Clean, great-tasting water is one of the simplest “health upgrades” you can give your household. In practice, the conversation almost always comes down to carbon: should you trust tried-and-true granular or block activated carbon, or is it worth paying more for newer carbon fiber filters?

From the perspective of a Smart Hydration Specialist who spends a lot of time looking at real-world systems, both are powerful tools for improving water quality, but in different ways. Under the marketing terms, they share a common core technology—activated carbon—and differ mainly in how that carbon is formed, packaged, and used inside a filter.

In this guide, I will walk through what the science actually says about both media, how they perform in home water systems, and how to decide which makes sense at your faucets, under your sinks, and at your main water line.

The Science Under The Hood: How Carbon-Based Filters Really Work

Before comparing carbon fiber and traditional activated carbon, it helps to be clear on the underlying mechanism. Much of the confusion in the filtration world comes from mixing up basic definitions.

At the heart of both technologies is activated carbon, sometimes called activated charcoal. As described by water treatment providers such as Aqua Clear Water Systems and Culligan, activated carbon is made by heating carbon-rich materials like coconut shells, wood, or coal at very high temperatures. This process burns off impurities and creates a network of cracks and pores. The result is an incredibly porous material with a huge internal surface area.

The U.S. Environmental Protection Agency has noted that just one gram of activated carbon can offer up to roughly 1,400 square meters of surface area. Converted to imperial units, that is on the order of fifteen thousand square feet of internal surface area in something that weighs less than a paperclip. That massive interior landscape is where the real work happens.

Adsorption, Not Absorption

Technical sources such as AirScience and multiple filtration manufacturers emphasize a key distinction: adsorption versus absorption.

Absorption is what happens when a sponge soaks up water; the liquid penetrates into the bulk of the material. Adsorption, by contrast, is a surface phenomenon. Molecules of chlorine, volatile organic compounds (VOCs), and other pollutants stick to the surface of the carbon’s internal pores without being absorbed into the bulk.

Both air and water treatment articles in this research set repeatedly highlight adsorption as the main mechanism for carbon filters. Clean-Link explains that when air passes through an activated carbon filter, contaminants are held on the surface of the carbon particles. Culligan and Aqua Clear Water Systems describe the same process in water: as water flows through, unwanted molecules cling to the massive internal surface of the carbon.

Because adsorption is surface-driven, three things matter most for performance, as Culligan outlines.

First is surface area. More internal area means more “parking spaces” for contaminants. Second is contact time. The longer water stays in contact with the carbon, the more chances contaminants have to stick. Third is filter design. Granular beds, solid blocks, and fiber-based media all manage flow and contact time differently.

What Traditional Activated Carbon Removes (And What It Doesn’t)

Across sources like Aqua Clear Water Systems, Culligan, One Green Filter, and BIS Research, there is strong agreement on what properly designed activated carbon filters can do in water treatment.

They are consistently effective at reducing chlorine and chloramines, which are widely used in municipal disinfection but cause unpleasant taste and odor. They remove many pesticides and herbicides, a broad class of organic chemicals, and a wide range of VOCs. Some systems and media formulations can also reduce certain heavy metals, and high-quality activated carbon has been described by One Green Filter as able to capture microplastics.

Culligan notes that activated carbon can also reduce trihalomethanes, which are byproducts formed when chlorine reacts with natural organic matter, and that appropriate carbon designs can reduce some PFAS compounds depending on the water chemistry. At the municipal scale, BIS Research highlights granular activated carbon beds as one of the main tools utilities use to polish treated water and tackle emerging contaminants like PFAS.

However, Aqua Clear Water Systems and Culligan are equally clear on the limitations. Standard activated carbon filters by themselves do not reliably remove bacteria or viruses. They do not fix water hardness because they do not remove dissolved minerals like calcium and magnesium. They do not effectively remove nitrates and nitrites or reliably address fluoride. For those issues, suppliers recommend pairing carbon with ion exchange softeners, reverse osmosis membranes, and ultraviolet disinfection or other dedicated technologies.

