Why Sudden Pump Noise Matters For Home Hydration

If you rely on a pressure pump to feed a whole-house filter, a UV system, an under-sink reverse-osmosis unit, or a private well, that pump is the quiet heart of your home hydration system. Under normal conditions, most modern pumps produce a steady, even hum that fades into the background. Data from manufacturers like Becker Pumps and Pumptec show that many small pumps sit in the range of a household vacuum or hair dryer at about three feet away, yet still allow normal conversation in the room.

When that familiar sound suddenly changes into a roar, rattle, screech, or sharp banging, your pump is telling you something important. Across many technical sources, from Allied Pumps and Enviro Waste to Pumptec and Winston Engineering, one theme is consistent: unusual or louder noise is not “just annoying.” It is an early warning sign of hydraulic, mechanical, or electrical stress that can lead to:

- Premature pump failure and expensive replacement.

- Leaks or bursts that threaten nearby equipment and structures.

- Interruptions to clean water supply, affecting drinking, cooking, and hygiene.

As a smart hydration specialist, I tell homeowners to treat sudden noise like a smoke alarm for their water system. If you respond early, you can often fix a small issue, protect your filtration equipment, and keep your water safe and reliable.

What “Normal” Sounds Like – And What Does Not

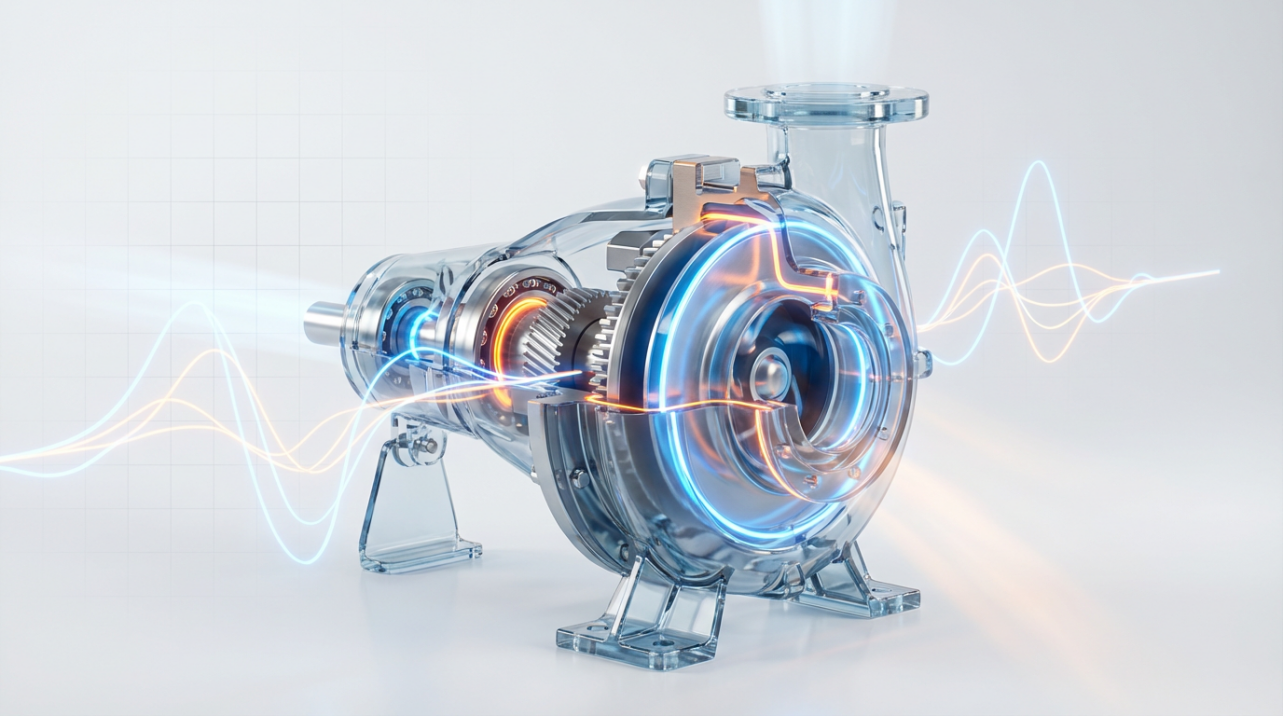

Most pressure pumps in home systems are either centrifugal or positive-displacement designs (such as plunger or diaphragm pumps, or compact booster pumps). When correctly sized, properly primed, and well maintained, they typically:

- Start with a brief ramp-up sound as they come up to speed.

