As a smart hydration specialist, I am often called in when a “perfectly good” reverse osmosis system suddenly starts producing a weak trickle or flat‑tasting water. The owner has already changed filters, checked for leaks, and scrubbed the faucet. In more cases than you might expect, the real culprit turns out to be invisible: incorrect or unstable voltage feeding the RO pump and electronics.

Voltage is not as glamorous as membrane technology or remineralization stages, but it is just as critical to the health of your RO system and the quality of the water you drink. In this guide, we will walk through how voltage drives pressure, which voltages different RO systems actually need, what can go wrong electrically, and how to choose and maintain the right power supply for reliable, great‑tasting water.

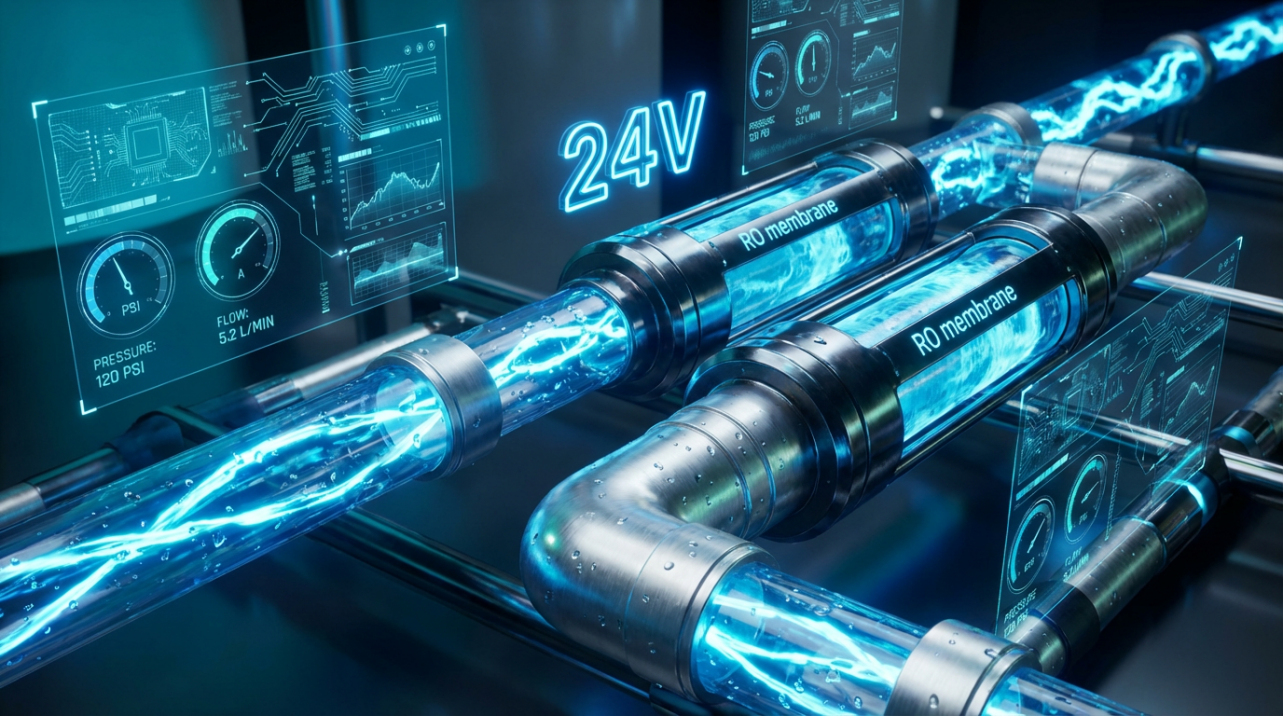

How Reverse Osmosis Uses Electricity to Make Pressure

Reverse osmosis is a pressure‑driven process. The system forces water through a semi‑permeable membrane that blocks most dissolved salts, organics, and particles while letting water molecules pass. To overcome natural osmotic pressure, especially in mineral‑rich or salty water, the pump must raise pressure significantly inside the membrane housing.