In practice, this is why most high-performance whole-house systems are multi-stage.

Sediment pre-filters handle grit, carbon takes care of taste, odor, and many chemicals, and additional stages focus on hardness and microbiological safety.

Traditional Activated Carbon In Home Water Systems

When people talk about “carbon filters” for water, they usually mean one of two formats that Aqua Clear Water Systems and Culligan describe: granular activated carbon (GAC) and carbon block.

Granular activated carbon consists of loose particles. Water flows through a bed of granules, which provides a relatively high flow rate. This makes GAC a common choice for point-of-entry systems that treat all the water coming into a home. Guidance from the Minnesota Department of Health describes whole-house GAC filters as tall cylindrical tanks, around 4 feet tall and 15 inches in diameter, often installed in pairs. In that configuration, water flows through one tank and then the next; when the first is exhausted, the second is moved into the lead position and a new tank is added behind it.

Carbon block filters compress the granules into a dense, solid block. This lowers the flow rate but increases contact time and can improve contaminant removal, especially for chlorine, VOCs, and many taste and odor compounds. Carbon blocks are widely used in refrigerator filters, under-sink cartridges, and pitcher-style filters because they can pack a lot of performance into a compact housing.

Both GAC and carbon block are often also used inside reverse osmosis systems. Culligan describes configurations where carbon is placed before the membrane to protect it from chlorine and organic foulants, and again after the membrane as a “polishing” stage that ensures the final water tastes and smells clean.

From a home hydration perspective, the key point is that these traditional carbon formats are well-understood, widely used in municipal, industrial, and residential systems, and have decades of field experience and regulatory guidance behind them.

What Are Carbon Fiber Filters And How Do They Differ?

The term “carbon fiber filter” can be confusing because it is used in at least two different ways in the filtration world.

On one side, there is structural carbon fiber: a strong, lightweight material made of more than 90 percent carbon atoms arranged in a crystalline structure. According to the comparative analysis from Sutong Carbon Fiber, these fibers can be seven to nine times stronger than steel while having less than a quarter of the density. They are prized in aerospace, automotive, marine, and sports equipment for their strength-to-weight ratio and corrosion resistance, not primarily for filtration.

On the other side, there are filtration media built from carbon-based fibers. Sutong Carbon Fiber describes activated carbon cloth as a porous fabric made by loading a textile with powdered activated carbon and then activating it to dramatically increase surface area. This activated carbon cloth combines flexibility and high adsorption capacity, enabling it to capture gases, chemicals, odors, and some bacteria, and the article notes it is used in both air and water purification systems and in protective garments.

A separate article from Antfilter focuses on carbon fiber filters for air. It explains that these filters use layers of activated carbon bonded with synthetic fibers. The composite material is lightweight and durable yet offers a large surface area and can handle high air volumes while adsorbing gases, VOCs, smoke, and odors that ordinary mechanical filters miss. Antfilter also notes that these filters maintain efficiency even in high humidity and typically last about three to six months in household conditions before replacement is needed.

In the water space, SJ Wave provides an example of faucet filters that use what the company calls advanced carbon fiber filtration.

Their description states that this media is claimed to be ten times more efficient than “normal active carbon filters,” removing about 98 percent of chlorine, taste, and odor while blocking fine particles, heavy metals, and other contaminants and preserving beneficial minerals. Each compact faucet filter is rated for about 320 gallons of filtered water.