- Settle into a smooth, consistent hum with minor vibration.

- Change sound slightly as faucets open and close, but without sharp, metallic, or crackling noises.

Manufacturers like Pumptec and Winston Engineering note that higher-flow plunger pumps are naturally louder than small centrifugal pumps, and gas-driven units naturally out-noise electric models. But what matters most in a home is change: a sudden step up in loudness, a new harsh tone, or vibration you can feel through nearby walls and floors.

A dramatic change in sound over hours or days is therefore more important than the absolute decibel reading. If your pump suddenly sounds like gravel rattling in a metal can, metal grinding on metal, or pipes banging in the walls, you are likely dealing with one of three broad categories of problems:

- Hydraulic issues in the water itself, such as cavitation, air entrapment, or water hammer.

- Mechanical problems, such as worn bearings, loose hardware, misaligned or damaged impellers, or poor mounting.

- Electrical or control faults that make the motor struggle, hum, or vibrate abnormally.

The rest of this article walks through each category, using field-proven guidance from Allied Pumps, Enviro Waste, Hydparts, Envirowaste, Epp Well Solutions, Pumptec, and others, and then shows how to triage the situation in a home hydration system.

Noise Patterns And What They Often Mean

While sound alone cannot give a perfect diagnosis, consistent patterns show up repeatedly across industrial and residential pump literature. Enviro Waste, Hydparts, Streampumps, and Pump Repair Services in Florida all highlight the value of “listening carefully” as a first diagnostic step.

The table below summarizes common noise patterns and their most likely categories, with examples drawn from these sources.

Noise pattern and behavior |

Likely category |

Typical root causes (from multiple sources) |

Immediate risk level in a home system |

Sudden rattling or “rocks in a can” under load |

Hydraulic (cavitation) |

Restricted inlet, low suction head, clogged strainers, high pump speed, over-pumping |

High: can erode impellers and quickly damage pump |

Gurgling, slurping, or airy hissing with flow surging |

Air entrainment or aeration |

Suction-side air leaks, poor priming, trapped air in lines or filters |

Moderate to high: can cause wear and loss of prime |

Single or repeated loud bangs in pipes |

Water hammer |

Valves closing quickly, excessive pressure, undersized expansion or pressure tank |

High: pipe and fitting damage, risk to fixtures |

High-pitched squeal or screech, often increasing slowly |

Mechanical (bearings/belts) |

Dry or contaminated bearings, misaligned pulleys, loose or worn belts |

High over weeks: bearing failure, seized motor |

Deep grinding or growling, strong vibration |

Severe mechanical wear |

Advanced bearing wear, debris in impeller, impeller rubbing casing |

High: stop and inspect; risk of catastrophic failure |

Constant loud hum, pump not building pressure |

Electrical or motor issue |

Low voltage, bad capacitor or relay, stalled impeller, wiring fault |

High: risk of motor burnout or overheating |

Rhythmic knocking in sync with strokes or speed |

Alignment or structural |

Loose mounting bolts, misaligned coupling, resonance in piping or base |

Moderate: damage grows if run for long |

In practice, you may hear a combination.

For example, cavitation can start as a crackling noise, then progress to broadband roar plus vibration as impeller damage and bearings begin to suffer, which matches descriptions from Allied Pumps, Hydparts, and audio-based research on cavitation in centrifugal pumps.

Hydraulic Causes: Cavitation, Air, And Water Hammer

Cavitation – When Your Pump Starts “Eating” The Water

Cavitation is one of the most common hydraulic causes of sudden loud noise. Allied Pumps, Pumpworks, Hydparts, Winston Engineering, and several academic studies all describe cavitation in similar terms: vapor bubbles forming in low-pressure regions of the pump, then imploding violently as they move into higher-pressure zones.

When local pressure drops below the water’s vapor pressure at the pump inlet or within the impeller passages, pockets of vapor form. As these pockets travel into higher-pressure regions, they collapse with shock-like micro-impacts that:

- Sound like gravel, marbles, or crackling inside the pump body.