Industrial research summarized by Aqualitek shows that the high‑pressure pump typically consumes about 70–90% of an RO plant’s electricity, and electricity itself can account for roughly 30–60% of total operating cost. That is for large installations, but the principle is the same in your under‑sink unit: most of the power is spent on turning electrical energy into hydraulic pressure.

Voltage is the “electrical pressure” that pushes current through the motor windings of the pump. The pump is engineered to deliver a target pressure and flow at a particular voltage and current. When the voltage is too low, the motor cannot draw enough power to reach the designed pressure. You see that as slow production, a storage tank that never quite fills, or sometimes a system that does not start at all. When voltage is too high or wildly unstable, the motor and electronics run hot, protection circuits trip, and components wear out prematurely.

In other words, for RO systems, voltage is not just a number on a label. It is directly tied to the pressure that drives filtration and, ultimately, the water you drink.

Typical Voltage Levels in RO Systems

To understand voltage requirements, it helps to separate the input that comes from the wall, battery, or solar array from the low‑voltage supply that actually runs the pump and control board.

Most residential RO systems in the United States plug into a standard 110–120 volt AC outlet, as described in guidance from WATERLUX. Inside the unit or in an external “brick,” that mains voltage is converted down to low‑voltage DC. That DC rail powers the booster pump, valves, and control electronics.

The exact low voltage depends on system size and design.

Home under‑sink and countertop systems

In typical domestic systems, a dedicated power adapter or SMPS (switched‑mode power supply) converts 110–120 volt AC (or 100–275 volt AC in globally rated adapters) down to 24 or sometimes 36 volt DC. Several sources converge on this:

A 24 volt, 1.5 amp transformer is marketed specifically for 75 gallon‑per‑day booster pumps. This pairing is described as “perfectly matched” for stable pressure and pump life.

A 24 volt, 4 amp (96 watt) adapter is designed to drive 24 volt DC pumps in the 200–400 gallon‑per‑day range, with wide input tolerance from about 100 to 275 volt AC and protective features against over‑voltage, over‑current, overheating, and short circuits.

RO service specialists report that most modern domestic systems use 24 volt supplies around 2.5–3 amp, or 36 volt 3 amp supplies for slightly heavier loads, to power both the booster pump and accessories such as UV lamps and sensors.

In my field work looking at home hydration upgrades, I see this pattern over and over: a 24 volt DC output in the range of 1.5 to about 4 amp feeding a booster pump sized to the membrane’s gallon‑per‑day rating. The higher current adapters support higher‑capacity membranes and higher production rates.

Modern SMPS units, described by providers such as RomegaMart, RO Service Point, and GVE, are compact, relatively cool running, and efficient.

RO‑grade SMPS supplies typically reach about 85–90% efficiency, compared with roughly 60–70% for older transformer‑based supplies, and often last three to five years in normal domestic service when protected from moisture and extreme heat. They also integrate important protections that shut the unit down during surges, shorts, or severe over‑temperature events instead of sacrificing the pump or control board.

Commercial and industrial plants

Commercial and industrial RO plants are more diverse electrically. Many still use low‑voltage SMPS units for controls, sensors, and small pumps, but the main high‑pressure pumps are often driven directly by standard AC motors.

RO Service Point notes that:

Domestic plants around 25–100 liters per hour typically use 24 volt 2.5–3 amp or 36 volt 3 amp SMPS units.

Commercial plants step up to around 24 volt 5 amp or 36 volt 3–5 amp, reflecting multiple pumps and heavier duty cycles.

Industrial plants often run 48 volt SMPS at 5–15 amp or higher to feed multiple high‑pressure pumps and PLC automation panels.

At even larger scales, solar and hybrid developers such as Elemental Water Makers describe using 230 volt single‑phase or 380 volt three‑phase AC for pumps once power demand passes about 15 kilowatts or daily production exceeds roughly 50,000 liters, which is on the order of 13,000 gallons per day.