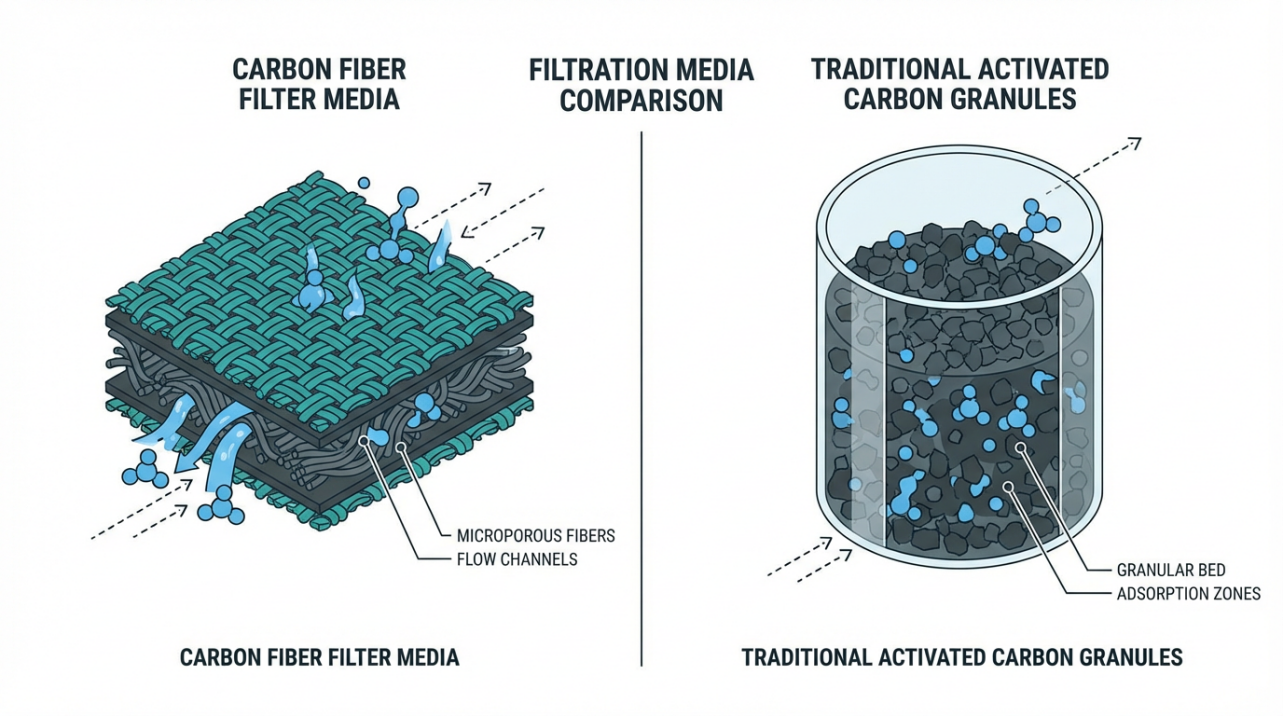

When you put these sources together, a clear pattern emerges. Carbon fiber filters for water are not a totally different technology; they still rely on activated carbon and adsorption. The key distinction lies in how the carbon is shaped and supported. Instead of loose granules or a solid block, the carbon is integrated into a fibrous or cloth-like medium that can be made very thin while providing substantial surface area.

Side-By-Side: Carbon Fiber Media vs. Granular And Block Activated Carbon

It is helpful to look at the main differences across a few practical dimensions. The table below synthesizes information from the research sources above.

Dimension |

Carbon Fiber Media (including activated carbon cloth and carbon fiber faucet filters) |

Granular / Block Activated Carbon (traditional GAC and carbon blocks) |

Core mechanism |

Uses activated carbon in a fibrous or cloth structure; adsorption onto internal pore surfaces |

Uses activated carbon in loose granules or compressed blocks; adsorption onto internal pore surfaces |

Media form |

Thin, flexible layers of carbon-loaded fibers or cloth; often bonded to synthetic substrates |

Loose granules in a bed (GAC) or dense, rigid carbon blocks |

Typical uses (documented) |

Air purifiers, HVAC and ventilation filters, vehicle cabins (Antfilter); water purification systems and protective garments for activated carbon cloth (Sutong); faucet water filters in at least one product line (SJ Wave) |