- Increase vibration, especially in the mid- to high-audio range.

- Chip away at impeller blades and casing, reducing efficiency.

Allied Pumps notes that this “rocks in a can” sound often tracks with abnormal suction and discharge gauge readings. Hydparts and Pumpworks add that cavitation typically appears when Net Positive Suction Head available is too low, due to long or undersized suction piping, clogged strainers, high pump speed, or excessive suction lift. Vertisys points out that for many circulating systems, the required suction head to avoid cavitation is often on the order of a few feet of water column.

In a home hydration context, cavitation shows up when a well or booster pump is starved of water by the system that feeds it. Common scenarios include:

- A sediment prefilter that has quietly clogged, starving the pump.

- A partially closed isolation valve on the suction side.

- A well with limited yield where family demand exceeds recharge, as described by Epp Well Solutions in low-yield wells producing under about one gallon per minute.

- A booster pump set to a much higher speed or pressure than the upstream source can support.

Imagine an under-sink booster for a reverse-osmosis system drawing from a rainwater tank. If the tank is low and a small leaf or slug of debris partially blocks the suction line, you may hear a sudden rattle as cavitation starts whenever someone fills a pitcher. If ignored, the impeller edges can become pitted and rough over months, making the pump permanently louder and less efficient.

From a health perspective, cavitation-induced damage matters because it shortens pump life, increases the chance of particles or metal flakes in the water path, and may suddenly disable the system, leaving you without filtration when you need it most.

Air Entrapment And Aeration – When Bubbles Join The Party

Air in the system is another frequent cause of new, odd noises. Envirowaste, Enviro Waste, Pump Repair Services, Hydparts, and Streampumps all describe variations of this problem:

- Trapped air pockets in the pump body or piping cause gurgling and surging.

- Air leaks on the suction side let small bubbles into the line, leading to a rumbling or airy hiss.

- Mixed air and water at the discharge reduce flow and cause erratic pressure.

The sound profile can range from “hissing” and “slurping” to irregular bubbling, especially when faucets open and close. Hydparts uses the term aeration when air enters through loose couplings or leaking seals, and notes that it increases wear and can damage seals and internal surfaces.

In residential pressure-pump systems, typical causes include:

- Loose or cracked suction fittings on a booster pump.

- A poorly sealed well suction line or leaking foot valve.

- Improper priming after maintenance work on filters or softeners.

- An automatic air-release valve that has failed or was never installed in a location prone to air accumulation.

Troubleshooting guidance from Pump Repair Services and Envirowaste emphasizes three practical steps for homeowners:

First, visually inspect and tighten suction-side fittings, paying attention to any dampness, rust stains, or whitish mineral tracks that suggest micro-leaks.

Second, bleed the system where possible, using dedicated air-release valves or by carefully opening high-point taps until air spurts and then runs clear with steady pressure.

Third, confirm that the pump is properly primed and that the suction intake is submerged adequately below the water surface, as Streampumps and Allied recommend, so the pump is not intermittently sucking air.

If noise and flow stabilize after removing air, you have likely prevented further cavitation-like damage and restored smoother operation.

Water Hammer – The Sudden Bang In Your Walls

While cavitation and aeration usually create continuous or crackling sounds, water hammer announces itself as a distinct, often alarming bang or series of bangs. Pumptec, Winston Engineering, and Callaghan Pump describe water hammer as the implosion of a large air pocket or the shock of a rapid flow stop when a valve or faucet closes quickly.

In pressure-pump systems, water hammer is amplified by:

- Oversized pumps driving high flow at relatively low pressure.

- Long, rigid piping with minimal cushioning.

- Undersized pressure tanks or failed expansion devices.

- Faulty or partially closed valves that cause sudden velocity changes.

Callaghan Pump notes that improperly sized or failing pressure regulators can also push system pressure too high, making the entire plumbing network more prone to hammering and humming.

Besides being startling, water hammer is bad news for the health of your water system. It stresses fittings, joints, and fixtures; can crack brittle plastic filter housings; and may disturb settled deposits inside pipes.