The takeaway for a building or facility owner is that once you move beyond point‑of‑use devices, the installation will almost always combine several voltage levels: a mains‑level AC supply for high‑power pumps and one or more low‑voltage DC rails for controls and auxiliary equipment. Matching each load to the correct voltage is essential for safety and reliability.

Solar and hybrid RO systems

Solar‑driven RO systems introduce another layer, because the raw power source is often a low‑voltage DC array. Elemental Water Makers reports that:

Direct‑DC systems commonly use 24 volt DC for smaller plants producing up to about 10,000 liters per day, which is roughly 2,600 gallons per day.

Larger DC plants, producing around 10,000–50,000 liters per day, or roughly 2,600–13,200 gallons per day, often shift to 48 volt DC to keep current manageable and reduce cable size.

Above that scale or power levels beyond about 15 kilowatts, designers typically convert to 380 volt three‑phase AC for the high‑pressure pump, often via inverters in a hybrid solar‑grid setup.

Raising system voltage in these plants is not about making the water taste better. It is about making power delivery efficient and safe. For instance, Elemental Water Makers gives a 5 kilowatt load example: at 24 volt DC, that load would draw around 208 amp; at 48 volt DC, the same power needs roughly 104 amp. Over a 50 foot run, that difference can translate into cable cross‑sections roughly three times smaller and meaningful savings in copper and installation cost, while also reducing voltage drop that would otherwise starve the pump.

How Voltage Affects Pressure, Flow, and Water Quality

Because RO is pressure‑driven, anything that affects pump performance shows up quickly as “water issues.” SimPure and WATERLUX both highlight that most residential RO systems are designed to operate within a pressure window of about 0.2–0.5 megapascals at the membrane, which corresponds to roughly 29–72.5 psi. Below about 0.18 megapascals, around 26 psi, salt removal efficiency drops dramatically; above 0.5 megapascals, joints and multi‑port valves are stressed and leaks or mis‑operation become more likely.

The booster pump needs stable, adequate voltage to reach and sustain that pressure range. Here is how that plays out in practice.

Low voltage and low pressure

When the voltage feeding the pump falls below its design point, the pump draws less power. It may still run, but not fast or strong enough to build the required pressure.

SimPure describes several symptoms of this situation:

The RO system may not start at all, or it may start and then shut itself off quickly.

Water from the faucet may slow to a weak trickle, or the storage tank never seems to fill fully.

Salt absorption and regeneration processes tied into the system perform poorly, leaving product water with higher dissolved solids.

In my own inspections, I often see this after someone has replaced a failed adapter with a visually similar but lower‑voltage unit. For example, a pump that requires 24 volt DC is accidentally fed with a 12 volt DC adapter because the plug fits. The pump hums and tries but cannot reach design pressure. The owner hears more noise and sees less water, and often blames the membrane.

WATERLUX notes that unstable supply voltage at the wall can have the same effect. Sagging mains voltage leads to inconsistent pump performance, intermittent operation, and even unexplained shutdowns. Especially in areas with frequent brownouts or wide swings on the grid, a stabilizer or surge‑protected circuit can make the difference between a quiet, dependable RO and a chronic headache.

Surges, spikes, and high voltage

On the other side, RO electronics and pumps are not happy when voltage spikes above intended limits. High‑quality SMPS units from vendors such as Axtron, GVE, and RomegaMart include protection against over‑voltage, over‑current, overheating, and short circuits precisely because power in real homes is rarely perfect.

WATERLUX details the cascade of issues that follow from serious electrical faults:

Tripped breakers from overloads, short circuits, or ground faults that cut power altogether.

Pump startup failures after surges damage motor windings or the transformer that feeds the pump.

Dead or erratic control panels when control boards, touchpads, or wiring suffer from repeated transients.

Bad wiring connections and corroded terminals that create hot spots, buzzing noises, or intermittent operation.

In practical terms, that is why most manufacturers strongly recommend proper grounding, use of a dedicated circuit, and surge protection for RO systems.

A seventy‑five psi pressure on the membrane is perfectly safe. A stray surge on a poorly protected line is not.

