached under the countertop and two of them connect back to the RO system or the drain, you likely have an air-gap faucet. The product manual should confirm this and often includes a schematic that makes the air gap obvious. If you see only one line from the RO unit to the faucet and a single waste line from the RO module to a drain saddle on the sink plumbing, you probably have a non–air-gap configuration.

Next, find where the RO waste line connects to the household drain. It should typically tie in above the sink trap rather than below it, so that a blockage downstream in the drain stack does not trap contaminated water right at the connection point. Industrial guidance on RO systems makes clear that avoiding siphons from lower drains is crucial; while your home system is smaller, this is still a good principle to follow. If the waste line drops a long distance before entering a drain or passes through spaces where freezing or mechanical damage is possible, it is worth asking a qualified plumber or installer whether a vacuum breaker or anti-siphon valve is appropriate.

Backflow and anti-siphon devices need maintenance to keep working. Articles on anti-siphon valves recommend periodic inspection for leaks or damage and seasonal preparation to avoid freeze damage, especially in plastic-bodied valves. Irrigation resources suggest having backflow prevention assemblies inspected once or twice a year by a qualified professional. For RO systems, a practical approach is to incorporate a visual check of the faucet, drain saddle, and any visible valves whenever you replace filters or sanitize the system. If you ever notice unusual gurgling, water spilling from an air-gap faucet, or slow draining from the RO waste line, treat that as a signal to investigate rather than ignoring it.

If you are renting or cannot modify your plumbing easily, countertop RO systems can be attractive because they usually connect to a faucet or sit independently with a separate purified-water carafe. Articles on modern countertop RO units describe them as plug-and-play, requiring no permanent installation and often using glass containers for pure water storage. While these systems still produce a waste stream that must be handled responsibly, they reduce the number of permanent plumbing cross-connections, which can simplify backflow compliance. Even so, you should follow the manufacturer’s guidance on how and where to discharge any waste water.

Finally, when you shop for a new RO system, consider both water treatment and water efficiency. EPA’s WaterSense program points out that many point-of-use RO units waste several gallons of reject water for every gallon of treated water. WaterSense-labeled RO systems are required to send no more than about 2.3 gallons of water down the drain per gallon of purified water produced, while still maintaining contaminant removal performance. Choosing a system that both protects against backflow and uses water efficiently gives you cleaner water without unnecessary waste.

FAQ: Anti-Siphon Features And Your RO System

Do I really need an anti-siphon feature if my RO system already has good filters?

Filtration and anti-siphon protection solve different problems. The RO membrane and pre-filters are there to remove contaminants moving forward with the flow of water. Anti-siphon devices act when something goes wrong in the plumbing system and water tries to move backward. Technical resources on water treatment emphasize multi-barrier protection: first keep contaminants out of your water as much as possible, then remove what gets through. Anti-siphon features belong in that first category. Without them, an event like a severe drain backup or sudden supply pressure drop can expose your RO system, and by extension your drinking water, to contamination that no one intended.

Will an air-gap faucet or anti-siphon valve change the taste or mineral content of my water?

Anti-siphon devices do not add chemicals or change the composition of water that has already been treated. Their job is to control direction of flow and admit air when necessary, not to filter or alter the water itself. Taste and mineral content in an RO system are governed mainly by the membrane and any remineralization cartridges downstream. Articles on RO and mineral content explain that RO membranes remove both harmful substances and beneficial minerals, and that many modern systems add minerals back later for taste and pH balance. Anti-siphon features make sure nothing contaminated travels backward into that treated water; they do not affect flavor directly.

How often should I have my RO system’s anti-siphon and backflow protections checked?

Irrigation and plumbing resources recommend that backflow prevention devices in general be inspected once or twice a year by qualified professionals. While residential RO systems are smaller and often simpler, it is sensible to align anti-siphon checks with your normal maintenance schedule. Whenever you replace filters, sanitize the system, or have a plumber in for other work, take the opportunity to confirm that the RO faucet type matches local code, that drain connections are intact and correctly positioned, and that any visible anti-siphon or check valves are not leaking or damaged. Catching a failing device early is far easier than dealing with contamination or water damage later.

In the end, a reverse osmosis system without robust anti-siphon protection is a bit like a well-stocked first-aid kit sitting behind an unlocked, unmarked door. The tools are valuable, but their usefulness depends on basic safeguards. When you pair proven RO filtration with thoughtfully designed anti-siphon features, you get what you really want at the tap: water that is not only clean on paper, but better protected against the surprises that real-world plumbing can throw at it.

References

- https://www.epa.gov/watersense/point-use-reverse-osmosis-systems

- https://healingwaters.org/water-treatment-in-developping-countries/

- https://wqa.org/resources/reverse-osmosis-ro/

- https://www.kreo.net/glossary/anti-siphon

- https://www.brotherfiltration.com/the-impact-of-reverse-osmosis-on-global-water-systems/

- https://www.chunkerowaterplant.com/news/main-problems-with-ro-systems

- https://www.dripworks.com/blog/what-is-irrigation-backflow-and-how-do-backflow-valves-prevent-it?srsltid=AfmBOoo8kEUGtrnjIH6w0Ey5wgsYud9Snf1SqFC4L_Mv3HvR8UjCTznj

- https://espwaterproducts.com/pages/air-gap-vs-non-air-gap-faucets-for-reverse-osmosis?srsltid=AfmBOooE8f3WH5xXpZtwPv6Mkjuz41pDPxPvJ7iITHADXBZRiSem16wN

- https://ethanolproducer.com/articles/common-mistakes-in-design-use-of-reverse-osmosis-systems-5833

- https://hawaiiancoolwater.com/the-truth-behind-reverse-osmosis-water-systems-filtering-out-fact-vs-fiction/

Share:

Impact of Membrane Fiber Density on RO Performance Analysis

95% vs 98% RO Membrane Desalination: How Much Difference Does It Really Make?