In a home hydration context, this might look like a booster pump feeding a whole-house filter and UV unit, set to maintain high pressure for multiple showers at once. If a fast-closing faucet or solenoid valve downstream shuts abruptly, the pressure wave can slam through the system, shaking pipes and making the pump sound louder even though the root cause is the piping dynamics.

Solving water hammer typically involves a professional review of pipe layout, pressure tank sizing, valve selection, and pressure settings, especially if you already rely on a complex filtration and softening train.

Mechanical Wear, Misalignment, And Mounting Problems

Hydraulic noise is only half the story. Numerous sources, including Envirowaste, Enviro Waste, Streampumps, Yimaipump, Pumptec, Winston Engineering, and Epp Well Solutions, emphasize that mechanical wear often reveals itself audibly before catastrophic failure.

Bearings And Seals – The “Voice” Of Rotating Parts

Bearings support the rotating shaft of the pump and motor. When healthy and properly lubricated, they contribute only a modest, high-frequency component to the hum. When they start to fail, they often become the main actor in your noise drama.

Envirowaste and Yimaipump both note that bearing wear tends to create high-pitched squeals or grinding sounds, often accompanied by increased vibration and hotter bearing housings. Winston Engineering and Vertisys add that overload, poor or excessive lubrication, misalignment, contamination, and corrosion all accelerate bearing wear.

Signs that bearings are the culprits include:

- A squeal or screech that tracks with pump speed, even when valves are throttled.

- Roughness or “sandiness” if you turn a disconnected motor shaft by hand during professional inspection.

- Time-based progression: the noise gradually worsens over days to weeks.

In well pump systems, Epp Well Solutions observes that worn bearings become common after about ten to fifteen years for many jet pumps and after roughly fifteen to twenty-five years for submersibles, especially where maintenance has been neglected. While your home booster may not see the same duty cycle, the pattern is instructive: bearings are wear items with a long but finite life.

Seals and packing also contribute. Pumptec and Winston Engineering describe how worn seals and leaking inlet plumbing allow air into the system, producing very loud noises similar to cavitation. They also let moisture into bearing housings, leading to rust and accelerated failure, a progression also discussed in Streampumps’ abnormal noise guide.

A practical example is a basement-mounted booster pump that has slowly wept at its shaft seal onto the motor foot. Over months, moisture and dust create a gritty paste; bearings run hotter and lose grease. One day you notice a new, sharp squeal when the pump starts and a distinct vibration in the floor. By catching this early, a technician can replace bearings and seals, rather than the entire pump.

Impeller Damage, Debris, And Rubbing

Impellers are the “fan” that moves water in most pumps. When intact and clean, they run true and quiet. Enviro Waste, Envirowaste, Streampumps, Pump Repair Services, and Yimaipump all point out that:

- Debris such as sand, rust, or scale caught in the impeller clearance causes rattling or grinding.

- Cracked, bent, or imbalanced impeller blades lead to vibration and humming.

- Impeller rubbing the casing creates sharp, metal-on-metal friction noise.

Streampumps provides practical diagnostic cues: friction noise from the pump head that does not change significantly when you throttle the outlet, but does vary with speed, often indicates internal rubbing or foreign objects. Manual rotation during inspection reveals large or small-angle resistance that repeats periodically, which technicians use to confirm the issue.

In home filtration systems, debris often originates upstream:

- Sediment from a well or rainwater cistern.

- Rust and scale from older galvanized pipes.

- Media fines from certain filter cartridges if not flushed properly.

This is one reason so many manufacturers and service providers, including Envirowaste and Envirowaste’s noisy-pump guide, stress installing and maintaining strainers or prefilters ahead of the pump. A relatively inexpensive screen can prevent more than half of pump repair needs by stopping debris before it reaches impeller clearances, according to Hydparts’ troubleshooting recommendations.

Misalignment, Loose Hardware, And Structural Vibration

A pressure pump rarely operates in isolation. It is bolted to a base, connected to piping, and often coupled to a motor. Multiple sources including Winston Engineering, Pumptec, Hydparts, Streampumps, Vertisys, and Envirowaste emphasize that poor installation can transform a modest amount of pump vibration into a loud, structure-borne nuisance.

Common mechanical-installation issues include:

- Loose mounting bolts allowing the pump to rattle and transmit vibration into floors and walls.

- Misaligned coupling between pump and motor causing rhythmic knocking and additional wear.