Internal operating pressure versus line pressure

One point that can confuse homeowners is the difference between pressure at the membrane and the pressure of the municipal supply. SimPure notes that for typical freshwater sources such as tap water, river water, groundwater, or reservoir water, RO membranes themselves often operate at internal pressures around 8–12 bar, which is roughly 115–175 psi. Seawater membranes can require around 45 bar, about 650 psi. These are internal pressures inside the housing driven by the high‑pressure pump, not the pressure at your faucet.

Line pressure in a house that feeds an under‑sink RO system is usually much lower, often in the range of 30–80 psi, and domestic guidance such as the RODI controller discussion suggests that around 75 psi is a reasonable upper operating point for household RO systems to avoid membrane damage. That is why a booster pump and the correct voltage supply are so important: they “step up” modest supply pressure into the higher pressure region that the membrane needs, in a controlled and safe way.

Selecting and Upgrading Your RO Power Supply

When clients ask about upgrading or replacing RO components, I always start with a simple habit: read the label. The little rectangle on the power adapter or SMPS casing tells you almost everything you need to know about voltage requirements.

A properly labeled adapter will list its AC input range, for example 100–275 volt AC at 50–60 Hz, and its DC output, such as 24 volt DC at 4 amp. From the perspective of your RO system, that DC output is what matters.

RO Service Point and GVE highlight several practical rules that are worth following carefully.

Always match voltage exactly. If the original supply says 24 volt DC, the replacement must also be 24 volt DC. Feeding a 24 volt pump with 36 volt DC risks immediate overheating and failure. Feeding it with 12 volt DC will make the pump struggle, run noisily, and fail to produce proper pressure.

Size current with a margin. The adapter’s amp rating, for instance 1.5 amp for a 75 gallon‑per‑day pump or 4 amp for a 200–400 gallon‑per‑day pump, should meet or slightly exceed the pump’s requirements. Undersized supplies run hot and may trip or fail prematurely. Oversized supplies are generally safe as long as the voltage matches, because the pump only draws what it needs.

Prefer RO‑grade SMPS units. RO Service Point notes that RO‑specific SMPS supplies are designed for damp environments, frequent cycling, and inductive loads such as pumps. They typically offer about 85–90% efficiency, lower heat, and three to five year lifespans, compared with about 60–70% efficiency and two to three years for older transformer‑based units.

Consider waterproofing and certifications. GVE emphasizes that around water, power supplies should have appropriate ingress protection ratings, robust housings, and compliance certifications, such as UL or similar, to reduce electrical hazard risk.

If you are unsure, taking a clear photo of the existing adapter label and sharing it with your installer or supplier is often the safest path.

They can cross‑match the exact voltage and current and recommend an appropriate replacement that includes modern protective features.

When 24 Volts, 36 Volts, or 48 Volts Make Sense

Within low‑voltage RO power supplies, the most common designations you will see are 24 volt, 36 volt, and 48 volt. Each has a natural home.

In domestic under‑sink systems, 24 volt DC is by far the most common. Twenty‑four volt supplies in the 1.5–4 amp range cover everything from 75 gallon‑per‑day booster pumps up through 200–400 gallon‑per‑day tankless systems, such as the 600 gallon‑per‑day tankless RO unit installed in one Alliance RV case. That installation used a 12 to 24 volt boost converter rated at about 10 amp, roughly 240 watts, so the RO system could run directly from the RV’s 12 volt battery instead of requiring shore power AC.

Thirty‑six volt DC supplies show up more often in commercial RO plants and some premium residential systems that incorporate larger pumps, more extensive UV treatment, or higher flow rates. RO Service Point notes 36 volt, 3–5 amp ratings as common for commercial configurations.

Forty‑eight volt DC and higher are associated mostly with industrial plants and larger solar‑powered systems. At those voltages, system designers can deliver the same power at lower current, reducing resistive losses and cable size. For example, Elemental Water Makers’ solar guidance shows that doubling voltage from 24 to 48 volt cuts current for a given power load roughly in half, which can reduce cable cross‑section significantly over long runs.