Whole-house water filters, municipal and industrial beds (Minnesota Department of Health, BIS Research); refrigerator, pitcher, and under-sink drinking-water filters; pre- and post-filters around reverse osmosis membranes (Aqua Clear Water Systems, Culligan) |

Claimed performance highlights |

Manufacturer claims of strong gas and odor removal in air (Antfilter); SJ Wave claims about 98 percent chlorine, taste, and odor reduction and higher efficiency vs standard active carbon in a faucet filter |

Broadly documented removal of chlorine, chloramines, many VOCs, pesticides, organic chemicals, and improvement in taste and odor; certain designs reduce some heavy metals, microplastics, trihalomethanes, and some PFAS compounds (Aqua Clear Water Systems, Culligan, One Green Filter, BIS Research) |

Design flexibility |

Highly flexible; cloth and fiber media can be cut and shaped, which Sutong highlights for activated carbon cloth integration into various purification products |

Modular tank and cartridge designs; cylindrical whole-house filters, standard-sized cartridges and blocks that fit many housings; easy to scale capacity by adding tanks or stages |

Lifespan and replacement (examples) |

Antfilter reports carbon fiber air filters typically last three to six months in household conditions; SJ Wave rates a carbon fiber faucet filter for about 320 gallons |

One Green Filter notes that many carbon cartridges last from a few months to about a year depending on usage and model; Culligan describes replacement intervals in terms of months and emphasizes following certified system guidance |

Evidence base |

Promising performance claims but relatively limited third-party, water-specific data in the sources provided; product-specific claims may not generalize |

Long track record in municipal, industrial, and residential water treatment; performance and limitations extensively documented in utility guidance and manufacturer literature |

The takeaway from this comparison is that carbon fiber media is essentially a new way to deploy activated carbon, not a fundamentally different chemical process.

Whether it outperforms traditional formats depends heavily on the specific product design, how much activated carbon is actually present, and how the filter is used.

Contaminant Removal: Where Each Technology Shines

From a water wellness perspective, what matters most is what ends up in your glass. The notes across these articles allow some careful, evidence-based comparisons.

For chlorine, taste, and odor, both traditional activated carbon and the carbon fiber faucet filters described by SJ Wave are designed to perform very strongly. Aqua Clear Water Systems, Culligan, and One Green Filter all emphasize that activated carbon is one of the best ways to remove chlorine and many organic taste and odor compounds from tap water. This is why carbon is a standard stage in refrigerator filters, under-sink cartridges, and whole-house systems.

SJ Wave goes further and claims that their carbon fiber faucet filters remove about 98 percent of chlorine, taste, and odor while leaving beneficial minerals. Those figures are manufacturer-specific; they show what a well-designed carbon fiber cartridge can do, but they should not be automatically assumed for every carbon fiber product on the market.

For organic chemicals—including many pesticides, herbicides, and VOCs—traditional activated carbon has a long documented record. Aqua Clear Water Systems describes its ability to remove pesticides, VOCs, and many organic chemicals in water. Culligan notes reduction of VOCs and trihalomethanes, and One Green Filter highlights activated carbon’s ability to deal with a broad spectrum of contaminants, including microplastics in some configurations. BIS Research underscores that granular activated carbon is widely used in municipal systems precisely because of its effectiveness against many organic pollutants and its role in tackling emerging contaminants like PFAS when properly implemented.

For metals and particles, the picture is more nuanced. Aqua Clear Water Systems notes that activated carbon can remove certain heavy metals, and SJ Wave claims that its carbon fiber faucet filters block heavy metals and fine particles while preserving minerals. At the same time, Culligan cautions that standard carbon filters alone do not typically handle heavy metals such as lead or arsenic unless combined with additional treatment methods. This suggests that while specific carbon or carbon-fiber-based products can be formulated to target metals, you should not assume any carbon filter will do so; you need to verify the specific performance claims for the model you are considering.