- Piping that is too rigid, too long, or poorly supported, turning walls into sounding boards.

- Foundations that resonate, especially when there is an enclosed air cavity under the base, producing low continuous “drum” noise, as described in Streampumps’ guide.

A simple real-world illustration is a compact booster pump mounted directly to a thin plywood panel on a basement wall, with rigid copper pipes running vertically up into the house. When the pump was new and quiet, the homeowner barely noticed. After a bearing began to wear, the combination of increased vibration and the “speaker panel” wall magnified the sound into the living room above. The actual mechanical repair was straightforward, but adding rubber isolation mounts and flexible connectors at the same time dramatically reduced noise.

Electrical And Control-Related Noise

Electrical and control issues seldom create noise directly in the water, but they change how the motor behaves. Enviro Waste, Envirowaste, Epp Well Solutions, Streampumps, Vertisys, and Yimaipump all identify electrical problems as key culprits when the pump hums, buzzes, or overheats.

Humming Without Flow – When The Motor Struggles

A pump that suddenly begins humming loudly while delivering little or no pressure is a red flag. Envirowaste and Pump Repair Services note that humming often points to:

- Faulty start or run capacitors.

- Relays or contactors failing to engage properly.

- Low or unstable supply voltage, common in some rural settings.

Epp Well Solutions expands on this for well pumps, explaining that low voltage or power surges can prevent motors from starting cleanly, causing persistent buzzing and rapid overheating. In submersible and jet pumps alike, faulty control-box capacitors and relays are common causes of humming and failed starts.

From a homeowner’s perspective, the key signs are:

- The pump energizes and hums when a faucet opens, but water pressure does not build as it normally would.

- The noise is present even if you briefly close all valves at the pump discharge.

- Components in the control box feel abnormally warm or smell slightly burnt, although you should never open electrical enclosures yourself.

Because electrical faults can damage motors quickly and pose shock hazards, most sources, including Envirowaste and Pump Repair Services, advise homeowners to treat humming with poor flow as a “call a professional” situation rather than a DIY project.

Variable-Speed Drives And High-Frequency Whine

As more homes adopt variable-speed booster pumps for better pressure control and energy savings, another noise source emerges: the drive electronics themselves. Streampumps notes that variable-frequency drives can produce continuous high-pitched sound if the carrier frequency is poorly matched to the motor, while Vertisys points out that incorrect speed settings or poor grounding in variable-speed pumps can lead to electrical noise and system humming.

While this type of noise is often less dangerous than cavitation or grinding bearings, it can be irritating in living spaces. Smart adjustment of drive settings and proper grounding, typically performed by a technician, can often shift inverter noise out of the most noticeable frequency range and reduce overall acoustic impact.

Quick Homeowner Triage When Noise Suddenly Spikes

When you first notice a sudden increase in pump noise, a calm but deliberate response helps protect both your equipment and your home hydration reliability. Guidance from Allied Pumps, Enviro Waste, Envirowaste, Pump Repair Services, and Epp Well Solutions points to a structured approach.

Start by observing what the pump is doing when the noise appears. If the noise only occurs when water is flowing and changes as you open or close faucets, hydraulic causes such as cavitation, air, or water hammer are more likely. If the noise persists even when valves are throttled and flow is low, mechanical or electrical issues climb higher on the list.

Next, consider whether flow and pressure feel normal. If your usual shower pressure is weak while noise has increased sharply, that combination often points toward cavitation, air entrainment, or clogging, as emphasized by Pumpworks and Hydparts. If pressure is normal but the pump sounds rougher or more rattly, mechanical wear or loose hardware may be more likely.

Allied Pumps suggests a technique in industrial settings to distinguish mechanical from hydraulic noise by briefly running the pump without water. However, most small home booster and well pumps can be damaged quickly by dry running. For home hydration systems, it is safer to avoid deliberate dry-run tests and instead lean on simple observational diagnostics and professional help when needed.

If you notice loud grinding, banging, or a smell of overheating, shut down the pump and isolate power at the breaker if it is safe to do so. Allied Pumps emphasizes never opening a hot pump, as internal pressure and temperature can cause injury; allow it to cool before any inspection. At the same time, remember that shutting down a pressure pump may interrupt your water supply. If family members rely on continuous filtered water or medical devices fed by the system, plan for bottled water or an alternate source while the issue is investigated.