In off‑grid and battery‑based systems, the same logic applies. Samlex America’s analysis of 24 volt inverters points out that 24 volt architectures are more efficient and scalable than 12 volt setups for heavier or continuous loads. For the same power, current is roughly halved at 24 volts compared with 12 volts, which lowers voltage drop, allows thinner cables, and can cut wiring cost substantially. For an RV or cabin where an RO system is one of several continuous loads, building the power system around 24 volts can be a smart, future‑ready strategy.

Voltage Requirements Across Common RO Scenarios

To bring these ideas together, it helps to visualize how voltage and scale line up in real‑world systems.

RO scenario |

Typical water production |

Typical electrical supply |

Notes |

Under‑sink home RO with 75 GPD pump |

Around 75 gallons per day |

110–120 volt AC input, 24 volt DC, about 1.5 amp output |

Transformer or SMPS matched to a 75 GPD booster pump for consistent household use. |

High‑capacity domestic RO, 200–400 GPD |

Around 200–400 gallons per day |

110–120 volt AC input, 24 volt DC, about 4 amp (≈96 watts) |

Higher‑current 24 volt adapters support stronger pumps and on‑demand, tankless designs. |

Commercial RO plant |

Dozens to hundreds of gallons per hour |

220 volt AC motors plus 24 or 36 volt DC at 3–5 amp for controls |

Larger high‑pressure pumps on AC; SMPS feeds controls, UV, and smaller pumps. |

Small solar‑driven RO |

Up to ~10,000 liters per day (≈2,600 gal/day) |

24 volt DC array or battery bus |

Direct‑DC pumps or inverters sized to handle daytime production and storage. |

Medium solar or resort RO |

~10,000–50,000 liters per day (≈2,600–13,200 gal/day) |

48 volt DC, often with hybrid 230/380 volt AC |

Higher voltage reduces current and wire size; AC used for main pump in hybrids. |

Large industrial or municipal RO |

Above ~50,000 liters per day |

380 volt three‑phase AC plus 24/48 volt DC for controls |

Complex systems with dedicated MCCs, VFDs, and separate low‑voltage control networks. |

The key pattern is that the higher the total power required to push water through membranes, the higher the system voltage tends to be, either on the DC or AC side. At the same time, the low‑voltage rails that run electronics and small pumps remain in the 24–48 volt range, even in very large plants.

Protecting Your RO System from Electrical Problems

From a homeowner’s perspective, most electrical problems in RO systems show up first as water symptoms: low flow, strange noises, or erratic operation. The WATERLUX overview of common issues provides a useful map of how these symptoms connect back to voltage.

Unstable line voltage causes inconsistent pump behavior, low water pressure, and occasional shutdowns. Using a surge protector or voltage stabilizer and ensuring proper grounding helps smooth those fluctuations.

Complete power loss usually traces back to loose connections, faulty transformers, tripped overload switches, or damaged wiring. You may notice humming or buzzing before a failure, as described by suppliers such as AXEON, when stressed components struggle under electrical or mechanical strain.

Repeated breaker trips point to overloads, short circuits, or ground faults. Electrical professionals highlight that circuit breakers are the guardians of the system, tripping deliberately to prevent fire and serious damage. If a breaker will not stay reset, that is a clear signal to call an electrician, not a reason to bypass protection.

Pump startup failures can be caused by voltage surges, motor faults, or weak transformers. Diagnostic steps typically include measuring line and transformer voltage with a multimeter, evaluating the transformer for overload, and testing the pressure switch and motor separately. For residential users, these are tasks for a trained technician rather than a DIY project.

Bad wiring connections or corroded terminals produce humming, flickering lights on control panels, intermittent operation, and sometimes discoloration or heat at connection points. Regular inspections by a professional, use of anti‑corrosion treatments, and ensuring the system is on a properly rated dedicated circuit can prevent many of these issues.

The thread that connects all of this is simple: water and electricity are a risky combination. Reputable guidance from GVE and WATERLUX is consistent on this point. Homeowners can and should monitor symptoms, keep power supplies dry and ventilated, and use surge‑protected, grounded outlets. But repairs inside the RO’s electrical circuit, including wiring changes or control board replacements, should be handled by a licensed electrician or a qualified RO technician.