For microplastics and other particulates, One Green Filter reports that high-quality activated carbon systems can capture very small particles like microplastics.

SJ Wave describes its carbon fiber faucet media as blocking fine particles and other contaminants. However, neither carbon nor carbon fiber media are primary tools for removing very fine particulates or biological contaminants in water. For microbes, Aqua Clear Water Systems and Culligan both state that activated carbon does not reliably remove bacteria or viruses. That is why UV disinfection and reverse osmosis membranes are often added when microbiological safety is a concern.

For dissolved minerals and hardness, both carbon fiber and traditional activated carbon are in the same boat. Aqua Clear Water Systems explains that activated carbon does not address hardness minerals like calcium and magnesium, and Culligan notes that dissolved salts and minerals pass through carbon. If your primary issues are scale, soap scum, or appliance damage from hard water, an ion exchange water softener is the correct technology, with carbon acting as a complementary stage for chemicals and taste.

Flow, Contact Time, And Everyday Experience

One of the differences families notice immediately when they change filters is how water feels at the tap: whether flow slows down, pressure drops, or taste changes.

Aqua Clear Water Systems explains that granular activated carbon allows higher flow rates because the granules leave more open space for water to move through. In contrast, carbon block filters compress the particles into a denser structure; this naturally slows flow, but it increases contact time and can boost contaminant removal. Culligan echoes this, noting that filter design and contact time are critical to performance.

For carbon fiber media, the air filtration article from Antfilter gives some useful clues. It notes that carbon fiber filters are designed to be lightweight and to maintain good airflow while offering a large surface area for adsorption. In air systems, this means they can treat high volumes without drastic pressure drops. In water, a similar design principle applies: fiber and cloth media can often be made thin and pleated to increase surface area while keeping resistance manageable. However, the actual flow and performance still hinge on how the water path is engineered inside the cartridge.

In practical terms, for a whole-house system where showers, washing machines, and dishwashers demand many gallons per minute, large GAC tanks have proven themselves capable of handling those flows while still delivering meaningful chlorine and chemical reduction.

For a single drinking-water faucet, a carbon block or carbon fiber cartridge can afford to sacrifice a bit of flow to gain more contact time and polishing performance, as long as the everyday user experience remains comfortable.

A consistent theme across Culligan and Aqua Clear Water Systems is that faster is not always better. If water moves too quickly through any carbon medium, carbon fiber or not, there simply is not enough time for adsorption, and removal drops. Good system design balances flow, pressure, and contact time to meet both performance and comfort goals.

Saturation, Lifespan, And Maintenance

All carbon-based filters share one inconvenient truth: once the adsorption sites are full, performance drops off sharply.

Oransi and AirScience both emphasize that activated carbon has a finite adsorption capacity. Once those internal surfaces are saturated with captured molecules, breakthrough occurs and contaminants start slipping through. At that point, the filter must be replaced or the media regenerated in a specialized facility.

Antfilter notes that in air systems, a typical carbon fiber filter lasts about three to six months in household conditions, with more frequent changes in higher-pollution environments. It recommends looking for signs like reduced airflow and lingering odors as indicators that replacement is due.

In water, One Green Filter states that most carbon cartridges need replacement somewhere between every few months and about a year, depending on the specific model and usage. Culligan similarly describes replacement intervals in terms of months and stresses that filters for certified systems are designed with specific lifespans in mind. SJ Wave specifies its carbon fiber faucet filter lifespan in gallons—about 320 gallons of water per filter. The higher the daily water use through that faucet, the faster you reach that limit.

For whole-house GAC systems, the Minnesota Department of Health describes an arrangement where tanks are installed in series, with sampling ports before, between, and after the filters. Water can be tested at each port to determine when the first tank is exhausted. At that point, the second tank is moved to the first position, and a new tank is installed behind it. This approach ensures that contaminants are captured even as the first media bed nears saturation.