As a practical example, imagine this scenario. At 7:00 PM, your under-sink booster pump feeding your kitchen filtration system begins to make a sharp crackling sound whenever you fill a pot, and the stream pulses instead of flowing smoothly. You note that whole-house pressure is slightly lower than usual. Based on patterns described by Envirowaste and Hydparts, those symptoms lean toward cavitation or air issues. You check the clear prefilter bowl and discover a heavy layer of sediment, and the small suction valve that was recently serviced is only half open. Correcting valve position and replacing the filter cartridge may restore quiet operation in minutes, avoiding further damage.

By contrast, if the same pump hums loudly when you open the faucet but no water flows, and it remains noisy even after you close the faucet again, that points toward an electrical or mechanical stall. In that case, powering down and calling a qualified technician is the safest move.

Repair, Replace, Or Upgrade – Making A Smart Decision

Once you have identified a likely noise source and taken immediate protective steps, the next decision is whether to repair the existing pump, replace it, or upgrade the system. Multiple sources provide useful decision cues.

Envirowaste suggests that repair is usually preferred when problems are minor and the pump is relatively young, often under about five years, especially for issues like small leaks, worn bearings, or removable debris. Epp Well Solutions notes that many mechanical repairs on well pumps, such as bearing replacement, fall into moderate cost ranges, and that replacing worn components can add many years of life when the pump body itself is sound.

On the other hand, Envirowaste and Epp Well Solutions both recommend replacement when the pump is older, often over about ten years, has extensive internal damage, or has a pattern of frequent breakdowns and reduced efficiency. Yimaipump further suggests that if repair costs approach roughly half the price of a comparable new pump, replacement often makes more economic sense.

Becker Pumps adds an important nuance: decisions cannot be made by sound level alone. A quiet pump can still be inefficient or damaged internally, and a somewhat loud but well-isolated pump might be perfectly healthy. A physical inspection and performance check are essential.

From a smart hydration perspective, it often makes sense to view this decision in terms of water wellness and convenience, not just dollars. Replacing a noisy, marginally sized booster with a modern variable-speed unit can deliver:

- Quieter operation, especially if paired with better mounting and flexible connections.

- More stable pressure for showers and filtration systems, which helps maintain consistent filter performance.

- Improved efficiency, lowering long-term energy costs.

In a home where the pump is the backbone of both drinking water and hygiene, the peace of mind and reliability gained from an upgrade may justify replacement earlier than in a purely industrial setting.

Preventing Future Noise And Protecting Water Quality

Prevention is the most cost-effective “noise control program” you can run. Many of the sources reviewed, including Envirowaste, Enviro Waste, Hydparts, Yimaipump, Pumptec, Streampumps, and Vertisys, converge on similar best practices.

Schedule basic inspections on a regular cadence. Enviro Waste suggests checking for leaks every three to six months, lubricating bearings roughly every six months where applicable, inspecting electrical components about once or twice a year, and testing water pressure monthly. Folding those checks into your seasonal home-maintenance routine makes them more realistic.

Keep filters and strainers clean. Envirowaste and Hydparts emphasize that clogged strainers and suction filters are leading triggers of cavitation and noisy operation. Replacing or cleaning prefilters at least annually, or more often for sediment-heavy wells or rainwater systems, not only improves water quality but protects your pump’s hydraulic health.

Monitor for small leaks and address them promptly. Pumptec and Winston Engineering warn that leaking inlet plumbing and seals allow air into the suction side, creating very loud, destructive operating conditions that mimic cavitation. They also allow water to reach bearings and mounting hardware, setting the stage for corrosion and future noise.

Ensure proper installation and alignment from the beginning. Enviro Waste, Streampumps, Vertisys, and Winston Engineering all present improper installation as a major root cause of noise. That includes pump location, base design, coupling alignment, and pipe routing. In hydration-focused homes, placing pumps in utility spaces with solid foundations, using vibration-isolating mounts, and running flexible connectors to rigid piping can dramatically reduce transmitted noise.