Monitoring Performance: Voltage, TDS, and More

Voltage is not a household metric you can taste, but its effects reach all the way to the glass. That is why I encourage homeowners to pair basic electrical awareness with simple water‑quality monitoring.

TDS and conductivity as a quick check

Reverse osmosis sharply reduces the ionic content of water, which lowers its electrical conductivity. Conductivity is measured in microsiemens per centimeter and is closely related to total dissolved solids, usually expressed in parts per million.

Technical guidance compiled by water‑quality specialists shows that municipal tap water often ranges from about 100–800 microsiemens per centimeter, which corresponds roughly to 50–500 or more parts per million of dissolved solids. Properly functioning household RO product water is typically in the range of about 1–50 microsiemens per centimeter, equating to only a few parts per million.

Simple “TDS meters” sold for home use are actually conductivity meters with a fixed conversion factor. They are not laboratory‑grade instruments, and they do not detect every kind of contaminant, but they are useful for trend monitoring. A healthy RO usually maintains a stable ratio between feed and product TDS, often achieving 90–99% ion rejection.

In the Alliance RV installation mentioned earlier, the tankless RO’s smart faucet includes a digital TDS display and filter status indicator, so the owner can see in real time how well the system is removing dissolved solids. This kind of feedback is especially valuable when you have made electrical changes, such as switching to a new adapter or adding a DC‑DC converter. If product TDS suddenly rises after an electrical change, it is a sign to verify both the new power supply and the membrane.

One useful rule of thumb from a RODI controller discussion is that TDS around 10 parts per million is considered “a bit low” for everyday drinking, while 20–40 parts per million is a commonly accepted range for pleasant‑tasting water. Many systems use remineralization filters downstream of RO, like the WaterDrop setup in the RV example, to bring TDS and alkalinity back into that range for taste and stability while keeping contaminant levels low.

Preventive maintenance that protects both membranes and power supplies

Proper voltage and clean water pathways reinforce each other. RO Service Point notes that overloaded, jammed, or failing pumps can draw excess current and overload the SMPS, especially when filters are clogged and pressure rises. Conversely, a weak or failing power supply can underfeed the pump, leading to low pressure and poor filtration that accelerate membrane fouling.

Manufacturers and service providers offer several consistent maintenance suggestions:

Keep the power supply dry and dust‑free. Wipe the housing periodically, ensure vents are not blocked, and avoid placing it where leaks could drip directly onto it.

Use a stabilizer or surge protector in regions with unstable mains electricity. This reduces stress on both the SMPS and downstream electronics.

Replace defective pumps promptly. A pump that is stalled or drawing too much current can overheat the power supply and shorten its life.

Change pre‑filters and sediment filters on schedule. Clean filters reduce the pressure drop the pump must overcome, which lowers energy use and mechanical stress.

Inspect wiring and connectors occasionally for signs of corrosion, discoloration, or heat. Address problems early before they become safety hazards.

These are not glamorous tasks, but they are the kind of low‑effort habits that keep both the water side and the electrical side of your RO system in a healthy balance.

Frequently Asked Questions About RO Voltage

What voltage do most home RO systems use?

Most household RO systems in the United States plug into 110–120 volt AC wall outlets. Internally, however, the majority of modern under‑sink and countertop units convert that to 24 volt DC to power the booster pump and electronics. RO service data shows common ratings around 24 volt DC at 2.5–3 amp for domestic plants, with specific pairings such as 24 volt 1.5 amp for 75 gallon‑per‑day pumps and 24 volt 4 amp for 200–400 gallon‑per‑day, higher‑capacity pumps. Some systems and small commercial units step up to 36 volt DC at around 3 amp or higher.

When replacing an adapter, you should match that low‑voltage DC rating exactly. The written voltage and polarity on the output label matter more to the RO pump than the input from the wall.

Can I run a 24 volt RO pump on a 12 volt battery system?