The practical lesson is that you cannot “set and forget” any carbon-based filter. Whether it uses granules, blocks, cloth, or carbon fiber, you should follow the manufacturer’s gallon ratings or time intervals, watch for changes in taste and odor, and, when available, use built-in indicator lights or sampling ports to confirm performance.

Real-World Use Cases: When To Favor Each Option

In day-to-day home hydration projects, the right carbon media depends less on brand-new buzzwords and more on where the filter sits in your plumbing and what it needs to accomplish.

For whole-house protection against chlorine, many VOCs, and better overall smell and feel of water at every tap and shower, the research and public health guidance available focus on granular activated carbon tanks. The Minnesota Department of Health’s examples and the way companies like One Green Filter and Culligan design point-of-entry systems all rely on GAC or similar bulk media for this job. Here, the sheer volume of water and the need for robust, easily serviceable tanks make traditional granular media the practical choice.

For under-sink systems and reverse osmosis units that feed a dedicated drinking-water faucet, carbon block filters are widely used and thoroughly characterized. Aqua Clear Water Systems and Culligan describe setups where a carbon stage protects the RO membrane from chlorine, and another carbon stage polishes the permeate, ensuring that water used for drinking and cooking has excellent taste and smell.

For compact faucet filters where space is at a premium and installation needs to be simple, carbon fiber media offers an intriguing design advantage. SJ Wave’s faucet filters, as one example, pack significant claimed performance into a small form factor: high chlorine, taste, and odor reduction; blocking of fine particles and heavy metals; and a 320 gallon rating, all while maintaining beneficial minerals. That sort of combination is attractive for renters or anyone who cannot or does not want to modify plumbing.

For air and water together, families who are sensitive to odors and chemical fumes sometimes choose carbon filtration in both domains. Oransi, Camfil, and others make the case for activated carbon filters in air purifiers and HVAC systems to capture VOCs, toxic gases, and odors that HEPA filters alone do not address. At the same time, water treatment providers rely on carbon filters to remove many of the same classes of chemicals from drinking water. While the media formats differ, the underlying adsorption chemistry is shared.

In environments requiring extreme structural strength and chemical durability—such as industrial reactors, marine structures, or high-performance sports gear—the Sutong Carbon Fiber analysis shows why structural carbon fiber is preferred. In those cases, filtration is secondary or irrelevant; strength and weight dominate the design.

How To Decide What Is Right For Your Home

The most reliable way to choose between carbon fiber filters and traditional activated carbon is to start with your water and your goals, not with the technology.

Culligan explicitly recommends beginning with a professional water test. That test identifies whether your main issues are chlorine and taste, organic chemicals and VOCs, heavy metals, nitrates, hardness, microbes, or some combination. Once you have that baseline, the role of carbon becomes clearer.

If your primary concern is taste and chlorine in otherwise safe municipal water, a well-designed carbon block or a carbon fiber faucet filter can both be excellent choices. In that scenario, the decision often comes down to convenience, cost per gallon, and whether a specific product’s performance claims—such as SJ Wave’s reported 98 percent chlorine, taste, and odor reduction—fit your needs and budget.

If you need broader chemical control, including pesticides, many VOCs, trihalomethanes, and emerging contaminants like some PFAS compounds, the evidence base for traditional granular and block activated carbon is deeper. Municipal-scale systems, whole-house filters, and multi-stage treatment setups described by Aqua Clear Water Systems, BIS Research, and Culligan all rely heavily on these media.

If heavy metals, nitrates, fluoride, or microbiological safety are major concerns, neither carbon fiber nor conventional carbon should be your only line of defense. Aqua Clear Water Systems, Culligan, and One Green Filter all stress that you will need technologies like ion exchange softeners, reverse osmosis membranes, and UV disinfection alongside carbon. In these combinations, carbon—whether in granular, block, or fiber form—plays a crucial polishing and protective role rather than acting as a standalone solution.