Match pump selection to your system’s actual needs. Vertisys and Callaghan Pump highlight the problems with both oversized and undersized pumps. Oversized pumps tend to be noisy, cause water hammer, and force you to throttle flow wastefully. Undersized pumps run hot and loud as they struggle to meet demand, making them prone to deadheading and cavitation. For well systems, Epp Well Solutions recommends matching pump capacity to well yield to avoid over-pumping; for booster systems, you should match flow and pressure to your fixture count, piping, and filtration load.

Finally, pay attention to sound trends, not just catastrophic changes. Hydparts and academic work on audio diagnostics show that subtle changes in noise spectrum can appear before obvious performance drops. At home, you do not need specialized microphones or FFT software; simply make it a habit, once a month, to stand near your pump while a faucet is running and notice how it sounds.

If it is clearly louder, rougher, or more erratic than you remember, that is the time to investigate, not when it fails entirely.

Short FAQ

Q: Is a sudden increase in pump noise always dangerous, or can I ignore it if water still flows normally?

A: Persistent new noise is rarely harmless. Technical guidance from Hydparts, Pumptec, and Envirowaste consistently frames unusual loudness as an early symptom of cavitation, air problems, mechanical wear, or electrical faults. Even if flow feels acceptable today, running a noisy pump often accelerates wear and raises the chance of sudden failure or leakage that can disrupt your hydration system at inconvenient times. It is better to investigate early while repairs are simpler.

Q: How can I tell if the noise is coming from the pump itself or from my pipes?

A: A practical approach, based on advice from Enviro Waste, Streampumps, and Winston Engineering, is to gently place your hand on the pump housing and nearby piping while the noise is present. If the pump body itself vibrates strongly and the sound is loudest right at the casing, the source is likely internal to the pump or motor. If the pump feels fairly smooth while pipes bang or resonate further away, system-side issues such as water hammer, poor supports, or air pockets in the plumbing are more probable. Both situations warrant attention, but the fix may focus more on the pump or more on the pipework depending on what you feel and hear.

Q: Can a noisy pressure pump affect the quality of my drinking water, or is it just a comfort issue?

A: The main risk from pump noise is reliability, not direct contamination, but there are indirect links to water quality. Cavitation and debris-related grinding can erode metal surfaces, potentially releasing fine particles into the water path. More importantly, a failing pump can leave you without pressure for filtration and UV treatment at critical times, which directly affects your access to safe water. By addressing noise proactively, you are not just protecting your ears; you are protecting the continuity and safety of your home hydration system.

Closing

Sudden pump noise is your system’s way of asking for attention. When you listen with a smart, methodical mindset, you turn that annoyance into an asset, catching cavitation, wear, and wiring issues before they threaten your water supply. As a water wellness advocate, my core advice is simple: if your pressure pump suddenly gets louder, do not ignore it, and do not panic. Observe, make sensible first checks, then partner with a qualified pump or water-treatment professional to keep your filtration and hydration running quietly, efficiently, and safely for years to come.

References

- https://www.academia.edu/129524879/Diagnosing_Mechanical_and_Hydraulic_Faults_in_Centrifugal_Pumps_using_Audio_FFT_Analysis

- https://digitalcommons.mtu.edu/cgi/viewcontent.cgi?article=2534&context=etdr

- https://docs.lib.purdue.edu/cgi/viewcontent.cgi?article=3443&context=icec

- https://ui.adsabs.harvard.edu/abs/2025PhFl...37g7185L/abstract

- https://epubl.ktu.edu/object/elaba:17200540/17200540.pdf

- https://oaktrust.library.tamu.edu/bitstream/handle/1969.1/164112/P15143-155.pdf?sequence=1&isAllowed=y

- https://chem.uiowa.edu/sites/chem.uiowa.edu/files/2024-04/TN3501-SEC-MALS-Noise-Assessment-Guide-Rev-A.pdf

- https://websites.umass.edu/shwalker/2023/06/09/pump-high-pressure-hydraulic-pumps-a-comprehensive-guide-to-rexroths-products/

- https://www.vertisys.net/circulating-pump-noise-and-how-to-fix/

- https://www.aahfluidpower.com/what-are-some-of-the-common-reasons-my-pump-might-be-making-excessive-noise

Share:

Understanding How to Assess the Lifespan of RO Membranes

Understanding Common Issues After Replacing Water Filters