Not directly. A 24 volt pump requires about 24 volt at its terminals to perform correctly. Feeding it with 12 volt DC, even if the plug fits, will leave it underpowered and unable to build the proper pressure. That results in slow production, poor filtration, and premature wear.

There are safe ways to integrate a 24 volt RO into a 12 volt system. The Alliance RV owner with a WaterDrop 600 gallon‑per‑day tankless RO used a DC boost converter that steps 12 volt DC from the RV battery up to 24 volt DC at around 10 amp, roughly 240 watts. This allowed the tankless system to run fully from the RV’s DC system, without relying on shore power AC, while still giving the pump the voltage it was designed for.

If you plan something similar for an off‑grid cabin or RV, it is important to choose a high‑quality DC‑DC converter that is rated for inductive loads such as pumps. Forum discussions on DC converters emphasize that not all converters handle motors well. Many designers, including Samlex America, recommend building serious off‑grid systems around 24 volt battery banks and inverters when continuous loads like RO pumps are involved, because higher system voltage reduces current, cabling cost, and voltage drop.

Do I really need a surge protector or voltage stabilizer for my RO?

Strictly speaking, an RO system will run without dedicated surge protection as long as the grid remains clean and voltage stays near nominal. In practice, however, very few real‑world electrical systems are that well behaved.

WATERLUX points out that voltage fluctuations show up quickly in RO systems as reduced pressure, intermittent pump operation, and occasional shutdowns. Power losses from loose connections, tripped breakers, and faulty transformers are also common. GVE stresses that power supplies for water purifiers operate in wet, often cramped environments where the consequences of an electrical fault are more serious than for many other appliances.

Using a surge protector or voltage stabilizer for your RO system, ideally on a dedicated circuit with proper grounding, is therefore a sensible preventive step. It helps protect the SMPS, pump, and control electronics from the most damaging spikes and sags, extends the lifespan of the equipment, and makes water quality more consistent. Given the relatively modest cost of a good surge protector compared with a high‑quality RO system, this is one of the simplest insurance policies you can buy for your home hydration.

Reliable hydration at home depends on more than membranes and filter cartridges. The quiet power supply tucked under your sink or behind a panel is the unsung heart of the system, turning household voltage into the precise electrical “pressure” your pump needs to create clean, low‑TDS water. When you understand your RO system’s voltage requirements, you are far better equipped to choose the right equipment, spot early warning signs, and work with professionals to keep both the electrical and water sides healthy. That is how you move from “it works most of the time” to a truly dependable, science‑backed hydration setup for your home.

References

- https://www.energy.gov/femp/articles/reverse-osmosis-optimization

- https://bdigital.zamorano.edu/bitstreams/ad658665-f77c-46a5-a8d8-c12b6127a086/download

- https://www.aqualitek.com/best-guide-where-does-the-majority-of-an-ro-system-s-power-consumption-come-from-insights-by-aqualitek.html

- https://www.gapswater.co.uk/products/transformer-24v-1-5a-for-use-with-75-gpd-booster-pump?srsltid=AfmBOorBI9u7UNJv4f7sV2azZroW-BsYOuc9LqlQ6mGfGj8-4bqA7KCm

- https://www.gve-cn.com/article/water-purifier-power-supply-everything-you-need-to-know.html

- https://samlexamerica.com/why-24v-power-inverters-are-the-smarter-choice-for-off-grid-systems/

- https://sprinter-source.com/forums/index.php?threads/73561/

- https://forum.arduino.cc/t/rodi-controller/391957

- https://atlas-scientific.com/blog/reverse-osmosis-water-conductivity/?srsltid=AfmBOoqPcX5ZBKX-Pz_SqMOigw8MT08P0ohzQKgKGRCcE6G0X6H3MCmG

- https://axtronpakistan.com/product/24v-4a-domestic-ro-plant-power-adapter-for-water-filter-systems-high-performance-power-supply-in-pakistan/

Share:

How Capacitive Touch Control in Smart Faucets Achieves Water Resistance

Understanding the Effectiveness of 253.7 nm Wavelength UV Lamps