Across all of these scenarios, look for systems whose claims are backed by credible testing and, where possible, third-party certifications. Culligan emphasizes that when properly matched to the local water supply and certified to relevant standards, carbon filters can deliver reliable improvements in both safety and user experience. Pay attention to details such as specified contaminant reduction, rated gallon capacity, recommended replacement intervals, and whether indicator lights or sampling ports are provided to help you know when performance is declining.

Short FAQ

Q: Are carbon fiber water filters really better than traditional activated carbon? A: Carbon fiber filters are another way of presenting activated carbon, not a different chemistry. In at least one faucet filter line described by SJ Wave, carbon fiber media is claimed to be ten times more efficient than normal active carbon and to remove about 98 percent of chlorine, taste, and odor. Those claims, however, are product-specific. Traditional granular and block carbon filters have a much broader body of independent data behind them in both municipal and residential use. The “better” option for your home depends on the particular product, how much activated carbon it contains, how the water flows through it, and what contaminants you need to address.

Q: Can either carbon fiber or standard carbon filters make my water safe from bacteria and viruses? A: The water treatment articles from Aqua Clear Water Systems and Culligan agree that activated carbon by itself does not reliably remove bacteria or viruses. That applies to carbon fiber media as well, because the underlying adsorption mechanism is the same. If microbiological safety is a concern—for example, if you are on a private well or dealing with boil-water advisories—you should pair carbon with disinfection technologies such as UV treatment or with membranes such as reverse osmosis, rather than relying solely on carbon.

Q: Do carbon-based filters fix hard water or remove fluoride? A: No. Both Aqua Clear Water Systems and Culligan point out that activated carbon does not remove the dissolved minerals that cause hardness, nor does it reliably remove fluoride. Carbon can dramatically improve taste, odor, and many chemical contaminants, but if you are battling scale on fixtures and appliances, an ion exchange water softener is the appropriate solution. For fluoride and many dissolved salts, reverse osmosis is typically recommended, often with carbon stages before and after the RO membrane.

Choosing the right filtration media is ultimately about matching proven science to your home’s reality. When you understand that carbon fiber and traditional activated carbon share the same adsorption engine, you can look past the labels and focus on design, testing, and how each option fits into a smart, whole-home hydration strategy that keeps your water clean, appealing, and truly supportive of everyday wellness.

References

- https://digitalcommons.library.uab.edu/cgi/viewcontent.cgi?article=1326&context=etd-collection

- https://pmc.ncbi.nlm.nih.gov/articles/PMC11409178/

- https://www.airscience.com/adsorption-vs-absorption-the-difference-for-carbon-filters

- https://bisresearch.com/insights/how-activated-carbon-is-a-key-solution-in-global-water-treatment

- https://www.culligan.com/blog/what-does-a-carbon-filter-do

- https://espwaterproducts.com/pages/carbon-filters?srsltid=AfmBOoolqBKdbzF-HrapLeAkSSb-MNQKUD1ujCjm9B4SxMJoI5fehnUR

- https://filterking.com/hvac-filters/what-should-you-know-before-buying-a-carbon-air-filter?srsltid=AfmBOoq2rK2d7jDhN7_pV1w8zGK268N8IUc8lzLmJ3MkrtWE6GvBRMhj

- https://www.gzcleanlink.com/the-science-behind-how-activated-carbon-filters-remove-contaminants/

- https://hisoair.com/hepa-vs-carbon-filters/

- https://onegreenfilter.com/reasons-to-upgrade-to-a-carbon-water-filtration-system/

Share:

Why 304 Stainless Steel Faucets Cost More Than Copper Faucets

Understanding Seven-Stage vs Three-Stage RO Systems: How Many Filters Do You Really Need?